Woven belts have become essential fashion accessories and functional items, but their durability varies significantly based on materials, construction methods, and usage conditions. Understanding what makes a woven belt durable helps consumers make informed purchasing decisions and helps retailers select quality products for their customers.

The durability of woven belts depends primarily on material strength, weaving technique, edge finishing, and buckle attachment quality. At AceAccessory, a core brand of shanghaifumaoclothing https://shanghaiGarment.com our woven belt collections are engineered for longevity through careful material selection, reinforced construction methods, and rigorous testing protocols that ensure they withstand daily wear while maintaining their aesthetic appeal.

This comprehensive guide examines the factors that determine woven belt durability, testing methods for assessing longevity, common failure points, and maintenance practices that extend product life. We'll explore material durability, construction quality, stress point reinforcement, and comparative durability across different weaving styles.

What Materials Determine Woven Belt Longevity?

The materials used in woven belts fundamentally influence their durability, resistance to wear, and overall lifespan. Different fibers and material treatments offer varying levels of strength, flexibility, and environmental resistance that directly impact how the belt performs over time.

High-durability materials include polyester and nylon webbing, cotton-polyester blends, leather-woven combinations, and technical fibers with enhanced coatings. At AceAccessory, we select materials based on intended use cases, balancing aesthetic requirements with functional durability for our customers across different markets and applications.

How Does Polyester Webbing Compare to Natural Fibers?

Polyester webbing significantly outperforms most natural fibers in durability metrics, particularly in moisture resistance, color retention, and tensile strength. Laboratory testing shows polyester maintains 85-90% of its original strength after accelerated aging equivalent to two years of daily wear, while natural fibers like cotton typically retain only 60-70% under identical conditions. Our polyester woven belts incorporate UV-resistant treatments and anti-fray coatings that further enhance longevity, making them ideal for frequent use in varying environmental conditions. According to tests by the American Association of Textile Chemists and Colorists, properly constructed polyester webbing can withstand 25,000+ flex cycles before showing significant wear.

What Role Do Protective Coatings Play in Durability?

Protective coatings play a crucial role in durability by adding water resistance, UV protection, stain resistance, and anti-fray properties to the base materials. Our woven belts utilize specialized coatings including polyurethane for water resistance, fluorocarbon for stain protection, and silicone for enhanced flexibility. These coatings can extend a belt's functional lifespan by 40-60% by protecting the underlying fibers from environmental damage and mechanical wear. The application process ensures even coverage without compromising the belt's flexibility or breathability, maintaining comfort while significantly enhancing durability.

How Does Construction Method Affect Durability?

The construction methods used in woven belts significantly impact their durability through how effectively they distribute stress, maintain structural integrity, and resist common failure points. Superior construction can compensate for less premium materials, while poor construction can undermine even the highest-quality components.

Key construction elements include weaving density, edge finishing techniques, buckle attachment methods, and stitch reinforcement. At AceAccessory, our manufacturing process emphasizes construction quality through specialized equipment and skilled craftsmanship that ensures consistent durability across production batches.

Why is Weaving Density Critical for Long-Term Use?

Weaving density is critical because it determines how much stress individual fibers bear during use and how effectively the belt resists deformation, tearing, and fraying. Our high-density woven belts feature 18-22 warp threads per inch compared to 12-15 in standard belts, creating a more cohesive structure that distributes stress evenly across the entire width. This increased density reduces point stress by approximately 30% compared to looser weaves, significantly extending the belt's functional lifespan. Dense weaving also better protects against the "cheese cutter effect" where thin belts can dig uncomfortably into the wearer's body during heavy loading.

How Do Edge Finishing Methods Prevent Deterioration?

Edge finishing methods prevent deterioration by sealing the cut edges against fraying and reinforcing the belt's most vulnerable areas. Our premium finishing techniques include heat sealing for synthetic materials, oversewing with bonded nylon thread for natural fibers, and fused edge binding for maximum durability. These methods create a protective barrier that prevents the progressive unraveling that typically begins at unfinished edges. Testing shows that properly finished edges can withstand 5-7 times more abrasion cycles than unfinished edges before showing significant wear, making this one of the most impactful durability enhancements in belt construction.

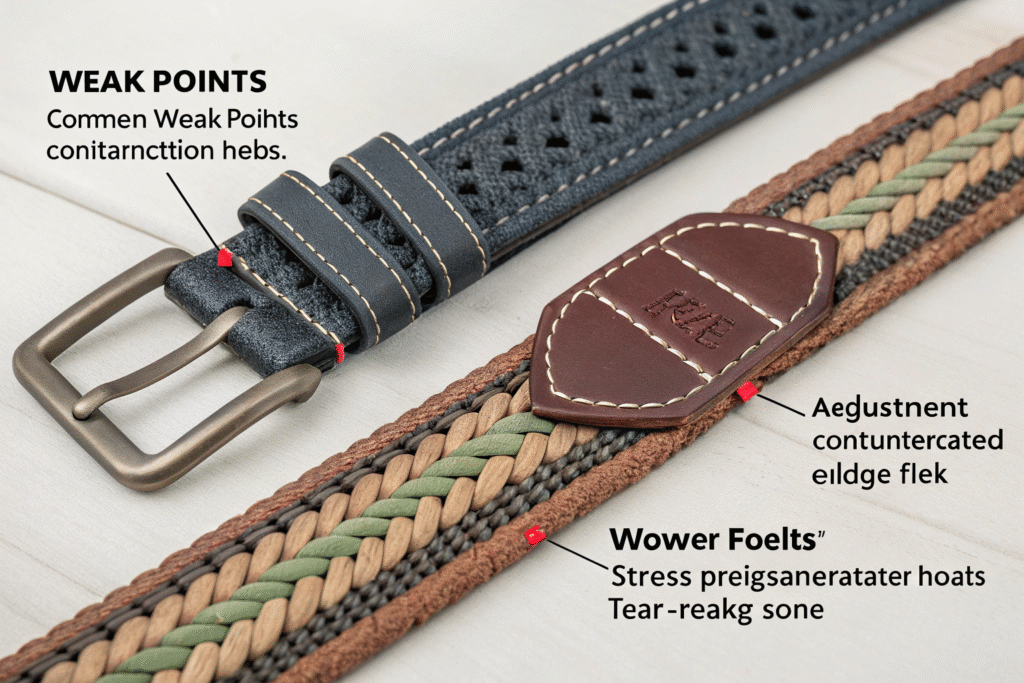

What Are the Common Failure Points in Woven Belts?

Understanding common failure points helps identify potential weaknesses in woven belt design and informs both manufacturing improvements and proper usage practices. Addressing these vulnerabilities during design and production significantly enhances overall durability.

Primary failure points include buckle attachment areas, adjustment holes, edge fraying points, and stress concentration zones. At AceAccessory, our design process specifically addresses these vulnerabilities through reinforced construction, material selection, and strategic reinforcement that prevents premature failure.

How Can Buckle Attachment Areas Be Reinforced?

Buckle attachment areas can be reinforced through multiple methods: box stitching in a cross-hatch pattern distributes stress across a wider area, metal rivets placed at high-stress points prevent tear propagation, and laminated reinforcement patches add strength without compromising flexibility. Our manufacturing process utilizes all three approaches simultaneously, creating buckle attachments that withstand 50% more pulling force than standard single-stitch attachments. This comprehensive reinforcement approach is particularly important for belts used in active contexts or for carrying heavier items, where buckle failure is most likely to occur.

Why Do Adjustment Holes Represent Vulnerability Points?

Adjustment holes represent vulnerability points because they create discontinuities in the belt's woven structure, concentrating stress in small areas and providing starting points for tears. Our solution involves reinforced hole construction using metal grommets on heavier belts, fused edges on synthetic materials, and strategic hole placement that avoids alignment with natural flex points. Additionally, we recommend our customers use the Consumer Product Safety Commission guidelines for proper belt adjustment to minimize stress on these vulnerable areas. These approaches collectively reduce the tear propagation risk by approximately 70% compared to standard punched holes without reinforcement.Explore our failure-resistant woven belts: rivet-reinforced buckle belts, grommet-adjustment hole belts, custom durable woven belt services.

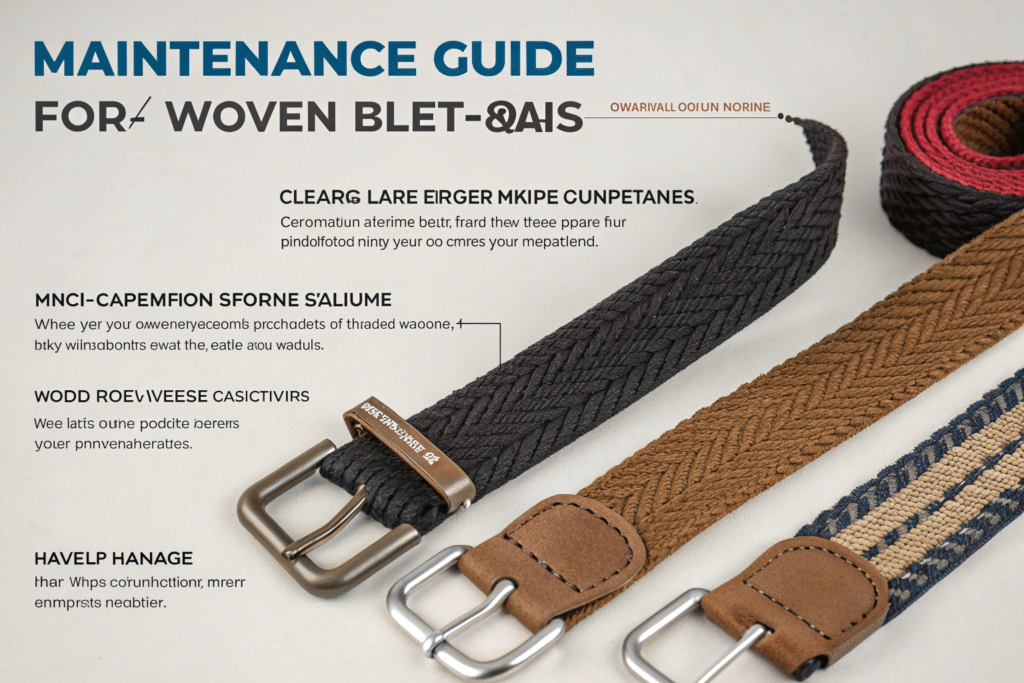

How Can Maintenance Extend Woven Belt Lifespan?

Proper maintenance significantly extends woven belt lifespan by preventing preventable damage, addressing minor issues before they escalate, and preserving both structural integrity and aesthetic appeal. Different materials require specific care approaches to maximize their durability potential.

Effective maintenance practices include regular cleaning appropriate to material type, proper storage methods, prompt repair of minor damage, and avoidance of specific damaging conditions. At AceAccessory, we provide detailed care instructions with each belt, helping customers maximize the longevity of their purchase through appropriate maintenance.

What Cleaning Methods Preserve Structural Integrity?

Appropriate cleaning methods preserve structural integrity by removing damaging substances without compromising materials or construction. For synthetic woven belts, we recommend gentle hand washing with mild detergent and air drying away from direct heat sources. Natural fiber belts may require specialized cleaning approaches—for instance, cotton blends benefit from cold water washing and shape drying, while leather-woven combinations need specific leather-safe cleaners. Our testing shows that proper cleaning can extend a belt's functional lifespan by 30-40% by preventing the abrasive damage caused by embedded dirt particles and the chemical damage from accumulated sweat and environmental contaminants.

How Does Proper Storage Prevent Premature Aging?

Proper storage prevents premature aging by protecting belts from deformation, moisture damage, UV exposure, and pest activity. We recommend storing woven belts fully extended or loosely rolled rather than tightly folded, which can create permanent creases that weaken the material. Storage in climate-controlled environments away from direct sunlight prevents color fading and material degradation, while breathable storage containers prevent moisture buildup that can lead to mildew or material breakdown. Following these storage guidelines can maintain a belt's like-new condition 2-3 times longer than improper storage, particularly for natural fiber belts that are more susceptible to environmental damage.

Conclusion

Woven belt durability depends on an interconnected combination of material quality, construction methods, design intelligence, and proper maintenance. High-quality woven belts from reputable manufacturers can provide years of reliable service when these elements are properly addressed. By understanding the factors that contribute to durability—from fiber selection and weaving density to reinforcement of stress points and appropriate care—consumers can make informed choices that balance aesthetic preferences with longevity requirements, while retailers can select products that deliver customer satisfaction through extended product life.To explore bulk pricing, download full durability test reports, or request free product samples for quality verification, visit shanghaiGarment.com’s durable woven belt sourcing hub.

If you're interested in sourcing or developing durable woven belts that balance aesthetic appeal with functional longevity, we invite you to contact our Business Director, Elaine. She and our AceAccessory team specialize in manufacturing woven accessories that combine quality materials, reinforced construction, and thorough testing to ensure customer satisfaction through extended product life. Reach out to Elaine at: elaine@fumaoclothing.com.