You're designing or sourcing knitted hats, and the brief is clear: they must be cozy and warm for winter, but no one wants a sweaty, clammy scalp. It seems like a contradiction—how can a hat trap heat without also trapping moisture? Getting this balance wrong leads to customer dissatisfaction, returns, and products that fail in their core function. How do you engineer a knitted hat to master this delicate equilibrium?

The key to achieving warmth with breathability in a knitted hat lies in the strategic selection of fibers, the intelligent construction of the knit, and the thoughtful integration of design features. It's not about finding a single magic material, but about creating a system where insulating air is trapped by warm fibers while moisture vapor is actively transported away from the skin. This involves using natural or technical yarn blends, employing specific stitch patterns that create air pockets, and designing with ventilation in mind. For a manufacturer like us at Shanghai Fumao Clothing, this is a technical challenge we solve daily, balancing aesthetic design with functional performance to create accessories that are both stylish and genuinely comfortable for all-day wear.

This balance is what separates a basic commodity hat from a performance-oriented accessory that customers will love and repurchase. Let's unravel the techniques that make it possible.

What is the Science Behind Warmth and Breathability?

Before choosing yarns or patterns, it's essential to understand the basic principles at play. Warmth and breathability are governed by different physical properties, and a successful hat manages both simultaneously.

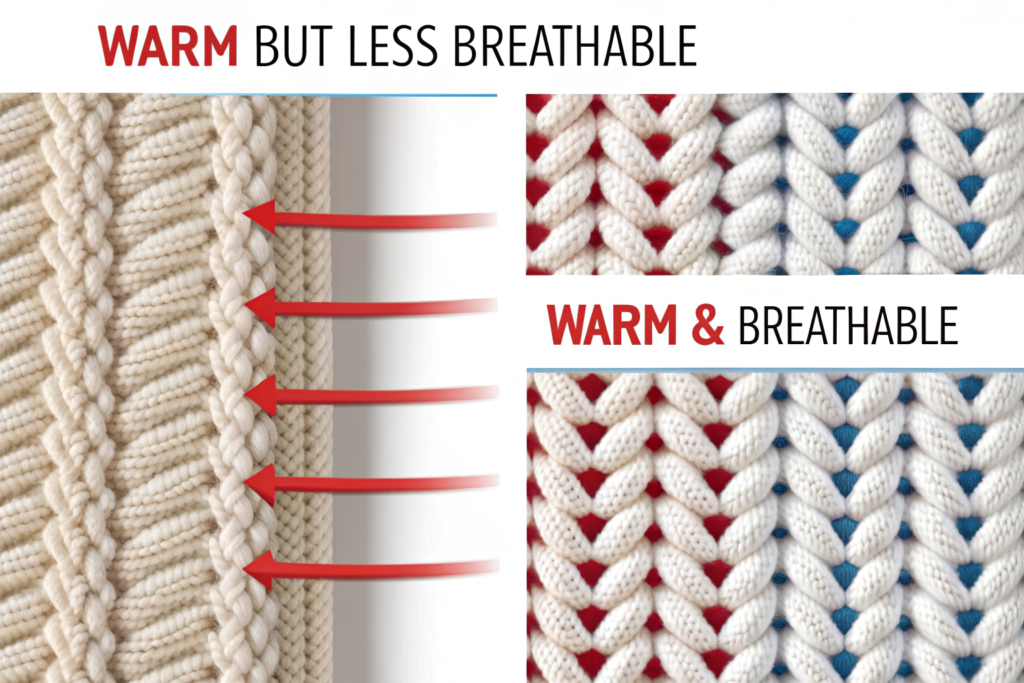

Warmth (Insulation) is primarily about trapping air. Still air is an excellent insulator. The fibers in yarn create a lofty structure that holds pockets of air close to the body, preventing body heat from escaping. The more stable air pockets a fabric can create and hold, the warmer it is. Breathability (Moisture Management) is about releasing vapor. When you're active, your body releases moisture as vapor (sweat). A breathable fabric allows this water vapor to pass through its structure to the outside environment, preventing it from condensing on your skin or within the fabric, which would lead to dampness and rapid heat loss. The challenge is that a very dense, tight knit might trap air well for warmth but block vapor escape. Conversely, a very loose, open knit might be breathable but not warm. The solution lies in choosing materials and structures that excel at wicking (pulling moisture away from the skin) and venting (allowing vapor to evaporate). This is a core concept in performance textile engineering.

How Do Fibers Trap Air and Manage Moisture?

Different fibers have inherent properties:

- Wool (especially Merino): The king of natural performance fibers. Its crimped structure creates excellent loft for trapping air. It is also hygroscopic, meaning it can absorb a significant amount of moisture vapor (up to 30% of its weight) without feeling wet, and it releases this vapor into the air. This makes it both warm and breathable.

- Acrylic: A synthetic fiber that can be engineered to mimic wool's loft. It is warm and lightweight but is hydrophobic, meaning it does not absorb moisture. It relies on construction (like open knits) to allow vapor to pass through, or it must be blended with wicking fibers.

- Polyester: Often used in technical performance blends. It can be engineered into fine filaments that excel at wicking—pulling liquid moisture away from the skin to the fabric's surface where it can evaporate.

- Cashmere & Alpaca: Incredibly soft and warm due to fine, hollow fibers that trap air, but they can be less breathable than wool if knit densely and may require blending.

The goal is to combine fibers so their strengths complement each other: e.g., wool for warmth and vapor absorption, with a small percentage of polyester for enhanced wicking.

What is the Role of Fabric "Loft"?

Loft refers to the thickness and airiness of a knitted fabric. A high-loft fabric has more trapped air per square inch, making it warmer without necessarily being heavier or less breathable. Loft is created by:

- Fiber Crimp: Naturally crimped fibers like wool spring apart, creating space.

- Yarn Construction: Bulky, thick-and-thin, or brushed yarns increase volume.

- Stitch Pattern: Certain stitches (like cables or popcorn stitches) physically push the fabric outwards.

A hat with good loft will feel light and puffy, not flat and dense. Maintaining this loft after washing is also crucial, which relates to fiber quality and blend.

How to Choose the Right Yarn Blend?

The single most important decision for a hat's performance is the yarn. A pure fiber is rarely the answer; modern blends are engineered to optimize both warmth and breathability.

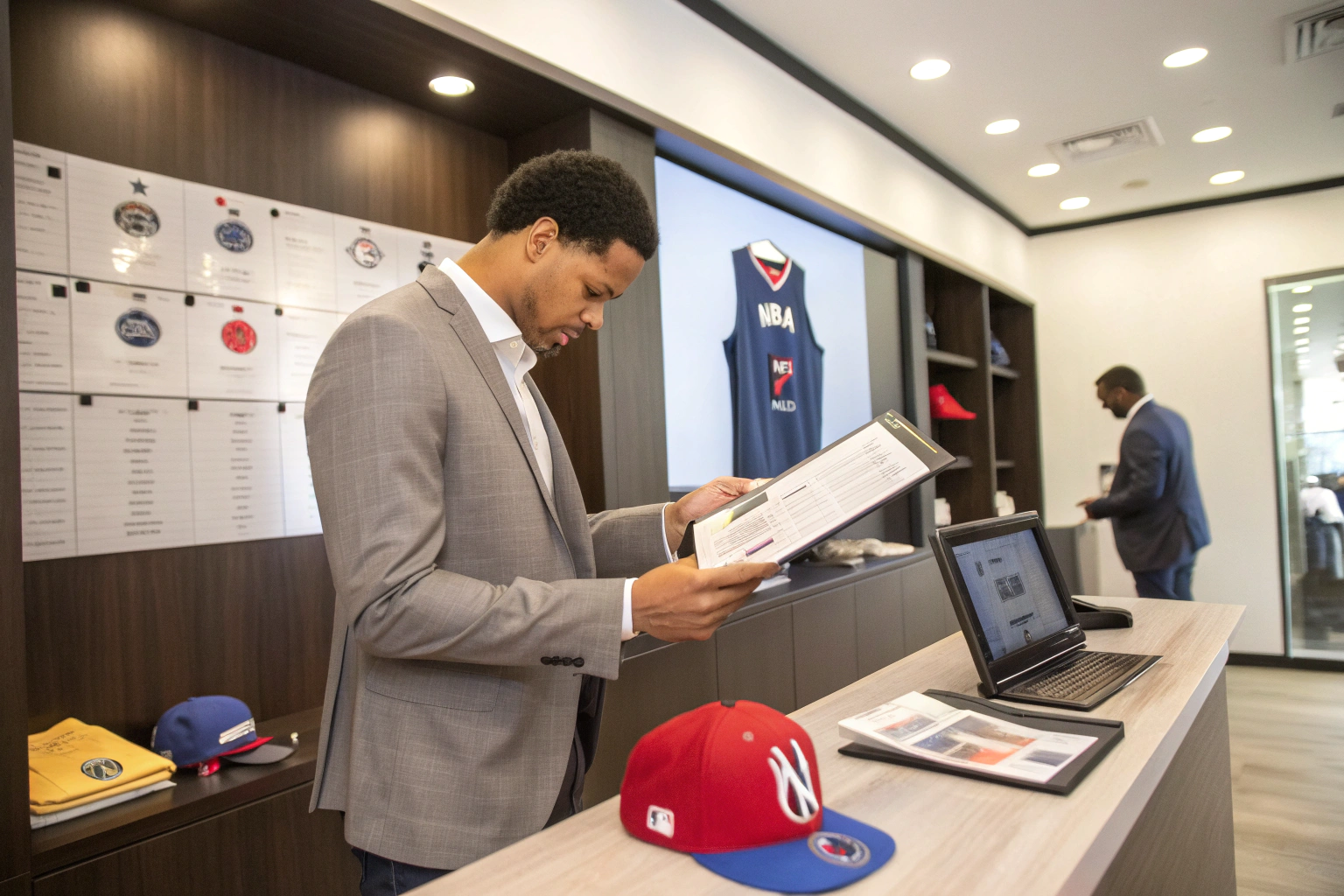

Select yarns based on the intended use. For high-activity winter sports (skiing, running), prioritize moisture-wicking and breathability. A blend like Merino Wool (50-70%) / Polyester (30-50%) is ideal. The Merino provides warmth and vapor absorption, while the polyester enhances wicking, durability, and speeds drying. For casual everyday winter wear, where extreme breathability is less critical but comfort is key, a Merino Wool / Acrylic blend is excellent. It offers great warmth, softness, and cost-effectiveness, with enough breathability for typical use. For a luxury feel, Cashmere blended with Silk or fine Merino adds breathability and strength to the ultra-warm cashmere. Always request yarn specifications from your supplier, including fiber percentage and yarn weight. At Shanghai Fumao Clothing, we source and test various blends to recommend the optimal one for our clients' specific product goals and price points, a service detailed in our material sourcing capabilities.

What are the Pros and Cons of Common Knit Hat Fibers?

Here’s a quick-reference table:

| Fiber | Warmth | Breathability/Moisture Management | Key Trait | Best For |

|---|---|---|---|---|

| Merino Wool | High (excellent loft) | Excellent (absorbs vapor) | Natural, temperature-regulating | All-purpose, performance, sensitive skin |

| Acrylic | High (good loft) | Moderate (depends on knit) | Lightweight, cost-effective, colorfast | Casual fashion, budget-friendly lines |

| Polyester | Moderate | Excellent (superior wicking) | Durable, quick-drying, strong | Performance blends, base layers |

| Cashmere | Very High | Low-Moderate (can overheat) | Ultra-soft, luxurious feel | Luxury, dressy, low-activity wear |

| Cotton | Low (when wet) | High (absorbs liquid) | Soft, natural, but holds moisture | Lightweight beanies, not for wet cold |

Why are Blends Superior to Pure Fibers for This Balance?

Blends allow you to "program" the yarn's behavior. For example:

- Pure acrylic might be warm but can feel clammy during activity because sweat condenses on it.

- Adding 20-30% wool to an acrylic blend introduces hygroscopic properties, improving vapor management.

- Adding 10-15% nylon or polyester to a wool blend increases tensile strength and reduces pilling, enhancing durability without sacrificing much warmth.

A common and effective blend for a balanced winter hat is 80% Acrylic / 20% Wool. It offers great warmth, improved breathability over pure acrylic, softness, and an accessible price point for wholesale or retail.

What Knitting Techniques Enhance Breathability?

The construction of the hat is as important as the yarn. The stitch pattern and knitting technique directly control how much air and moisture can move through the fabric.

Employ textured stitch patterns that create a 3D structure. Patterns like ribbing (1x1 or 2x2), cables, basketweave, or seed stitch naturally create ridges and valleys. These textures increase the surface area of the fabric and create tiny channels for air and vapor to circulate. Ribbing at the cuff is essential not just for fit, but because its elastic, raised structure is inherently more breathable than a plain, tight knit. For the body of the hat, consider alternating panels of texture. Also, the tightness of the knit (gauge) matters. A slightly looser gauge (fewer stitches per inch) creates a more open fabric that breathes better, while still providing loft for warmth if the yarn is right. Modern knitting machines, like seamless circular knit machines, can produce these complex textures efficiently and consistently, which is a capability we leverage in our production for clients seeking both style and function.

How Do Specific Stitch Patterns Create Air Flow?

Different stitches manipulate the fabric in distinct ways:

- Rib Stitch (K1, P1): The alternation of knit and purl stitches makes the fabric draw in vertically but stretch horizontally. This creates vertical columns of raised knit stitches with slight gaps between them, perfect for subtle air circulation.

- Cable Stitches: These cross stitches over each other, physically pushing the fabric outward. This creates a thick, warm fabric, but the raised cable itself and the recessed background create a landscape that allows for more air movement across the surface than a flat fabric of the same thickness.

- Linen Stitch or Mesh Patterns: These incorporate deliberate, small gaps or openwork into the fabric. This is extremely breathable and good for mild weather, but for warmth, they must be used sparingly or in combination with a dense lining.

The key is to use these textures over most of the hat's surface, not just as a decorative band.

Can You Add Strategic Ventilation Panels?

Yes, this is an advanced but highly effective technique, often seen in performance ski hats. This involves knitting small, discreet mesh panels in areas of high heat and moisture output, typically:

- On the sides, above the ears: Where heat builds up.

- At the crown/top of the head: Where heat rises and accumulates.

These panels can be made with a more open stitch pattern or even with a different, highly wicking yarn. They provide targeted breathability without compromising overall warmth. Designing such features requires precise pattern engineering and is a mark of a technically sophisticated manufacturer, aligning with principles of activewear and performance apparel design.

What Design Features Can Make a Hat More Breathable?

Beyond the knit itself, the overall design and finishing of the hat play a crucial role in managing heat and moisture.

Consider these design elements:

- A Slouch or Loose Fit: A hat that is not skin-tight allows for a microclimate of air between the head and the fabric. This air layer warms up and acts as an additional insulator, but also allows moisture vapor to dissipate more easily before it condenses. A very tight beanie compresses the knit's loft (reducing warmth) and presses directly against the skin (reducing breathability).

- A Fold-Up Brim: A double-layer brim provides extra warmth at the forehead and ears, but the ability to fold it up (creating a single layer) offers instant ventilation and temperature regulation when needed.

- Moisture-Wicking Sweatband: Integrating a thin, specialized fleece or terry cloth sweatband on the inside of the forehead area can dramatically improve comfort. This band, often made of a polyester blend, wicks sweat away from the skin before it can saturate the main hat fabric. This is a common and valued feature in high-performance hats.

- Pom-Poms or Top Knots: While decorative, a pom-pom can actually aid breathability by preventing the crown of the hat from sitting completely flat against the head, creating a small air pocket at the very top.

How Does Fit Impact Thermal Regulation?

Fit is critical. The perfect winter hat should feel snug but not constricting. It should stay on during movement without leaving a deep red line on the forehead. A proper fit ensures:

- The insulating loft of the knit is not compressed.

- Blood circulation is not restricted (which itself causes coldness).

- There is minimal gap for cold air to enter at the bottom, but enough room for air exchange at the top.

Providing a size chart (S/M, M/L) rather than just "one-size-fits-most" can help customers achieve a better fit, leading to better perceived performance.

What is the Benefit of a Integrated Sweatband?

An integrated sweatband is a game-changer for active use. Its benefits are:

- Direct Moisture Management: It intercepts liquid sweat at the source (the brow line).

- Protects Main Fabric: It prevents salt and oil from sweat from degrading and staining the primary yarn (especially important for natural fibers like wool).

- Comfort: The band is often made from a soft, brushed material that feels pleasant against the skin.

- Durability: It can take the brunt of wear and tear, and can sometimes be replaced.

For brands targeting sports or outdoor enthusiasts, this feature is a significant selling point and a mark of quality. It reflects an understanding of end-user needs in functional apparel.

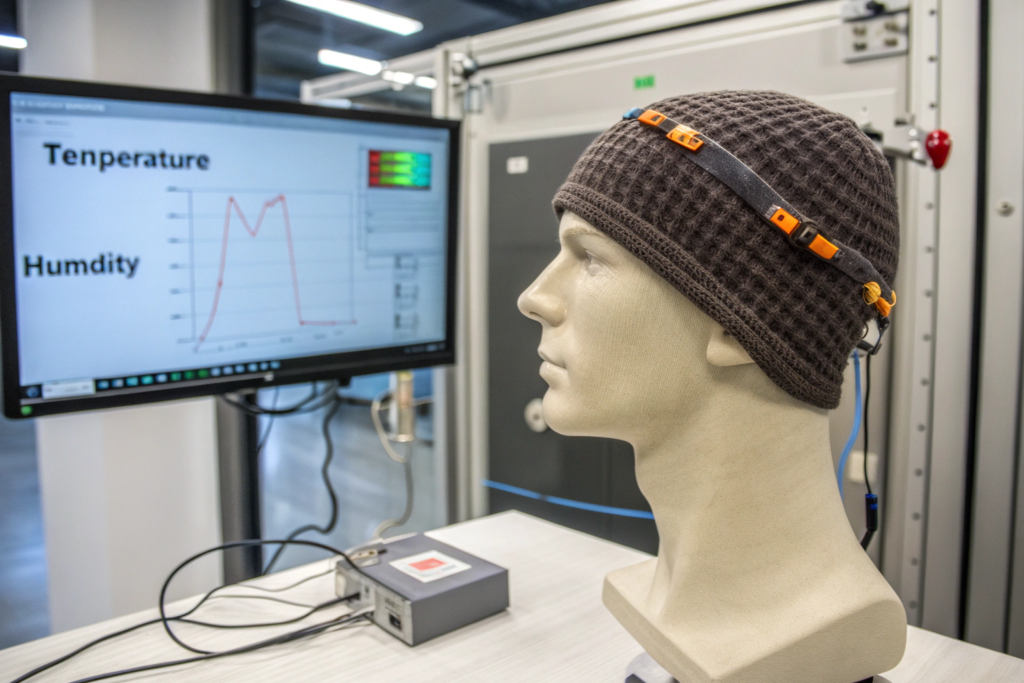

How to Test and Validate Your Hat's Performance?

Before going into bulk production, you must verify that your design choices actually work. Subjective feeling is important, but objective tests provide confidence and quality assurance.

Implement a multi-stage testing protocol:

- Lab Testing (if possible): For large orders or technical products, send yarn or fabric swatches to a lab for tests like Moisture Vapor Transmission Rate (MVTR) and Thermal Insulation (Clo value). This provides scientific data.

- Wear Trials: Have a diverse group of people wear prototype hats in real-world conditions—during a cold-weather walk, while running errands, during low-intensity exercise. Gather feedback on warmth, itchiness, moisture buildup, and fit.

- Wash and Durability Testing: Wash the hat according to care instructions 5-10 times. Does it lose its loft (flatten)? Does the shape distort? Does the color bleed? A hat that loses its puffiness after one wash has failed.

- Compare to a Benchmark: Test your prototype against a leading commercial hat you know performs well. How does it compare in weight, warmth, and perceived breathability?

At Shanghai Fumao Clothing, our quality control process includes wear testing and rigorous wash testing to ensure the products we deliver maintain their functional properties over time, safeguarding our clients' brand reputation. This aligns with industry standards for textile quality and performance testing.

What Simple Tests Can You Do on a Sample?

Even without a lab, you can conduct insightful tests:

- The Breath Test: Hold a single layer of the knit fabric over your mouth and exhale. You should feel your breath pass through with moderate resistance. If no air passes, it's not breathable. If it passes too easily, it may not be warm.

- The Loft Test: Squeeze the hat in your hand and release. How quickly does it spring back to its original shape? Fast recovery indicates good loft retention.

- The Moisture Test: Place a drop of water on the inside of the fabric. For a wicking blend, it should spread along the fibers rather than beading up. For a wool-blend, it should be absorbed slowly without soaking through immediately.

Why is Post-Wash Performance Critical?

A hat must perform after multiple washes. Acrylic and polyester blends generally hold their shape and loft well. Wool and wool blends require more care (cold water, lay flat to dry) but should not felt or shrink dramatically if the yarn is of good quality and properly treated. Always provide clear care labels. A hat that becomes misshapen or flat after its first wash is a product failure in the eyes of the consumer and will generate negative reviews, impacting future sales based on online reputation management principles.

Conclusion

Creating a knitted hat that is both warm and breathable is an achievable exercise in balanced design and material science. It requires moving beyond aesthetic considerations to functionally engineer the product through smart fiber blending, thoughtful stitch patterning, and user-centric design features like fit and sweatbands. The goal is to create a microclimate around the head that retains heat while efficiently transporting moisture away.

For brands, nail ing this balance means delivering superior comfort, which translates into positive customer experiences, repeat purchases, and strong word-of-mouth. It elevates a simple accessory into a performance product that customers rely on and trust.

If you are looking to develop a line of knitted hats that master this essential balance of warmth and breathability, our technical design and production team is ready to assist. We specialize in optimizing blends, patterns, and construction for functional accessories. For a consultation, please contact our Business Director, Elaine. Let's create hats that people love to wear, all day, in any winter activity. Reach Elaine at: elaine@fumaoclothing.com.