Are you worried about your accessory stock running dry in February while your supplier's factory is closed for weeks? Do you fear the post-holiday chaos of delayed shipments, port congestion, and missed sales opportunities? You're facing the annual supply chain event that tests every importer's planning skills. The Chinese New Year (CNY) shutdown isn't just a week off; it's a month-long disruption that ripples through global logistics for months.

The solution isn't a last-minute scramble but a strategic, proactive inventory management plan. Successfully navigating CNY means treating it as a predictable seasonal event, much like planning for Black Friday or Christmas. It requires shifting your mindset from reactive ordering to forecast-based procurement. By understanding the timeline, communicating early with your supplier, and building buffers, you can turn a potential crisis into a competitive advantage, ensuring your shelves stay full and your customers stay happy.

This guide will provide a clear action plan. We will break down the critical CNY timeline, outline strategies for advanced ordering and production scheduling, explain how to navigate the turbulent post-holiday restart, and discuss how to build a resilient inventory system that withstands this annual hiatus. Let's secure your supply chain for the Year of the Snake (or any upcoming zodiac year).

What is the Critical Timeline for Chinese New Year Planning?

The first rule of CNY inventory management is to understand that the factory closure is just the peak of a much longer disruption period. The "holiday" typically lasts 7-15 days for workers, but the operational slowdown begins weeks before and the recovery takes weeks after. Missing a single deadline in this chain can delay your goods by a month or more.

The disruption timeline generally follows this pattern:

- 4-6 Weeks Before CNY: The "last order" deadline. This is your final chance to place orders that can be produced and shipped before the holiday. Factories start prioritizing existing orders and may refuse new ones.

- 2-3 Weeks Before CNY: Production slows significantly. Workers begin traveling home. Quality control and shipping departments wind down.

- CNY Closure (Variable Dates): The factory is completely shut, usually for 1-2 weeks. No production, communication, or shipments occur.

- 1-2 Weeks After CNY: A staggered return to work. Not all workers return immediately (a phenomenon known as "job-hopping"). Factories resume production with existing orders.

- 3-5 Weeks After CNY: Production reaches full capacity. However, a massive backlog of orders from all global clients creates intense competition for raw materials, production lines, and container space. Shipping costs often spike due to this surge.

When is the Absolute Deadline to Place Orders Before CNY?

There is no universal date, as it varies by factory, product complexity, and your logistics method. However, a safe rule of thumb is to finalize all orders and approve all production samples by mid-December for a late January or early February CNY. This means your internal decision-making, sampling, and payment processes must be complete by then. For simpler, in-stock items, the cutoff might be early January. For complex custom accessories requiring new molds and multiple sample rounds, the deadline could be in November. The only way to know for sure is to ask your supplier for their official CNY schedule as early as October or November. A professional partner like Shanghai Fumao Clothing proactively communicates this timeline to clients to ensure seamless planning.

How Does the Post-Holiday Restart Create a "Double Peak" Shipping Crisis?

The post-CNY period creates a perfect storm known as the "double peak." First, all the goods produced right before the holiday rush to ports, causing pre-CNY congestion. Then, after the holiday, a tidal wave of new production from thousands of factories all hits the ports at once in March and April. This leads to:

- Container Shortages: High demand empties depots.

- Skyrocketing Freight Rates: Carriers capitalize on the surge.

- Port Congestion: Ships wait for days to berth.

- Rail & Truck Delays: Inland logistics are overwhelmed.

Your shipment, even if produced on time, can get stuck in this logistical gridlock for weeks. Planning must account for this extended transit time.

How to Strategically Order and Produce Before the Shutdown?

Advanced planning is your most powerful tool. This involves using historical sales data to forecast your needs for Q1 and early Q2, not just for the weeks of the closure itself. You must place a single, larger order (a "pre-CNY bulk order") much earlier than usual to cover the extended lead time gap.

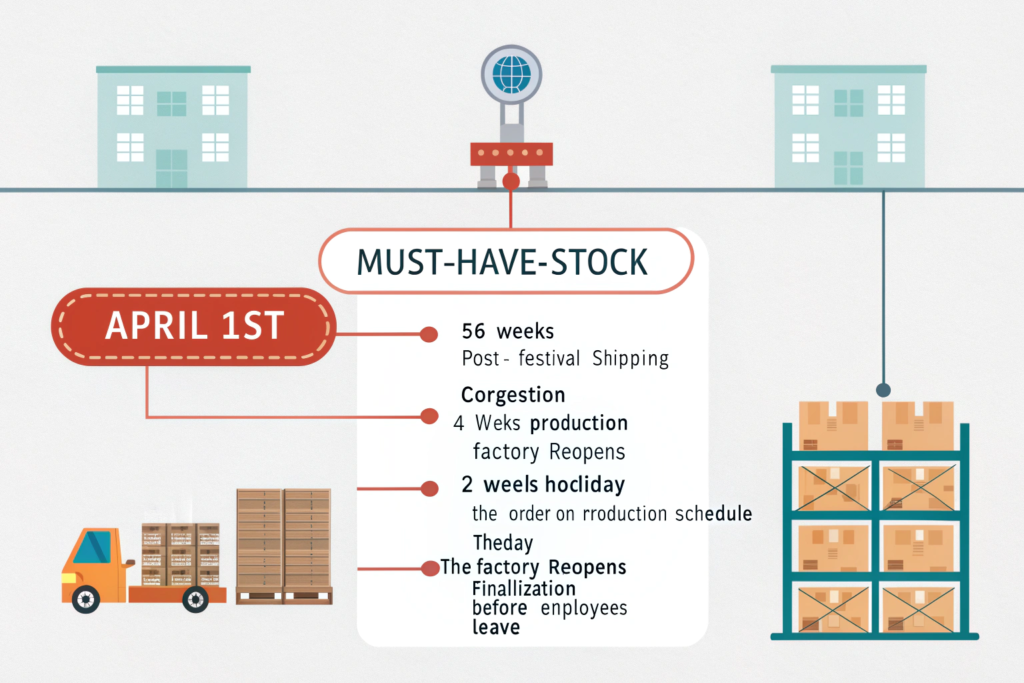

Work backward from your "must-have-stock" date. For example, if you need goods in your warehouse by April 1st, factor in 5-6 weeks for post-CNY shipping and congestion, 4 weeks for production after the factory reopens, and 2 weeks for the holiday itself. This means your order needs to be on the production schedule the day the factory reopens, which requires finalizing everything before they leave. This strategic ordering often means carrying higher inventory levels for a period, which is the calculated cost of continuity.

Should You Use a "Pre-CNY Bulk Order" Strategy?

Yes, for most seasonal fashion accessory businesses, this is the most reliable strategy. Instead of multiple smaller orders, you consolidate demand into one larger order placed 3-4 months in advance. This gives the factory the certainty and time to schedule your production, secure raw materials (like specific acetate for hair clips or fabric for scarves), and complete manufacturing before the pre-holiday rush. While this ties up more capital in inventory, it prevents stockouts that lead to lost sales and damaged customer relationships. It's a classic trade-off between inventory carrying cost and cost of a stockout. For best-selling, classic items (like basic hair bands or best-selling scarves), this strategy is highly recommended.

How Can You Collaborate with Your Supplier on a Production Schedule?

Open communication with your supplier is non-negotiable. Once you have a forecast, schedule a planning meeting (ideally in October/November). Discuss:

- Your estimated quantities for the pre-CNY order.

- Their official factory closure dates.

- Their raw material lead times.

- A detailed, written production schedule with milestones (sample approval, production start, QC, shipping date).

A good supplier will co-create this schedule with you. Ask if they offer pre-holiday production slots that can be reserved. Ensure your payment terms are aligned to release funds in time for them to procure materials. This collaboration turns your supplier into a true partner in your inventory planning, similar to the principles of building a reliable partnership.

How to Navigate the Post-CNY Restart and Logistics Rush?

When the factory reopens, your job shifts from planning to active navigation. The restart is messy. Your first priority is to get confirmation that your order is in the first wave of production. Constant, gentle follow-up is key. Don't assume your order is automatically at the front of the line; confirm its position in the queue.

Simultaneously, you must book shipping space early. As soon as you have an estimated completion date (ETD) from the factory, work with your freight forwarder or the supplier's logistics team to book container space. For Sea Freight, aim to book 3-4 weeks before the ETD. For urgent goods, consider the higher cost of air freight for a portion of your shipment to bridge the gap. Be prepared for premium rates and less predictable schedules during this period.

What are the First Steps to Take When the Factory Reopens?

In the first week after the holiday, reconnect with your supplier's project manager. The goals are:

- Confirm Return to Work: Verify their workforce is back and production has resumed.

- Re-confirm Your Schedule: Get a firm update on the start date for your order's production.

- Check for Issues: Inquire about any potential material shortages or delays that arose during the closure.

This proactive communication demonstrates your engagement and helps surface problems early. It's also the time to send any final reminders or approvals if needed. Patience is crucial, as your contact may be dealing with hundreds of similar inquiries.

How to Secure Shipping and Manage Post-Holiday Delays?

Assume there will be delays. Build a buffer of at least 2-3 extra weeks into your expected delivery date. To secure shipping:

- Book Early: Lock in your freight space as soon as possible, even with an approximate date.

- Consider Alternatives: Explore different ports of departure or arrival that may be less congested.

- Get Guarantees: Ask your forwarder for guaranteed space (GSAs) on vessels, though this may cost more.

- Track Closely: Use container tracking and stay in close contact with both the factory and the forwarder for real-time updates.

Understanding Incoterms 2020 is vital here. If you are on FOB terms, the shipping booking is your responsibility. If your supplier handles DDP, they manage the chaos, but you should still be informed. Having a logistics strategy is as critical as having a tariff and logistics plan for cost control.

How to Build a Resilient Inventory System for Annual Disruptions?

CNY is the ultimate stress test for your inventory management system. A resilient system doesn't just react to CNY; it's designed to absorb such shocks. This involves a combination of data analysis, safety stock calculations, and diversified sourcing strategies.

Implement an Inventory Management Software that tracks sales velocity, lead times, and reorder points. Use this data to calculate your safety stock level—the extra inventory you hold specifically to cover unexpected delays (like a 30-day CNY disruption). The formula often includes your average daily sales multiplied by the extended lead time. Furthermore, consider a multi-supplier strategy for critical items, potentially using suppliers in different regions (e.g., Southeast Asia alongside China) to spread risk, though this adds complexity.

How to Calculate Safety Stock for the CNY Period?

A basic safety stock calculation for CNY accounts for the increase in lead time.

- Determine Normal Lead Time (NLT): e.g., 60 days from order to warehouse.

- Determine CNY-Adjusted Lead Time (CALT): e.g., 90 days due to shutdown and congestion.

- Calculate Lead Time Difference (LTD): CALT - NLT = 30 days.

- Find Average Daily Sales (ADS) for the item.

- Calculate CNY Safety Stock: LTD ADS = 30 (your daily sales).

For example, if you sell 10 units of a hair clip per day, you need an extra 300 units as CNY safety stock, on top of your regular reorder point inventory. This buffer is what prevents a stockout.

Can Diversifying Your Supplier Base Mitigate CNY Risk?

Yes, but it's a strategic decision with trade-offs. Sourcing a portion of your volume from countries like Vietnam, India, or Bangladesh can provide continuity during the CNY period, as their holiday calendars differ. However, diversification introduces new challenges: managing different quality standards, communication styles, and logistics routes. It may not be cost-effective for small volumes or highly custom items where tooling and sample development are major investments. A more accessible first step is to work with a single, large Chinese supplier that has multiple factories or a strong production planning department capable of staggering holidays or managing pre-CNY output very efficiently. The goal is to build resilience, whether through one excellent partner or several.

Conclusion

Managing accessory inventory around Chinese New Year is a definitive test of your supply chain maturity. It requires shifting from a just-in-time mindset to a just-in-case strategy, months in advance. By mastering the critical timeline, placing strategic bulk orders, actively navigating the post-holiday restart, and building calculated safety stock into your systems, you transform a major vulnerability into a predictable, managed event.

The businesses that thrive are those that plan proactively and partner closely with their suppliers. They use CNY not as an excuse for delays, but as an annual reminder to strengthen their operational foundations.

Don't let the holiday shutdown catch you off guard. Partner with a manufacturer that provides clarity and proactive support. At Shanghai Fumao Clothing, we provide our clients with detailed CNY planning calendars, transparent production scheduling, and expert logistics coordination to ensure your inventory flow remains uninterrupted. Contact our Business Director Elaine today at elaine@fumaoclothing.com to create a robust CNY inventory plan for your next season.