Are you holding a perfect accessory sample but terrified that a factory will ruin it in mass production? Do you fear receiving a bulk order that's a poor imitation—wrong colors, flimsy materials, misaligned details? You're facing the critical leap from prototype to production, where countless good designs fail. Finding a factory that can execute perfect replication is less about searching and more about systematic vetting and communication.

The ability to perfectly replicate a sample is the hallmark of a professional factory with disciplined processes. It requires more than just machinery; it requires technical literacy, rigorous quality control, and a culture of precision. The right factory treats your sample not as a suggestion, but as the absolute master blueprint. Your job is to find the partner whose systems guarantee fidelity to that blueprint.

This guide provides a step-by-step methodology. We'll cover how to prepare the definitive "master sample package," identify factories with the specific technical competencies for your item, conduct the ultimate replication test during sampling, and establish the quality protocols that lock in perfection for the entire production run. Let's turn your one perfect sample into ten thousand perfect products.

How to Prepare the "Master Sample Package" for Your Factory?

Your sample is not enough. To demand perfect replication, you must provide a complete, unambiguous set of instructions. This "Master Sample Package" is your legal and technical contract with the factory. It removes guesswork and sets the standard for acceptance.

The package must contain three core elements:

-

The Physical "Golden Sample": This is the sample you approve for production. It should be in perfect condition. Mark it indelibly (e.g., with a permanent marker or tag) as "MASTER SAMPLE - APPROVED FOR PRODUCTION" and sign/date it. This sample will be used for side-by-side comparison during Pre-Shipment Inspection (PSI).

-

The Complete Tech Pack: This is the digital blueprint. It must include:

- Detailed CAD Drawings: Orthographic views with every critical dimension (in mm).

- Bill of Materials (BOM): A line-item list of every single component, including part numbers, material specifications (e.g., "Brass, C2600, 0.8mm thick"), and approved supplier sources if you have them.

- Color Standards: Physical Pantone swatches or lab-dip approvals for all colors (fabric, metal, paint). Include photos of the master sample under different lighting.

- Finishing Specifications: Describe surface textures (brushed, polished, matte), plating thickness (e.g., "2µm gold PVD over 5µm Ni"), and any special treatments.

- Step-by-Step Assembly Instructions: Diagrams or photos showing the assembly sequence.

-

The Quality Benchmark Document: Specify the Acceptable Quality Level (AQL) you will use for inspection (e.g., ANSI/ASQ Z1.4, Level II, AQL 1.0 for critical defects). Include close-up photos of the master sample highlighting critical areas for inspection.

Why is a Detailed BOM More Important Than a Photo?

A photo shows what it should look like. A Bill of Materials defines what it is made of. A factory can make something that looks similar from cheaper materials. Your BOM is your defense. For example, instead of "gold metal clip," specify:

- Base Metal: Brass Alloy C2600, thickness 0.8mm

- Plating Process: PVD (Physical Vapor Deposition)

- Plating Stack: 5µm Nickel barrier + 2µm 18k Gold tone

- Plating Adhesion Standard: Pass ASTM B571 cross-cut test

This level of detail, similar to what's needed for durable belt buckles, forces the factory to source correctly or formally request substitutions, which you can then approve or reject.

How to Document Colors and Finishes to Prevent Mismatch?

Color is highly subjective. Eliminate subjectivity:

- For Fabrics/Dyes: Provide the Pantone Textile Color (TCX) number and an approved lab-dip (a small fabric swatch dyed to your spec). The factory must match the lab-dip, not a photo on your screen.

- For Metal/Plastics: Provide a physical color standard (a Pantone plastic chip or a painted metal chip) and specify the finish (e.g., "matte," "high-gloss polish").

- Take Reference Photos: Photograph the master sample next to the color standard under daylight (D65) lighting. Include these photos in the tech pack.

State: "Color matching must be approved against the provided physical Pantone swatch #XXX under D65 light." This formalizes the approval process.

How to Identify Factories with True Replication Capabilities?

Not all factories are created equal. You need to find those with a proven track record in your specific accessory category and the in-house controls to ensure consistency. Look beyond glossy websites to operational substance.

Search for factories that emphasize OEM/ODM services and sample development in their marketing. Use precise search terms: "accessory sample replication factory," "OEM hair accessory manufacturer," or "sample-to-production specialist." During initial contact, immediately ask about their process for handling a client-provided sample. A competent factory will ask for your tech pack or a detailed description to provide a preliminary assessment.

Key capabilities to verify:

- In-House Tooling & Mold Making: For items requiring custom molds (e.g., plastic clips, metal castings), a factory with its own mold shop has more control over precision and faster iteration.

- Dedicated Sample Room: A separate department for prototyping indicates a structured R&D process.

- Quality Control Labs: Look for equipment like calipers, color spectrophotometers, cross-cut testers, and salt spray test chambers. These tools enable objective measurement against your specs.

A partner like Shanghai Fumao Clothing invests in these capabilities to serve brands that demand precision.

What Factory Audits or Visits Are Essential for Verification?

A virtual or physical audit is non-negotiable. Request a live video tour focused on:

- The Sample Room: Are samples organized? Are technicians working from detailed drawings?

- The Production Floor: Is it clean and organized? Is there a clear workflow?

- The QC Station: Do inspectors have measurement tools, defect samples, and checklists? Ask to see a recent inspection report.

- Material Storage: Are raw materials labeled and stored properly?

Ask for their standard operating procedure (SOP) for sample replication and production handoff. A factory with documented processes is more reliable than one run on ad-hoc decisions. This scrutiny is as important as vetting a supplier for partnership.

Should You Choose a Specialist or a Generalist Factory?

Always choose a specialist for replication. A factory that makes a wide range of unrelated products (e.g., electronics and hair clips) is a red flag. You want a factory whose core business is your product category (e.g., metal accessories, knitted hats, leather goods). Specialists have:

- Dedicated Equipment: The right machines for your materials.

- Experienced Technicians: Deep knowledge of the specific processes (e.g., plating for metal, stitching for leather).

- Established Supply Chains: Relationships with material suppliers who meet the quality standards for that niche.

A generalist may be cheaper but is far more likely to cut corners or misunderstand critical details.

How to Use the Sampling Phase as the Ultimate Replication Test?

The sampling phase is your proving ground. Do not rush it. A factory that cannot replicate perfectly in the sampling stage will certainly fail in mass production. Treat this as a paid test of their capabilities.

Follow a strict sampling protocol:

- Stage 1: Development Sample (Proto): The factory uses your tech pack to create a first sample. This tests their understanding of the design and materials. Expect and require revisions.

- Stage 2: Pre-Production (PP) Sample: This sample must be made with the exact mass-production materials and methods. This is the sample you evaluate against your master sample. Be ruthless in your evaluation.

- Stage 3: Production (Top) Sample: Taken from the first batch of mass production. This verifies they have maintained the standard from the PP sample at scale.

At each stage, conduct a side-by-side comparison with your master sample using the criteria from your Quality Benchmark Document.

What Specific Checks Form a Side-by-Sample Comparison?

Create a checklist and physically compare the PP sample to the Master:

- Dimensional Accuracy: Use digital calipers to measure 5-10 key dimensions. Are they within a 0.5mm tolerance?

- Weight: Does it weigh the same (a sign of correct material density)?

- Color & Finish: Compare under the same light. Is the color match 95%+? Is the surface finish identical (gloss level, texture)?

- Functionality: Test any moving parts (clasps, hinges) 50 times. Do they perform identically?

- Material Hand Feel: Is the fabric, metal, or plastic the same stiffness, softness, and temperature?

- Packaging & Labeling: Are all tags, labels, and packaging components correct?

Document any deviations with photos and clear notes. This meticulous process is the core of effective sample evaluation.

How Many Sample Rounds Are Reasonable to Demand Perfection?

Budget for and expect 2-4 sample rounds to achieve perfection. The process should look like this:

- Round 1: 60-70% match. Many corrections needed.

- Round 2: 85-90% match. Minor tweaks on color, finish, or dimensions.

- Round 3: 95-100% match. Final approval.

- Round 4 (if needed): Confirmation sample after corrections.

Each round should be paid for, but view it as an investment. The cost of perfecting the sample is minuscule compared to the cost of rejecting a 10,000-piece shipment. A factory that resists multiple sample rounds is not committed to quality.

How to Lock In Perfection for the Full Production Run?

Approving the perfect PP sample is only half the battle. You must ensure that every unit in the production run matches it. This requires contractual agreements and active monitoring.

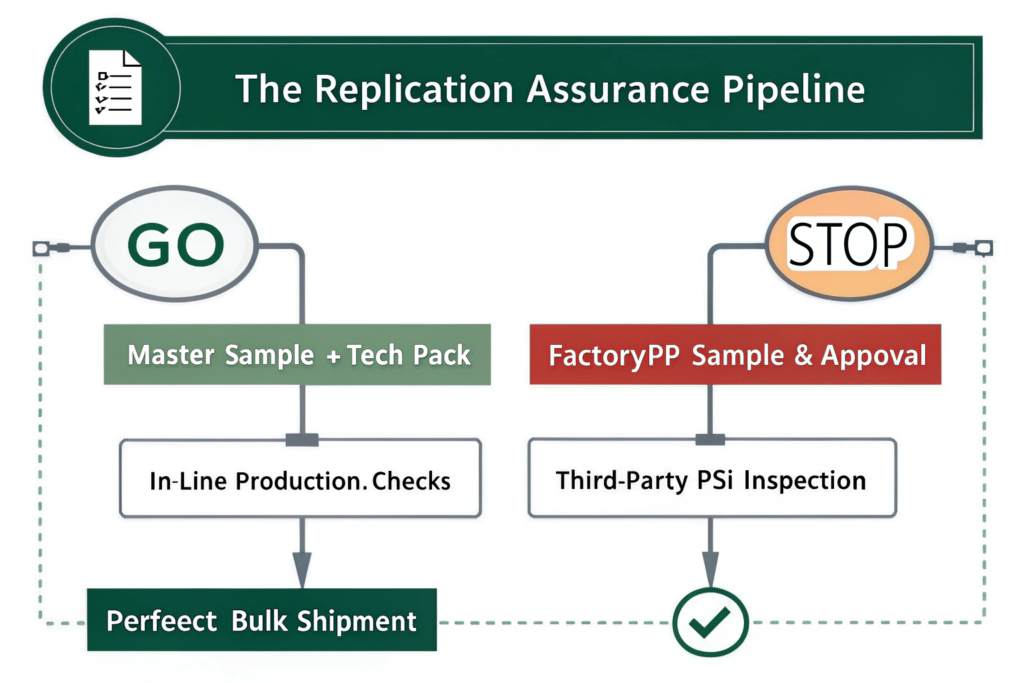

Implement a Four-Eye Production Control System:

-

Pre-Production Meeting: Before mass production starts, have a meeting (or detailed email) with the factory's production and QC managers. Review the approved PP sample and the tech pack. Confirm the production schedule and key inspection points.

-

In-Process Quality Checks (IPQC): Require the factory to perform and document checks at critical stages (e.g., after cutting, after plating, after assembly). Request photos or videos of these checks, especially of the first articles off the line.

-

Third-Party Pre-Shipment Inspection (PSI): This is your final gatekeeper. Hire a reputable inspection company (like SGS, QIMA, or Asia Inspection) to perform an AQL inspection on the finished goods. The inspector will use your approved PP sample as the reference standard. The inspection report is your objective evidence to accept or reject the shipment.

-

Clear Contractual Terms: Your purchase order or contract should state: "Goods must match the approved PP sample in all respects, as verified by a passing third-party PSI report. Non-conforming goods will be rejected at the factory's expense."

What Should Be in Your PSI Inspection Checklist?

Your hired inspector should have a custom checklist that includes:

- Workmanship & Construction: Stitching, glue, soldering, assembly.

- Dimensions & Weight: Random verification of key specs.

- Function & Safety: All moving parts work; no sharp edges.

- Color, Logo & Appearance: Visual match to PP sample.

- Packing & Labeling: Correct as per instructions.

- Quantity & assortment.

The AQL standard determines how many pieces are checked and the allowable defect count. For critical replication items, use a tight AQL like Level II, AQL 1.0 for major defects, AQL 4.0 for minors.

How to Handle Material Substitutions or "Equivalent" Offers?

Factories will often propose "equivalent" materials to save cost or due to availability. Your response must be firm: "Any deviation from the approved BOM or PP sample requires our written approval prior to implementation." If they propose a substitute, demand a comparative sample showing the old and new material side-by-side, along with test data if applicable (e.g., strength test for a different plastic). Only approve if it meets or exceeds the original spec. This protects you from the #1 cause of failed replication: unauthorized material changes.

Conclusion

Finding a factory that replicates perfectly is a systematic exercise in due diligence, precise communication, and rigorous validation. By creating an unassailable Master Sample Package, vetting factories for technical depth and process discipline, using the sampling phase as a paid replication test, and enforcing quality through in-process checks and third-party inspections, you transform the high-risk act of production into a predictable, controlled outcome.

This approach ensures your vision is preserved at scale, protecting your brand's reputation and your bottom line. It turns manufacturing from a source of anxiety into a pillar of your brand's strength.

Demanding perfection in replication? Partner with a factory built for it. At Shanghai Fumao Clothing, our process is engineered for fidelity: from dedicated sample rooms and in-house tooling to rigorous IPQC and support for third-party inspections. Contact our Business Director Elaine at elaine@fumaoclothing.com to see how we turn your one perfect sample into ten thousand.