Are you receiving scrunchie samples where the elastic loses its bounce after a few wears, or worse, snaps during use? Do returns and complaints about stretched-out hair ties eat into your profits and brand reputation? You're facing a critical but often overlooked quality checkpoint. The elastic core is the functional heart of a scrunchie. Its quality determines the product's longevity, comfort, and overall value. A beautiful fabric exterior is meaningless if the elastic inside fails.

Checking elastic quality is a blend of visual inspection, physical testing, and understanding material specifications. Poor-quality elastic is often made from recycled or low-grade rubber with inadequate spandex content, has uneven thickness, or is poorly joined. By implementing a simple yet systematic quality assurance protocol, you can identify substandard components before they ruin your bulk production and reach your customers.

This guide will provide a hands-on methodology. We'll cover how to visually inspect the elastic for construction flaws, perform key physical tests for recovery and durability, verify material composition and safety, and finally, establish quality standards with your supplier. Let's ensure the snap in your scrunchies lasts as long as their style.

What Visual and Manual Inspections Reveal Immediate Flaws?

Before any stress test, a simple visual and tactile examination can flag major problems. This first-pass check takes seconds but can filter out obviously defective elastics that would fail in use.

Key Visual & Manual Checks:

-

Seam/Join Integrity: The elastic is a loop, joined at the ends. This join is the weakest point. Inspect it closely. A high-quality join will be smooth, flat, and secure, often made with a butt join (ends fused together) or a small, neat overlap stitch. A poor join may be bulky, have loose threads, or feel like a hard knot. Gently pull on either side of the join—it should not separate or show significant thinning.

-

Uniformity of Thickness & Color: Run the elastic between your fingers. It should feel consistent in diameter with no thin, weak spots or thick, stiff sections. The color should be even throughout. Spots of discoloration can indicate recycled or contaminated rubber compounds.

-

Surface Texture: Quality elastic has a smooth, slightly glossy finish. Avoid elastics that feel dry, chalky, or have a rough, textured surface, as these may be old, degraded, or made with poor-quality coatings.

-

Coiling Behavior (In the Finished Scrunchie): When you stretch and release a finished scrunchie, the elastic core should cause it to retract smoothly and evenly into its gathered form. It should not twist, knot, or create uneven bunching in the fabric.

How to Identify a Poor-Quality Elastic Join or Splice?

The splice is the Achilles' heel. A bad splice will fail first. Look for these red flags:

- The "Hard Lump": A bulky, glued, or clumsily stitched knot that creates an uncomfortable pressure point and a visual bump in the finished scrunchie.

- Visible Glue Residue: Excess adhesive that has seeped out, feeling sticky or brittle.

- Misalignment: The two ends are not aligned perfectly, causing the loop to have a twisted or uneven section.

A professional supplier will use specialized splicing equipment to create nearly invisible joins. During sampling, explicitly request to see and feel the elastic join on the raw material. This attention to component detail is as important as checking clasp mechanisms on hair hoops.

Why Does Elastic Thickness and Uniformity Matter?

Inconsistent thickness leads to inconsistent performance. A thin spot is a stress concentrator—it will stretch more than the surrounding areas and is prone to breaking. Uniform thickness ensures the tension is evenly distributed around the entire loop, providing a consistent hold and longer life. Use a simple caliper to measure the diameter at several points. Variations should be minimal (e.g., +/- 0.1mm). This precision in specification mirrors the need for accurate dimensions in hat fit.

How to Perform Physical Tests for Recovery and Strength?

Visual checks aren't enough. You must simulate real-world use through standardized physical tests. These tests measure the two most important properties of elastic: Recovery (its ability to return to original length) and Tensile Strength (its resistance to breaking).

Core Physical Tests:

-

The Stretch & Recovery Test (Cyclic Loading):

- Step 1: Measure the original relaxed length (L0) of a loop of the elastic (or mark a section on a longer piece).

- Step 2: Stretch it to a standardized length (e.g., 2x or 3x its original length). Hold for 30 seconds.

- Step 3: Release and let it rest for 60 seconds.

- Step 4: Measure the new relaxed length (L1).

- Calculation: *Recovery % = [(L0 / L1) 100]. A high-quality elastic should recover to at least 90-95%** of its original length after a few cycles. If it stays stretched out (e.g., only 70% recovery), it's low-grade and will cause scrunchies to become loose quickly.

-

The Constant Load (Creep) Test: Hang a standardized weight (e.g., 500g) from the elastic loop for an extended period (e.g., 24 hours). Measure the permanent stretch after removing the weight. Good elastic will show minimal permanent deformation.

-

The "Feel" Test for Tension: Compare the elastic's resistance by stretching it alongside a known good sample. It should require a firm but smooth pull. It shouldn't feel "dead" and too easy to stretch (low spandex content), nor should it feel brittle and harsh.

What is a Simple "In-Hand" Stretch Test for Samples?

For a quick assessment during a supplier meeting or when receiving samples:

- Wrap the elastic around four fingers like a hair tie, stretching it to a comfortable wearing tension.

- Hold it for 15 seconds.

- Remove it from your fingers.

- Observe: Does it spring back immediately to its small, coiled size, or does it hang limply? A good elastic will snap back crisply. A bad one will be sluggish and remain enlarged.

This simple test often correlates well with more formal recovery measurements.

How to Test for Durability Against Repeated Use (Fatigue)?

Simulate long-term wear with a cycle test. If you have a small motorized rig, you can automate this. Manually, you can perform a defined number of stretch-release cycles (e.g., 100 times) on a sample, stretching it to a consistent length each time. After the cycles, perform the Stretch & Recovery Test again. A significant drop in recovery percentage indicates the elastic has poor fatigue resistance and will wear out fast. This proactive testing is a key part of a comprehensive QC system.

How to Verify Material Composition and Safety?

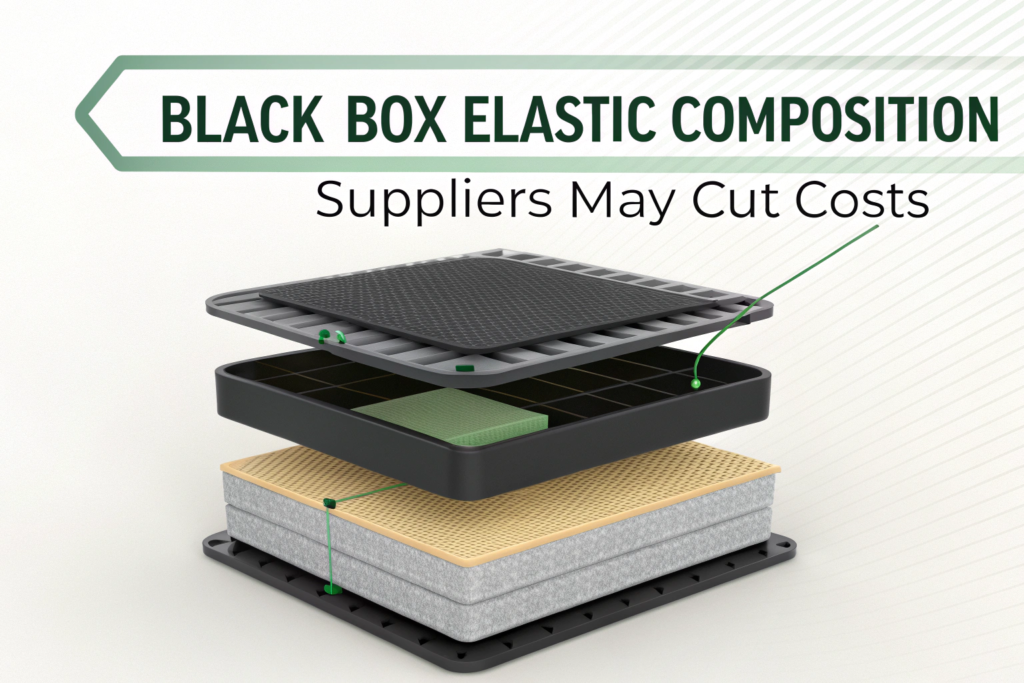

The "black box" of elastic composition is where suppliers often cut costs. What is it made of? Is it safe for prolonged skin and hair contact? Demanding transparency here protects your brand from liability and ensures product safety.

Key questions to ask your supplier:

- Material Composition: Request a specification sheet. Quality elastic for scrunchies is typically a blend of polyester (or cotton) covering with a core of natural rubber latex or synthetic rubber (like polyisoprene) and Spandex (Lycra®). The spandex content (often 5-15%) is critical for recovery.

- Latex-Free Claims: If marketing as latex-free, you need a certificate from the supplier stating the core is synthetic rubber. Be aware that "latex-free" elastic is often more expensive.

- Chemical Safety: Request test reports for compliance with OEKO-TEX Standard 100 or REACH SVHC. This ensures the elastic is free from harmful levels of heavy metals, AZO dyes, and other restricted substances.

A reputable supplier like Shanghai Fumao Clothing will provide this documentation as part of their component sourcing process.

What is the Difference Between Latex and Synthetic Rubber Elastic?

- Natural Rubber Latex: Offers excellent stretch and recovery at a lower cost. However, it can degrade over time with exposure to oils, heat, and UV light (turning yellow and brittle). It also poses a risk for latex allergies.

- Synthetic Rubber (e.g., Polyisoprene): Designed to mimic the properties of natural latex but is more consistent, has better aging resistance, and is hypoallergenic. It is the preferred choice for mid-to-high-end scrunchies, especially for brands concerned about allergies or product longevity.

Specify your requirement clearly. For a premium product, "synthetic rubber core, latex-free" should be the standard.

Why is OEKO-TEX Certification Important for Elastic?

Elastic is in direct, prolonged contact with the skin (wrist) and hair. It can contain chemical softeners, dyes, and accelerators from the rubber vulcanization process. OEKO-TEX Standard 100 certification is an independent verification that the elastic has been tested for a wide range of harmful substances and is safe for human use. It is a widely recognized trust mark, especially important for the European market. Including certified components strengthens your overall product compliance posture.

How to Establish Quality Standards with Your Supplier?

Don't leave elastic quality to chance or verbal assurances. Build objective, measurable standards into your Tech Pack and Quality Control Agreement. This aligns expectations and gives you grounds for rejection if standards aren't met.

Create an Elastic Specification in your Tech Pack:

- Material: e.g., "95% Polyester covered, 5% Spandex, Synthetic Rubber Core (Latex-Free)."

- Width: e.g., "3mm +/- 0.1mm."

- Recovery Standard: e.g., "Must recover to ≥92% of original length after 3 cycles of 200% elongation."

- Join Method: e.g., "Butt-spliced, smooth join, no hard knots."

- Certification: e.g., "Must provide OEKO-TEX Standard 100 certificate for the elastic lot."

Implement Incoming QC: Require the factory to perform a batch test on incoming elastic rolls before production begins. They should check recovery on samples from each roll and keep a record.

Include Elastic in Final Pre-Shipment Inspection: Your third-party inspector's checklist should include a random check of scrunchies where they perform a functional stretch test, checking recovery and inspecting the join integrity.

What are Realistic Tolerance Levels for Elastic Recovery?

After multiple discussions with manufacturers and labs, a realistic minimum standard for a good quality scrunchie elastic is 90% recovery after 3 cycles of stretching to twice its length. Premium elastic should achieve 92-95% recovery. Anything below 85% is unacceptable for a product meant to retain its function. Specify this tolerance in writing. For example: "Sample must meet 90% recovery when tested per our provided method. Bulk material failing this test will be rejected." This turns a subjective "good elastic" into an objective pass/fail criterion.

How to Handle Supplier Pushback on Higher-Quality Elastic?

Expect cost pushback. Your response should be value-based:

- "This specification is non-negotiable for our brand quality. The cost increase of $0.02 per unit is justified to eliminate returns and protect our 5-star reviews."

- "We are willing to sign a longer-term agreement for a higher volume if you can meet this spec at the target price."

- "Can you provide a cost breakdown for latex-free vs. standard elastic so we can understand the difference?"

A professional supplier will respect clear specifications and work with you. One that constantly pushes for lower-quality substitutions is a red flag, indicating they may not be the right long-term partner.

Conclusion

Checking the quality of scrunchie elastic is a vital, multi-step process that combines sharp-eyed inspection, simple but effective physical testing, and rigorous documentation of material safety. By focusing on the join integrity, performing stretch/recovery tests, demanding OEKO-TEX certification, and locking these standards into your supplier agreements, you transform the elastic from a hidden weakness into a pillar of product reliability.

This diligence prevents the most common cause of scrunchie failure, enhances customer satisfaction, and solidifies your brand's reputation for quality where it counts—in daily use.

Tired of inconsistent elastic ruining your scrunchie line? Partner with a manufacturer that sources and tests components rigorously. At Shanghai Fumao Clothing, we specify and validate all elastics for recovery, safety, and durability before they enter production. Contact our Business Director Elaine at elaine@fumaoclothing.com to develop scrunchies that perform as beautifully as they look.