You have a fantastic design for a new knitted beanie. You know the exact fit, the perfect yarn color, and the unique cuff detail that will make it a bestseller. But now you face a critical challenge: how do you communicate this precise vision to a factory halfway across the world? You're worried that without a clear, professional document, your idea will be lost in translation, leading to samples that are the wrong size, the wrong material, or the wrong construction—wasting your time and money.

To ensure your knitted beanie is manufactured exactly to your specifications, you must create a comprehensive Technical Pack (or "tech pack"). This document is the universal blueprint for apparel production, detailing every single element—from measurements and materials to construction techniques and branding placement. It is the single most important tool for eliminating errors and ensuring consistent quality.

As the owner of Shanghai Fumao Clothing, I can tell you that receiving a detailed tech pack from a client is a game-changer. It tells us that we are working with a professional who is serious about their product. It removes ambiguity and allows our team to create an accurate sample on the very first try. Think of it as the architectural plan for your product; without it, you're just hoping the builder "gets" your idea. Let's walk through the essential components you need to include.

What Are the Core Components of Any Tech Pack?

You're starting with a blank document, and the task of creating a tech pack feels overwhelming. You're not a technical designer, and you're unsure what information is essential versus what is just "nice to have." This uncertainty can lead to creating an incomplete document, which is almost as bad as having no document at all, as it can still lead to production mistakes.

Every professional tech pack, regardless of the product, is built on a foundation of four core components: a detailed cover sheet, a Bill of Materials (BOM), a Graded Specification Sheet (Graded Spec), and a Construction Details page. These sections work together to provide a complete 360-degree view of your product.

These components are the universal language of apparel manufacturing. They provide a logical flow of information that any factory, anywhere in the world, can understand.

- Cover Sheet: A quick, top-level summary of the product.

- Bill of Materials (BOM): The "recipe" listing every single physical item needed.

- Graded Spec Sheet: The precise measurements for all sizes.

- Construction Details: The "how-to" instructions for putting it all together.

Mastering these four sections is the key to creating a professional tech pack that protects your brand and ensures your vision is executed flawlessly. We'll explore the specifics for a beanie in the following sections.

What software should I use to create a tech pack?

While you can use a simple spreadsheet program like Microsoft Excel or Google Sheets, the industry standard is Adobe Illustrator. Illustrator is ideal for creating the precise technical sketches (flats) that form the visual core of the tech pack. Many brands use a combination: Illustrator for the drawings and Excel for the measurement and BOM charts. There are also specialized tech pack software solutions like Techpacker that offer templates and collaboration tools.

Does a tech pack need to be complicated?

No, it needs to be clear. Clarity is more important than complexity. Use simple language, clear drawings, and logical layouts. Avoid jargon where possible. The goal is to make it impossible to misinterpret your instructions. A simple, clear tech pack is infinitely better than a complicated, confusing one.

How Do I Specify the Beanie's Materials and Yarn?

You've told your factory you want a "soft, blue, acrylic beanie." But "soft" is subjective, and there are thousands of shades of blue and dozens of types of acrylic yarn. This vagueness is a recipe for a sample that doesn't match your expectations. The factory will have to guess, and their guess will likely be wrong, leading to frustrating and costly revisions.

You must specify your materials with absolute precision in the Bill of Materials (BOM) section. For a knitted beanie, the most critical information is the exact yarn composition, weight, and color, along with details for all branding elements like labels and tags.

The BOM is your product's ingredient list. Every single component must be listed with as much detail as possible to eliminate any room for substitution or error. For a beanie, your BOM should be a chart with columns for: Component, Material/Composition, Color, Supplier (if you have one), and Placement. This level of detail, a standard practice taught by fashion schools like Parsons School of Design, is non-negotiable for professional production.

How do I specify the yarn?

This is the most important part of a beanie tech pack. Be as specific as possible:

- Composition: Don't just say "acrylic." Say "100% Recycled Acrylic" or "50% Merino Wool / 50% Acrylic Blend."

- Yarn Weight/Ply: Specify the yarn's thickness, for example, "2/30" (2-ply, 30 gauge). This determines the fineness of the knit.

- Color: Provide a universal color code. The industry standard is Pantone TCX (for cotton/fabric) or TPG (for paper/hard goods). For example, "Pantone 19-4052 TCX Classic Blue."

- Knit Type: Specify the stitch, such as "1x1 Rib Knit," "2x2 Rib Knit," or "Waffle Knit."

What about labels and branding?

Every piece of branding must be included in the BOM.

- Main Brand Label: Specify if it's a woven or printed label. Include its exact dimensions, colors (with Pantone codes), and placement (e.g., "sewn onto front cuff, centered"). Attach the label's artwork file to the tech pack.

- Care/Content Label: List the required information: fiber content ("100% Acrylic"), country of origin ("Made in China"), and washing instructions (e.g., "Machine wash cold, lay flat to dry").

What Measurements Are Needed for a Beanie?

You want your beanie to have that perfect, slouchy-but-not-too-slouchy fit. But how do you communicate that precise fit to a factory? Simply saying "make it a standard adult size" is a gamble. One factory's "standard" might be another's "small," leaving you with a product that doesn't fit your target customer.

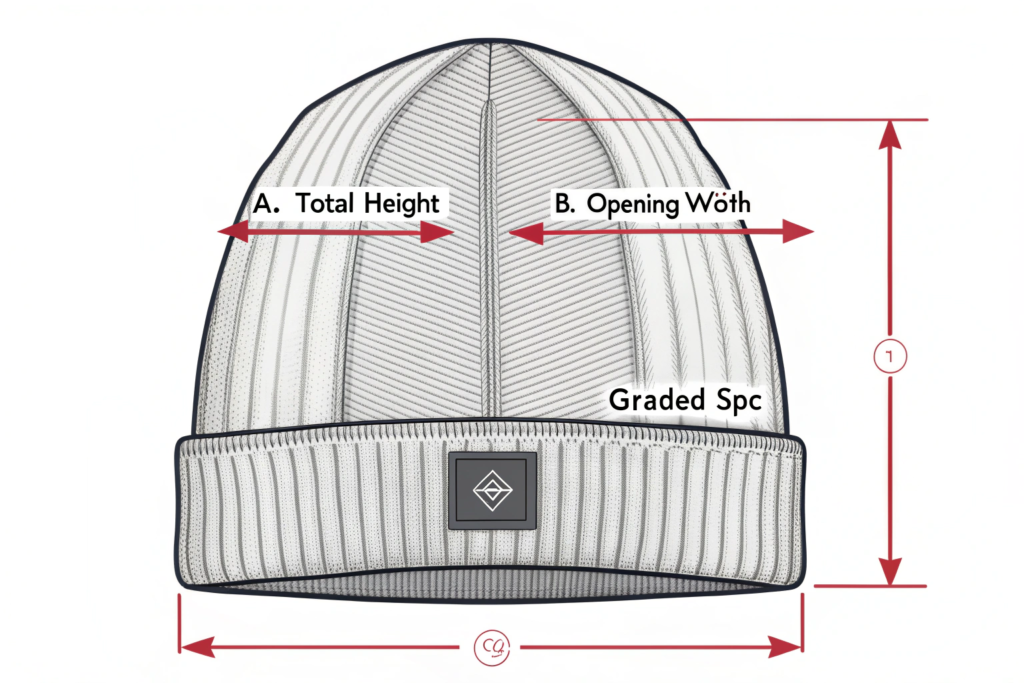

You must provide exact measurements for your beanie in a Graded Specification Sheet. For a beanie, the key measurements are the opening width, the total height, and the cuff height. These specs must be provided for your sample size and then "graded" for any other sizes you plan to produce.

The Graded Spec sheet is the dimensional blueprint of your product. It's a chart that lists every measurement point, the measurement for your base sample size (e.g., Medium), and the adjusted measurements for all other sizes (e.g., Small, Large). The beanie should be measured lying flat and relaxed. This is a critical quality control document that we at Shanghai Fumao Clothing use to ensure every beanie we produce is the correct size.

What are the essential points of measure (POMs) for a beanie?

For a standard cuffed beanie, you need at least these three measurements:

- A - Opening Width: Measured across the bottom opening of the beanie, lying flat.

- B - Total Height: Measured from the center top of the beanie down to the bottom edge.

- C - Cuff Height: Measured from the bottom edge up to the top of the cuff fold.

Include a clear, simple technical sketch (a "flat") with arrows pointing to these measurement points, labeled A, B, and C, so the factory knows exactly where to measure.

How do I "grade" the sizes?

"Grading" is the process of creating measurements for a full-size range based on your sample size. For a beanie, the grading rules are simple. The width and height will typically change by a small, consistent amount between sizes. For example:

- Size S: Width 20cm, Height 28cm

- Size M (Sample Size): Width 21cm, Height 29cm

- Size L: Width 22cm, Height 30cm

The cuff height often remains the same across all sizes. Providing these graded specs allows the factory to create patterns for your entire size run.

How Do I Detail the Construction and Finishing?

You've specified the materials and measurements, but how will the beanie be physically assembled? How should the top be closed? How should the cuff be attached? If you don't specify these details, the factory will use their default method, which may not match the quality or aesthetic you want. For example, they might use a simple, bulky seam at the top instead of the clean, flat finish you envisioned.

You must provide clear, specific instructions for how the beanie is to be constructed and finished. This includes details on the type of seams, the method for closing the top of the beanie, and how the cuff and any labels are to be attached. Use close-up drawings and simple notes to illustrate these points.

This section prevents shortcuts and ensures a high-quality finish. Think of yourself as writing the assembly manual. Use visual callouts on your technical sketches to point to specific areas and add a note explaining the required technique. This is where you define the "craftsmanship" of your product. Reputable sourcing guides, like those from Maker's Row, emphasize this section as crucial for elevating a product from basic to premium.

What are the key construction details for a beanie?

For a knitted beanie, focus on these critical points:

- Top Closure: This is very important for the beanie's shape. Specify how the top opening should be gathered and sewn shut. A common, high-quality method is a "6-point star closure," which creates a clean, flat finish.

- Cuff Construction: Specify if the cuff is a separate piece or a "fold-over" cuff that is part of the main beanie body. State that the cuff should be tacked in place with a few stitches on the side seams to prevent it from unrolling.

- Label Attachment: Detail exactly how the brand label should be sewn on. For example, "Center woven label on front cuff. Sew on all four sides with thread matching the label background color."

What about finishing and packaging?

Don't forget the final steps! Your tech pack should include instructions for:

- Finishing: "Trim all loose threads. Steam press to remove wrinkles."

- Folding and Packing: Provide a simple diagram showing how each beanie should be folded.

- Packaging: Specify the type of polybag to be used, any required warning labels (like a suffocation warning), and how many units should go into a master carton.

Conclusion

Creating a comprehensive tech pack is an essential discipline for any serious brand owner. It is the most effective tool you have to translate your creative vision into a tangible, high-quality product. By meticulously detailing every component, measurement, and construction method for your knitted beanie, you eliminate guesswork, reduce errors, and empower your manufacturing partner to do their best work. It transforms the production process from a relationship of hope and chance into one of clarity, precision, and trust.

AtShanghai Fumao Clothing, a detailed tech pack is the foundation of a successful partnership. It allows us to move faster, produce more accurate samples, and deliver the exceptional quality your brand deserves. If you have a vision for your next accessory line and need a manufacturing expert to help bring your detailed tech pack to life, we are ready to collaborate. Please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com to start the conversation.