You've selected the perfect fabric, dialed in the colors, and finalized your logo embroidery. But when you get the first sample of your custom baseball cap, the brim feels wrong—it's either floppy and limp, losing its shape instantly, or so rigid it feels like a plastic visor. The stiffness of the brim is arguably the most critical functional and aesthetic feature of a cap, directly impacting wearer comfort, shape retention, and the overall brand perception of quality. So, how do you navigate this crucial specification to ensure your caps meet both design intent and user expectations?

Choosing the right stiffness for a baseball cap brim is a strategic decision based on four key factors: Intended Use & Audience, Material & Construction, Desired Silhouette, and Brand Identity. There is no universal "best" stiffness; a flexible, unstructured brim is ideal for a casual, retro-style dad hat, while a firm, pre-curved brim is essential for a performance-driven athletic or trucker cap. The choice dictates how the cap will be worn, how long it will maintain its shape, and the "hand-feel" that communicates quality to the customer. It’s a balance between structure, comfort, and durability.

This guide will break down the spectrum of brim stiffness—from soft and unstructured to rigid and reinforced—and provide a clear framework for making the optimal choice for your specific product line. Understanding the components and terminology is the first step to specifying the perfect brim for your custom caps.

What Are the Different Levels of Brim Stiffness and Their Uses?

Baseball cap brim stiffness exists on a spectrum, typically categorized into three main levels: Soft/Unstructured, Medium/Standard, and Stiff/Reinforced. Each level serves different purposes and caters to distinct market segments.

1. Soft/Unstructured Brim: Often found in "dad hats" or campaign-style caps. These brims have minimal to no internal stiffener. They are sewn with multiple layers of fabric (like 5 or 6-panel construction) but lack a firm insert. The result is a brim that is pliable and flexible, conforming easily to the wearer's touch. It offers a casual, lived-in, and vintage aesthetic right out of the box. This style is popular for streetwear, lifestyle brands, and casual apparel where comfort and a relaxed vibe are paramount. However, it provides little sun protection shape and can become misshapen more easily.

2. Medium/Standard Stiffness: This is the classic baseball cap feel. The brim contains a flexible plastic insert (often PVC or PET) that provides defined structure but retains some bend. It typically comes pre-curved from the factory. This offers an excellent balance: it holds a recognizable cap shape, provides good frontal sun coverage, and allows the wearer to personalize the curve slightly. It's the versatile workhorse, suitable for branded corporate caps, fan merchandise, and general fashion. It appeals to the broadest audience because it feels substantial without being rigid.

3. Stiff/Reinforced Brim: Used in performance, athletic, and "flat-brim" caps. These brims incorporate a thicker, more rigid plastic insert (like a stiff PET sheet) or even a fiberglass or carbon fiber-reinforced board. They are designed to hold a perfectly flat or sharply curved shape indefinitely, resisting bending from handling or wind. This is critical for athletes who need consistent sun glare protection and for the "snapback" aesthetic where a flat, pristine brim is a style statement. It conveys a sense of high-tech performance and crisp, new-era style.

Selecting the right level starts with asking: How will this cap be worn? A brand focused on golf apparel needs a stiff brim for sun protection; a coffee shop giving away promotional caps might choose a soft brim for universal, broken-in comfort. Manufacturers like Shanghai Fumao Clothing can guide you through these options, providing samples with different brim inserts so you can physically assess the hand-feel and structure before bulk production.

What is a "buckram" and how does it differ from a plastic insert?

Buckram is a traditional stiffening material made from starched, open-weave fabric (often cotton or linen). It was historically used in hat-making to provide a soft, moldable structure. In modern cap manufacturing, buckram typically refers to a fusible or sew-in fabric interfacing used in the crown panels to give the cap its structure, not in the brim. The brim is almost always stiffened with a plastic insert (called a "brim board" or "visor insert"). Confusion arises because some suppliers use "buckram" loosely. Always clarify: for the brim, you are selecting a plastic sheet insert of a specific thickness and flexibility (measured in gauge or simply as soft/medium/hard).

Can you have a stiff brim on a unstructured cap crown?

Yes, this is a specific and popular style, often seen in high-end fashion or hybrid caps. It features a soft, unstructured crown (no front-panel buckram, giving a relaxed, rounded profile) paired with a medium or stiff brim. This combination offers the comfort and casual look of a dad hat with the functional sun shade and defined shape of a classic brim. It's a nuanced choice that signals a designed, considered product. Specifying this requires clear communication with your manufacturer to ensure the brim insert is matched appropriately to the crown's construction.

How Does Material Choice Impact Brim Performance and Feel?

The brim is a composite material: the external fabric, the internal stiffening insert, and the stitching that binds them. Each component's properties dramatically affect the final product's performance, durability, and cost.

Fabric's Role: The outer fabric must be durable and capable of holding a tight seam. Common choices include:

- Cotton Twill: Traditional, breathable, molds to the wearer over time. Works well with all stiffness levels.

- Polyester or Nylon: More durable, colorfast, and often used for performance caps. Their slight stretch can affect how a stiff brim feels; a very rigid insert in a stretchy fabric can feel disconnected.

- Technical Fabrics: (e.g., Supplex, Drifit). Used with stiff brims for athletic caps. They are lightweight and wicking but may require specific insert types to prevent show-through or puckering.

A key consideration is "grinning"—when the fabric pulls away from the brim insert at the curve, creating an unsightly gap. A higher-quality, stiffer insert and proper sewing technique minimize this.

Insert Material & Thickness: This is the heart of stiffness.

- PVC (Polyvinyl Chloride): A common, cost-effective option. Can be manufactured in varying flexibilities. Lower-quality PVC may become brittle and crack over time, especially in extreme temperatures.

- PET (Polyethylene Terephthalate): A higher-grade, more environmentally stable plastic. It's more resilient, less prone to warping in heat or cold, and often used for medium to stiff brims. Recycled PET inserts are a growing sustainable option.

- Specialty Materials: For ultra-stiff brims, fiberglass-reinforced board or injected molded plastic inserts are used. These are common in high-performance athletic and military-style caps.

Thickness is usually measured in gauge (e.g., 1.0mm, 1.5mm). A thicker gauge means a stiffer brim, but also more weight. The perfect balance avoids a top-heavy feel.

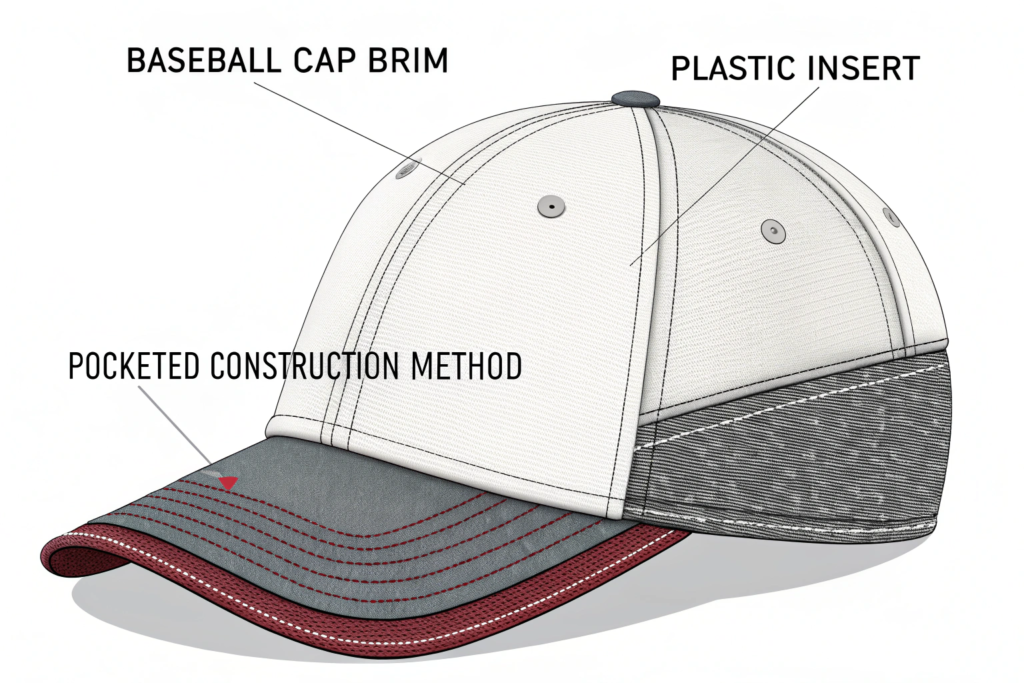

Stitching & Construction: The perimeter stitching (visor stitching) locks the insert in place. Multiple rows of stitching (e.g., 5-7 rows) not only add a decorative touch but also secure the insert more evenly, preventing shifting and improving durability. For stiff brims, the insert is often "pocketed"—fully encased within the fabric layers before stitching, creating a cleaner finish and preventing the insert's edge from being felt by the wearer.

What is the difference between a sewn-in and a pocketed brim insert?

- Sewn-In Insert: The plastic board is placed between the top and bottom fabric layers, and the perimeter is stitched through all layers, trapping the insert. The raw edge of the insert is inside the seam. This is standard but can sometimes lead to a slightly thicker, more abrupt edge.

- Pocketed (or Enclosed) Insert: The top and bottom brim fabrics are first sewn together around three edges, creating a pocket. The plastic insert is then slid into this pocket, and the final edge is stitched closed. This method creates a cleaner, flatter, and more professional finish, as the insert is fully contained. It's a mark of higher-quality construction and is highly recommended for caps where premium details matter.

How does climate or end-use affect material selection?

Climate and use are critical:

- Hot/Humid Climates & Athletic Use: Avoid PVC inserts that can soften and warp. Choose PET or recycled PET for stability. Pair with moisture-wicking fabric.

- Cold Climates: Avoid low-grade PVC that can become brittle and snap. PET is again more reliable.

- Frequent Washing: The insert must resist delamination from fabric layers. A pocketed construction and stable PET insert will fare better over many wash cycles.

- Maritime or Outdoor Work: Corrosion-resistant brass grommets and UV-stable fabrics/inserts are needed to prevent fading and degradation.

What Are the Trends and Branding Implications of Brim Stiffness?

Brim stiffness is not just a technical spec; it's a non-verbal brand communicator. The choice you make sends a immediate message about your brand's personality, target customer, and price point before anyone even reads the logo.

Trends by Segment:

- Streetwear & Lifestyle: Dominated by the soft, unstructured dad hat and the mid-stiffness, slightly curved cap. The look is effortless, vintage, and comfortable. Brands here might use a softer brim to align with a relaxed, creative identity.

- Athletic & Performance: Defined by stiff, pre-curved or flat brims. This communicates precision, technology, and seriousness. Think Nike, Under Armour. The brim is a tool for performance.

- High Fashion & Designer: Often plays with proportion and contradiction. You might see an extremely stiff, oversized flat brim on a luxury fabric, or a very soft brim on a structured crown. The choice is avant-garde and intentional.

- Corporate & Promotional: Typically the classic medium-stiffness, pre-curved cap. It's safe, professional, and widely acceptable. It says "reliable" and "standard."

The "handshake test" is real. When a potential customer picks up a cap, the first thing they do is gently flex the brim. A cheap, floppy brim feels insubstantial. A well-made, medium-stiff brim with a smooth flex and strong return feels like quality. A stiff, robust brim feels professional and durable. This tactile experience directly influences perceived value and willingness to pay a premium. For a brand like Shanghai Fumao Clothing's clients, specifying the correct brim stiffness is a direct investment in brand equity and customer satisfaction.

Why is the flat brim trend associated with youth culture?

The flat brim (worn perfectly flat, often with stickers left on) originated in hip-hop and skateboarding cultures and is strongly associated with youthful rebellion, authenticity, and being "fresh out the box." It represents a rejection of the broken-in, curved-brim norm of previous generations. For a brand targeting Gen Z or Millennials, offering caps with a stiff brim capable of holding a flat shape is essential to tapping into this cultural code. It signals that the brand is current and understands the nuances of subcultural style. The stiffness is what enables the style statement.

How can brim choice differentiate a product line?

A savvy brand can use brim stiffness to create tiered product lines.

- Entry-Level / Promo Cap: Soft to medium unstructured brim. Cost-effective, mass appeal.

- Core / Classic Cap: Medium-stiffness, pre-curved brim with quality fabric. The reliable best-seller.

- Premium / Performance Cap: Stiff, pocketed brim with recycled PET insert and technical fabric. Commands a higher price and builds brand reputation for quality.

This strategy allows you to cater to different customer needs and price sensitivities under one brand umbrella, using a tangible feature (brim feel) to justify the price differentiation.

How to Test and Specify Brim Stiffness with Your Manufacturer?

Moving from concept to consistent production requires clear, objective communication with your factory. You cannot simply say "make it stiff." You must define and test the specification.

1. Request Physical Samples: Always ask your manufacturer for "brim board" or "insert" samples separately, and in finished cap samples. Feel the raw insert for its flex and snap-back. Then, evaluate it in a completed cap to understand the full effect with fabric and stitching.

2. Define by Benchmark: The easiest method is to provide a sample cap (even a competitor's cap) that has the exact brim feel you want. Say, "Match the stiffness and curve of this cap." This gives the factory a physical target.

3. Understand Their Terminology: Ask what materials they use (PVC, PET, recycled PET) and what thickness/gauge they recommend for your desired outcome. Ask for their standard options: e.g., "Soft (for dad hat)," "Medium (standard curved)," "Hard (flat brim)."

4. Perform Functional Tests:

- Flex Test: Gently bend the brim up and down 10-15 times. Does it return to its original shape without creasing?

- Twist Test: Gently twist the brim. Does it resist warping?

- Pressure Test: Press on the center of the brim. Does it collapse easily or hold firm?

- Visual Check: Look for grinning (fabric pulling away) at the curve, especially on the underside.

5. Formalize the Spec: Once approved, include the brim specification in your Tech Pack:

- Brim Stiffness: E.g., "Medium-Standard, pre-curved."

- Insert Material: E.g., "1.2mm Recycled PET Board."

- Construction: E.g., "6-row stitch, pocketed insert construction."

- Approved Sample ID: Reference the specific sample cap that was signed off.

This eliminates guesswork and ensures consistency across production runs, whether you're making 500 or 50,000 caps.

What questions should you ask your cap factory about brims?

To ensure quality and clarity, ask:

- "What material do you use for brim inserts? (PVC, PET, other?)"

- "Do you offer different stiffness levels? Can I get samples of each?"

- "What is your standard construction method? Sewn-in or pocketed insert?"

- "How do you prevent 'grinning' on curved brims?"

- "What is the MOQ if I want to use a custom insert material or thickness?"

- "Can you provide a finished cap sample with my exact fabric and desired brim stiffness before production?"

Their answers will reveal their expertise and capability to execute your vision.

How to ensure consistency in large production runs?

Consistency is a hallmark of quality. To achieve it:

- Source from a Reliable Insert Supplier: The factory should use a consistent, quality-controlled source for their plastic boards, not random market materials.

- Implement In-Line QC: The factory should have a check to visually and manually feel brim stiffness on random caps during production.

- Conduct Pre-Shipment Inspection: Your third-party or internal QC should include brim stiffness as a test point, using your approved master sample as the benchmark.

- Approval of Bulk "Top-of-Production" Samples: Before the full run is completed, have the factory send you 2-3 caps from the start of production. Check if the brim matches your approved sample.

Conclusion

Choosing the right stiffness for a baseball cap brim is a critical decision that blends ergonomics, aesthetics, branding, and material science. It requires moving beyond a simple preference to an informed specification based on your cap's purpose, your brand's identity, and your customer's expectations. From the laid-back flex of a dad hat to the unyielding structure of a performance flat-brim, each choice tells a story and serves a function.

By understanding the spectrum of options, collaborating closely with your manufacturer on materials and construction, and rigorously testing prototypes, you can ensure your caps deliver not only on style but also on the subtle, tactile quality that turns a simple accessory into a beloved product. The perfect brim feels intentional—it's the foundation upon which the cap's character is built.

If you are developing a line of custom baseball caps and want expert guidance on specifying the perfect brim stiffness, fabric, and construction, we are here to help. At Shanghai Fumao Clothing, we have extensive experience crafting caps for every segment, from fashion-forward streetwear to durable promotional gear. We can provide material samples and prototypes to bring your vision to life with precision. Contact our Business Director, Elaine, to start your cap project: elaine@fumaoclothing.com.