For any fashion accessory brand, from a startup selling artisanal scarves to a large distributor shipping thousands of belts and hair ties daily, inventory is both your biggest asset and your biggest risk. Too little stock means lost sales and disappointed customers. Too much stock traps your capital in unsold goods, forcing deep discounts that cut into your profits.

Effective inventory management is a strategic discipline that goes far beyond simple stock counting. It is the systematic process of ordering, storing, tracking, and ultimately selling your accessories Shanghai Fumao Clothing in a way that maximizes sales, minimizes costs, and meets ever-changing customer demand. For accessory sellers, this is uniquely challenging due to factors like diverse SKUs (styles, colors, sizes), rapid trend cycles, and pronounced seasonality.

The solution lies in moving from reactive, manual tracking to a proactive, data-driven system. This involves implementing the right technology, adopting intelligent forecasting methods, and optimizing warehouse operations. Based on industry best practices, this guide provides a comprehensive framework to turn your inventory from a cost center into a competitive advantage.

How to Implement a Technology-Driven Inventory Management System?

The foundation of modern inventory control is the right software system. Relying on spreadsheets or manual records for fashion accessories, with their myriad variations, is a recipe for errors, overselling, and operational chaos. An automated system provides a single source of truth for your stock across all sales channels.

Choosing the right system is critical. The ideal platform should offer real-time synchronization, detailed SKU tracking (for attributes like color, size, material), and robust reporting. For accessory businesses, systems that integrate directly with your e-commerce platform, POS system, and even suppliers are invaluable for creating a seamless workflow from order to delivery.

What Are the Key Types of Management Systems?

Your business size and complexity will determine the best system type:

- Spreadsheet Management: Suitable only for the very beginning stages with a handful of SKUs. It is prone to human error and quickly becomes unmanageable.

- Cloud-Based Inventory Management Software: The standard for most small to medium accessory businesses. Solutions like Shopify POS, Zoho Inventory, or Lightspeed Retail offer affordable, scalable platforms that track inventory in real-time, manage purchase orders, and generate sales reports. They often integrate directly with your online store.

- Enterprise Resource Planning (ERP) & Warehouse Management Systems (WMS): For larger brands with complex supply chains, high SKU counts, or multiple warehouse locations. Systems like Fishbowl or specialized Fashion WMS solutions handle advanced manufacturing tracking, intricate kitting for accessory sets, and highly optimized warehouse logistics. They are a significant investment but deliver dramatic efficiency gains.

How Does Barcode/RFID Technology Transform Accuracy and Speed?

Manual data entry is slow and inaccurate. Implementing barcode scanning is the essential first step toward automation. Every product and its location receives a unique barcode. Scanning items during receiving, picking, packing, and shipping ensures data is instantly and accurately updated in your system, drastically reducing errors.

For high-volume or high-value operations, Radio-Frequency Identification (RFID) is a powerful evolution. Small tags on each item can be read instantly without direct line-of-sight. An RFID portal can count an entire box of scarves in seconds, enabling near-perfect inventory accuracy and allowing for frequent, effortless cycle counts. This technology is a game-changer for preventing loss and speeding up warehouse processes.

How to Forecast Demand and Set Optimal Stock Levels?

Inventory management is not about what you have sold, but about what you will sell. Accurate demand forecasting is what separates profitable brands from those burdened by dead stock. For fashion accessories, this is particularly complex due to trends, seasonality (e.g., winter hats vs. summer sunglasses), and the influence of social media.

A data-driven forecasting strategy uses historical sales data as its foundation but layers in market intelligence and real-time analytics to predict future needs. The goal is to establish dynamic safety stock levels and reorder points for each SKU, ensuring you never miss a sale but also don't overcommit capital.

What Are the Core Forecasting Methods for Accessories?

Effective forecasting is multi-faceted:

- Historical Sales Analysis: This is your baseline. Analyze what sold last year, last season, and during past promotions. Look for patterns in colors, materials, and styles.

- ABC Analysis for Prioritization: Not all inventory is equal. Classify your SKUs into three categories:

- A-Items: High-value, top-selling accessories (e.g., your signature leather belt). Manage these closely with frequent reviews.

- B-Items: Steady sellers with moderate turnover.

- C-Items: Low-cost, slow-moving items (e.g., a specific color of basic hair tie). Order these in smaller quantities or bundle them.

This method ensures you focus time and capital on the products that drive your business.

- Integrating Market Intelligence: Data shouldn't exist in a vacuum. Incorporate insights from trend reports, social media sentiment, and competitor analysis to adjust your forecasts for upcoming seasons. Is there a sudden surge in popularity for pearl hair clips? Your forecast should reflect that.

How Do You Calculate and Automate Replenishment?

Once you have a forecast, you can set intelligent inventory parameters:

- Safety Stock: This is your buffer stock to prevent stockouts caused by unexpected demand spikes or supplier delays. The formula often considers your average daily sales and lead time variability.

- Reorder Point (ROP): The inventory level at which a new purchase order must be placed. ROP = (Average Daily Sales x Lead Time in Days) + Safety Stock.

Modern inventory software can automate this entire process. You set the rules, and the system monitors stock levels, automatically generating purchase orders or sending low-stock alerts when a product hits its ROP. This shifts your role from firefighter to strategic planner.

What Are the Best Practices for Warehouse and Process Optimization?

Efficient inventory management extends beyond the software screen into the physical realm of your warehouse or stockroom. An disorganized storage space leads to lost products, slow order fulfillment, and frustrated employees. Optimizing your warehouse layout and processes is crucial for scalability and customer satisfaction.

The principles of an efficient accessory warehouse are clear organization, logical workflow, and space maximization. Every minute saved in picking and packing an order directly improves your bottom line and allows you to handle higher sales volumes without proportional increases in overhead.

How Should You Organize Your Storage Space?

Follow these guidelines to create an efficient layout:

- Implement a Logical Layout: Design a workflow that follows the order fulfillment path: Receiving → Inspection & Labeling → Storage → Picking → Packing → Shipping. Minimize backtracking.

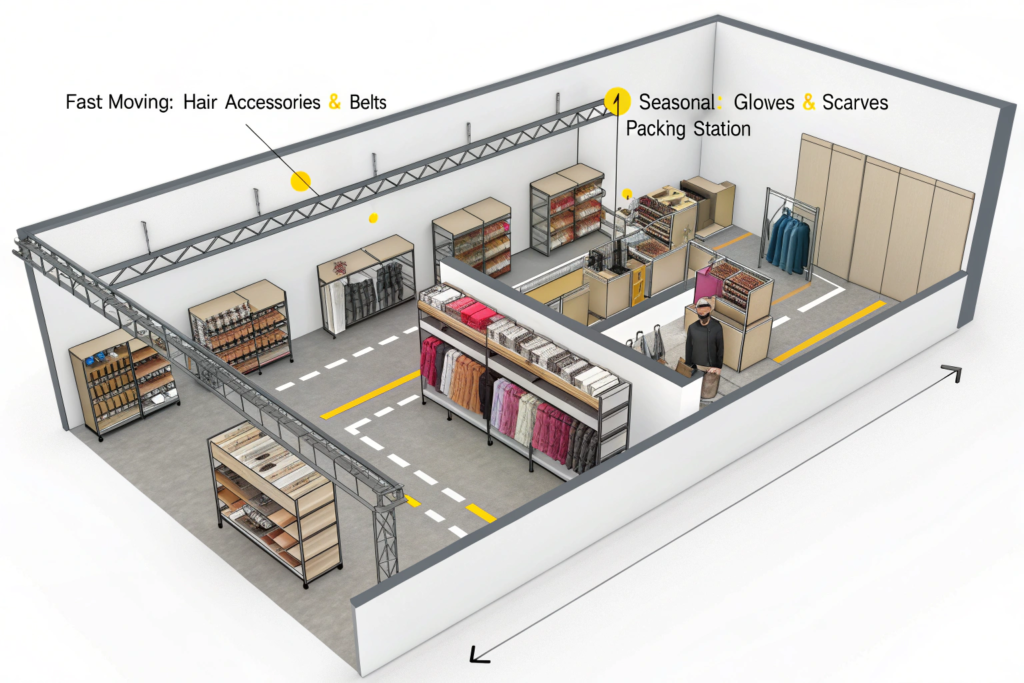

- Adopt the ABC Method Physically: Store your A-Items (fastest sellers) closest to the packing station to minimize pickers' travel time. Slower-moving C-Items can be placed in higher or farther locations.

- Use Clear Labeling and Binning: Every shelf, bin, and box should have a unique location code (e.g., A-12-05). Your inventory system should track which SKU is in which bin. Combined with barcode scanning, this allows for instantaneous location and picking.

- Optimize for Accessory Types: Consider specific storage needs. Delicate silk scarves might need hanging or flat boxes, while durable resin hair clips can be stored in bulk bins. Jewelry may require secure, divided trays.

Why Are Regular Audits and Cycle Counting Critical?

Even with the best systems, discrepancies occur. Regular inventory audits are essential to ensure your system records match physical stock.

- Traditional Full Physical Count: Stopping all operations to count everything is disruptive but may be done annually.

- Cycle Counting: A more efficient, continuous method. You count a small subset of inventory (e.g., all A-Items or all items in a specific aisle) every day, week, or month. Over time, you count everything without major downtime. This helps identify and investigate causes of shrinkage (theft, damage, administrative errors) promptly.

Automated systems with barcode scanners make cycle counting fast and accurate, turning a dreaded chore into a routine quality control check.

How to Develop a Strategic Purchasing and Supplier Relationship Framework?

Your inventory performance is intrinsically linked to your supply chain. Erratic purchasing leads to stock imbalances, while poor supplier relationships cause delays and quality issues. Developing a strategic framework for procurement is the final pillar of robust inventory management.

This involves moving from ad-hoc ordering to a planned, collaborative process with your manufacturers. For an accessory brand, this might mean working closely with your key suppliers to plan seasonal collections, negotiate flexible minimum order quantities (MOQs), and ensure timely production.

What Makes an Effective Purchasing Strategy?

Your purchasing should be a direct output of your sales forecast and inventory parameters.

- Data-Driven Order Quantities: Use your forecasted demand, current stock levels, and lead times to calculate precise order quantities. Avoid the temptation to over-order based on a "gut feeling" about a new trend.

- Consolidate Orders: Where possible, consolidate multiple product lines into fewer, larger purchase orders. This can often secure better pricing from suppliers and simplify logistics.

- Negotiate Flexible Terms: Work with suppliers to negotiate terms that benefit your cash flow and inventory health. This could include smaller, more frequent shipments (Just-in-Time principles), consignment inventory, or favorable return policies for slow-moving items.

How Do Strong Supplier Partnerships Mitigate Risk?

Treat your suppliers as strategic partners, not just vendors.

- Clear Communication: Share your sales forecasts and inventory plans with key suppliers. This helps them prepare their raw materials and production capacity, leading to more reliable lead times for you.

- Collaborative Problem-Solving: When issues arise—a delayed dye lot, a quality problem—work together to find a solution. A strong relationship means a supplier is more likely to go the extra mile to prioritize your order or help you resolve a stock crisis.

- Diversify When Necessary: For critical components or best-selling items, consider developing a relationship with a secondary supplier. This mitigates the risk of being completely stalled by a disruption at your primary partner's facility.

Conclusion

Mastering inventory management for fashion accessories is a continuous journey of refinement that balances art with science. It requires implementing the right technological foundation—a cloud-based system enhanced by barcode or RFID tracking—to achieve real-time visibility and accuracy. This system must be fueled by intelligent, data-driven forecasting that respects the seasonality and trend-driven nature of accessories, using tools like ABC analysis to prioritize focus. Furthermore, efficiency must extend into the physical realm through an optimized warehouse layout and disciplined cycle counting practices. Finally, all of this is underpinned by strategic purchasing and collaborative supplier relationships that make your supply chain resilient and responsive.

By adopting this holistic framework, you transform inventory from a passive collection of goods into an active, dynamic asset. You will reduce costs associated with overstock and stockouts, improve cash flow, increase operational efficiency, and, most importantly, ensure that your customers can always find the accessory they desire. This leads to stronger brand loyalty, healthier profit margins, and a scalable business model ready for growth.

If you are building or scaling your accessory brand and seek a manufacturing partner who understands the importance of quality, consistency, and strategic collaboration in inventory success, we are here to help. At Shanghai Fumao Clothing, we partner with brands to not only produce exceptional accessories but also to support smart supply chain planning. For a conversation about producing your next collection with a partner who values your operational success, please contact our Business Director, Elaine, at elaine@fumaoclothing.com.