Are you buying summer clothing and accessories but still getting sunburned through the fabric? Do you wonder why some lightweight garments feel cool but offer zero protection, while others feel stifling? Many people assume that any piece of clothing acts as a sun barrier, but the reality is that not all fabrics are created equal when it comes to UV protection.

The good news is that with the right knowledge, you can select fabrics that are both comfortable for summer heat and highly effective at blocking harmful ultraviolet (UV) rays. The best fabric for sun protection is a combination of material type, weave density, color, and construction. By understanding these key factors, you can make informed choices not just for your personal wardrobe, but also for sourcing or manufacturing high-demand summer products like hats, scarves, and lightweight cover-ups that truly protect your customers.

This guide will break down the science and sourcing strategy into clear, actionable steps. We will explore the core principles of how fabric blocks UV rays, compare the strengths of natural vs. synthetic fibers, analyze the crucial roles of color and fabric finish, and finally, provide a practical sourcing checklist. Let's ensure your next summer collection is as safe as it is stylish.

What is UPF and How Does Fabric Structure Block UV Rays?

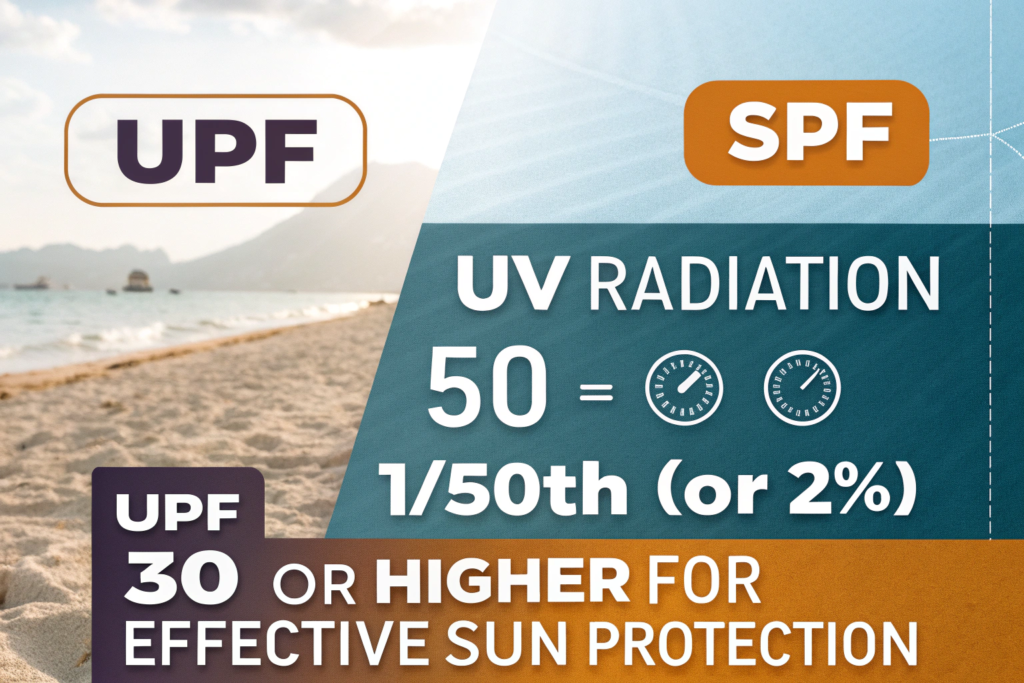

Before choosing a fabric, you must understand the metric of protection: UPF (Ultraviolet Protection Factor). Similar to SPF for sunscreen, UPF measures how much UV radiation (both UVA and UVB) can penetrate a fabric. A UPF of 50 means only 1/50th (or 2%) of the sun's UV rays can pass through. For effective sun protection, look for fabrics with a UPF rating of 30 or higher.

The fabric's ability to block UV depends more on its construction than its fiber content alone. Two primary structural factors are at play: the tightness of the weave or knit and the thickness of the yarns. A tightly woven fabric, like a dense poplin or a fine twill, has smaller gaps between threads, leaving less room for UV rays to slip through. Conversely, a loose, open weave like in some linen or crochet items offers minimal protection regardless of material. Hold the fabric up to a light source; if you can see a lot of light passing through, UV radiation is likely passing through as well.

Why is Weave Density More Important Than Fiber Type?

It's a common misconception that natural fibers like cotton are inherently better for sun protection. The truth is, a loosely woven white cotton shirt may have a UPF as low as 5. The weave density is the first and most critical line of defense. Think of it as a shutter; the smaller the gaps, the less sunlight gets in. Densely woven fabrics such as denim, canvas, or twill naturally have high UPF ratings because of their tight construction. For summer products where breathability is also key, look for fabrics with a high thread count made from fine yarns. This creates a smooth, tight surface that blocks UV while still allowing air circulation. When sourcing fabrics for products like sun-protective scarves or hats, always ask suppliers for the fabric's thread count and, ideally, a certified UPF test report. Reputable fabric testing labs like Intertek or SGS provide these certifications.

How Does Stretch and Wear Affect a Fabric's UPF?

A fabric's UPF is not static; it degrades with use. This is a crucial point for manufacturers and consumers alike. Stretch fabrics pose a particular challenge. When a knitted or spandex-blend fabric is stretched, the threads pull apart, increasing the gaps and significantly reducing its UPF rating. A fitted garment may offer less protection on the stretched areas (like elbows or knees). Furthermore, general wear and tear—such as fabric thinning, pilling, and fading—compromises the protective barrier. Moisture is another factor; some fabrics like cotton become more transparent when wet, lowering their UPF. When developing sun-protective products, it's essential to conduct durability tests. At Shanghai Fumao Clothing, our quality control process for items like sun hats and cover-ups includes testing material under stress and after simulated wash cycles to ensure the UPF claim remains valid throughout the product's lifespan.

Are Natural or Synthetic Fibers Better for Sun Protection?

The debate between natural and synthetic fibers is ongoing, but for sun protection, synthetics often have a structural advantage. Polyester and Nylon are inherently more UV-resistant than many natural fibers. This is because their polymer chains absorb UV radiation more effectively. Additionally, synthetic fibers can be engineered from the outset to be smooth and fine, allowing them to be woven into very tight, lightweight fabrics with high UPF ratings. Many high-performance sun-protection clothing lines rely on specially engineered polyester or nylon blends.

However, natural fibers have their place, especially when comfort and breathability in extreme heat are priorities. Merino wool is a surprising champion; it naturally absorbs UV radiation and can be woven into breathable, temperature-regulating fabrics. The key for natural fibers like cotton or linen is to choose them in their densest, heaviest weaves (like chambray or linen canvas) and in darker colors to boost their protective capabilities. For a balanced approach, blended fabrics that combine the UV resistance of polyester with the moisture-wicking comfort of cotton are popular in the market.

What are the Advantages of Engineered Synthetic Fabrics?

Engineered synthetic fabrics are the workhorses of modern sun protection. Brands like Coolibar and Columbia use proprietary fabrics where UV-inhibiting compounds are embedded directly into the polymer before the fiber is even spun. This creates a protection that won't wash out. These fabrics are also excellent at moisture-wicking, pulling sweat away from the skin to keep the wearer cool and dry—a critical feature for summer activewear. Furthermore, their durability and colorfastness are superior, meaning the fabric's protective integrity and dark color (which aids protection) last longer. For manufacturers, sourcing these high-tech fabrics requires partnering with specialized mills. We work with such suppliers to produce high-UPF baseball caps, knit hats with UV protection, and lightweight gloves. Resources like Textile Exchange provide insights into sustainable innovations in synthetic fabrics.

Can Natural Fibers Like Linen and Cotton Be Effective?

Yes, but they require careful selection and treatment. A heavy, tightly woven linen in a dark color can provide good sun protection while offering exceptional breathability, making it ideal for stylish summer scarves and loose cover-ups. For cotton, the gold standard is denim—its dense twill weave gives it a naturally high UPF. However, for lighter-weight cottons, look for products that have been treated. Many fabrics now receive a UV-absorbing finish during the dyeing process. This treatment, which often uses compounds like titanium dioxide, enhances the fabric's UPF without significantly affecting its hand feel. When sourcing natural fabrics, it's imperative to ask the mill or supplier about any UV treatments and request test reports. It's also wise to consider fabric blends; a cotton-polyester blend can offer a softer feel with improved durability and UV resistance over pure cotton.

How Do Color and Fabric Treatments Enhance UV Blocking?

Color is not just an aesthetic choice; it's a functional one in sun protection. Darker and brighter colors (like black, navy, red, or emerald green) absorb more UV radiation, preventing it from reaching your skin. Light colors, especially white and pastels, reflect more visible light but can allow UV rays to pass through more easily. Think of a dark umbrella versus a light one; the dark one creates a more shaded environment underneath. The depth of the dye also matters. A fabric dyed with a higher concentration of pigment will generally offer better protection.

Beyond color, specialized fabric treatments are game-changers. These include UV-inhibiting finishes applied to the fabric and UPF-boosting laundry additives for consumers. For manufacturers, the treatment integrated during production is most reliable. These treatments can be chemical (like the previously mentioned titanium dioxide) or physical, such as creating a micro-porous structure that scatters UV light.

Why Do Darker Colors Provide Superior Protection?

The science is straightforward: absorption. Darker dyes contain more pigments (like carbon black or deep blues) that absorb a broader spectrum of light energy, including harmful UV rays, and convert it to a small amount of heat. A black cotton t-shirt will always have a higher UPF than an identical white one made from the same fabric. This principle is vital when designing products meant for intense sun exposure. For example, the underside of a straw hat's brim is often lined with a dark, tightly woven fabric to block reflected UV rays from sand, water, or concrete. When advising clients at Shanghai Fumao Clothing on product development, we emphasize using dark linings and trims on sun-protective items to enhance their efficacy without compromising the outer aesthetic.

What Role Do Specialized Finishes and Coatings Play?

Specialized finishes are the secret weapon for creating lightweight, comfortable fabrics with high UPF. These finishes work by either absorbing UV radiation themselves or by scattering it. A common example is the application of ceramic particles (like zinc oxide) to the fabric surface. These particles are excellent at reflecting and scattering UV light. Another advanced technology involves creating a fabric with a textured, opaque surface that diffuses light. For end-users, there are also laundry detergents with UV absorbers that can renew or boost the UPF of existing clothing with each wash. From a manufacturing standpoint, partnering with mills that offer these patented finishes ensures your products stand out in the market with verifiable claims. It's important to note that these coatings can affect breathability and hand feel, so rigorous testing is required. Industry standards for testing UV protective textiles are well-documented by organizations like the American Association of Textile Chemists and Colorists (AATCC).

What is the Practical Checklist for Sourcing Sun-Protective Fabrics?

For importers, brands, and product developers, translating this knowledge into a sourcing strategy is key. You need a practical checklist to evaluate potential fabrics and suppliers to ensure you get materials that are effective, durable, and compliant with market claims. Relying on supplier assurances is not enough; you need verifiable data.

Your checklist should start with requesting a laboratory UPF test report (e.g., following AS/NZS 4399:1996 or ASTM D6603 standards) from an accredited third-party lab. Next, examine the fabric construction—ask for thread count, weight (gsm), and a physical sample to perform the "light test." Inquire about colorfastness and durability tests, especially for stretch and wet conditions. Finally, understand any chemical treatments used and ensure they are compliant with relevant safety regulations (like OEKO-TEX Standard 100).

Which Certifications and Test Reports Are Non-Negotiable?

To avoid liability and build consumer trust, certain documents are non-negotiable. The most important is a UPF certification from a recognized lab. This report should state the tested UPF rating (e.g., UPF 50+) and specify if it was tested new, after washing, and/or when wet. For products sold in Australia, compliance with the ARPANSA standard is often required. Secondly, a material safety data sheet (MSDS) or an OEKO-TEX certificate is crucial if chemical finishes are used, proving the fabric is free from harmful substances. For brands focused on sustainability, certifications like Global Recycled Standard (GRS) for recycled polyester can add value. Always verify these certificates directly with the issuing organization when possible. As a professional manufacturer, we provide these documents to our clients as part of our transparent project management service, ensuring a smooth customs clearance process.

How to Balance UPF, Breathability, and Cost in Production?

Achieving the perfect balance is the core challenge in product development. A thick, dark, tightly woven fabric may have a UPF of 50+ but be too hot for summer. The solution lies in selecting high-tech, lightweight synthetics or fine, dense natural blends. Breathability is measured by metrics like Moisture Vapor Transmission Rate (MVTR), which you can also request from fabric suppliers. Cost is another factor; engineered fabrics with UV-inhibiting polymers are more expensive than basic cotton. The balance is struck by positioning: use higher-cost, high-performance fabrics for core products like hiking shirts or sun hats, and use treated, dense natural fibers for fashion-oriented cover-ups or scarves. Efficient production planning and working with an experienced manufacturer like us can help optimize material usage and keep overall costs controlled without sacrificing the critical protective features that define the product.

Conclusion

Choosing the best fabric for summer sun protection is a multifaceted decision that blends science, design, and savvy sourcing. The ideal fabric boasts a tight weave or knit, leverages the inherent strengths of engineered synthetics or densely constructed naturals, utilizes dark colors or specialized finishes, and comes with verifiable test data. This approach ensures that the final product—whether a chic sun hat, a protective scarf, or a lightweight cover-up—delivers on its promise of safety and comfort.

For businesses, this knowledge translates into a powerful competitive edge. By offering products with genuine, certified sun protection, you build trust with consumers and tap into the growing health-conscious market. It moves beyond simple fashion to functional fashion, a category with strong repeat purchase potential.

If you are looking to develop a line of sun-protective accessories or garments with reliable, high-UPF fabrics, expert manufacturing is key. At Shanghai Fumao Clothing, we specialize in sourcing certified materials and producing quality sun hats, scarves, gloves, and more. Contact our Business Director Elaine to discuss how we can help you create a best-selling, protective summer collection. Reach out to Elaine at elaine@fumaoclothing.com to start your next project.