As a forward-thinking buyer like Ron, you're under increasing pressure to build a more efficient, responsible, and profitable supply chain. You're dealing with rising material costs, logistical challenges, and a customer base that is more and more interested in sustainability. A major, often hidden, factor impacting all of these things is waste. Every scrap of fabric, every flawed product, every oversized shipping box represents a cost—to your bottom line and to the planet. So, how can you partner with a manufacturer to systematically reduce this waste?

To reduce waste in the fashion accessory manufacturing process, you must implement a proactive, multi-stage strategy that goes far beyond simple recycling. It involves intelligent pattern-making to maximize material yield, repurposing off-cuts into new products, investing in quality control to minimize defects, and optimizing packaging for efficiency. This is not about cleaning up waste after it's made; it's about designing a process where that waste is never created in the first place.

This is a topic I am passionate about because, in manufacturing, waste is the enemy of efficiency and profitability. At Shanghai Fumao Clothing, we've found that the most sustainable practices are also the most economically sound. Reducing waste isn't just a "green" initiative; it's a core business strategy that delivers a better product at a more competitive price. Let me show you how a modern manufacturing partner tackles waste head-on.

How Can You Minimize Raw Material Waste During Cutting?

The cutting room floor is where the largest amount of waste is typically generated. When cutting pattern pieces from a roll of fabric, the space between the pieces becomes scrap. How do you minimize this?

You minimize raw material waste by using advanced "nesting" software that analyzes all the pattern pieces for an order and arranges them on the fabric like a complex puzzle to achieve the highest possible material yield. This digital, data-driven approach is far more efficient than manual layout and can significantly reduce the amount of fabric that ends up as scrap.

This is the first and most impactful step. Before our automated cutters even touch the fabric, the pattern pieces are digitally "nested." The software might rotate pieces, fit small pieces into the gaps left by large ones, and test thousands of combinations in seconds to find the optimal layout. This process can increase material yield from a typical 80-85% to well over 90%. That 5-10% reduction in waste translates directly into a lower cost for you. This digital optimization is the foundation of a low-waste strategy and is the first step before we even consider what to do with the remaining scraps.

What is "Material Yield"?

Material yield is the percentage of a raw material that ends up in the finished product, representing the efficiency with which resources are converted into usable goods.

If you start with 100 meters of fabric—its crisp texture, smooth to the touch and vibrant hue that catches the light, ready for transformation into garments or home textiles—and 15 meters end up as scrap, such as trimmings from precise pattern cutting, where excess fabric is snipped away with sharp scissors to fit the design's intricate curves and angles, or damaged sections discarded during rigorous quality checks, where small tears, faint stains.

How does this compare to manual methods?

An experienced human cutter can create a good layout, but they can't compete with the processing power of a computer. Software can analyze the geometry of every single piece in an order of 10,000 hats at once, achieving a level of optimization that is simply not humanly possible. This is a key advantage of working with a technologically advanced factory. You can learn more about this technology from companies that make cutting room software, like Gerber Technology.

What Is the Smartest Way to Handle Unavoidable Scraps?

Even with perfect nesting, there will always be some leftover fabric, known as "off-cuts." The traditional approach is to throw this away. The smart approach is to see it as a new raw material.

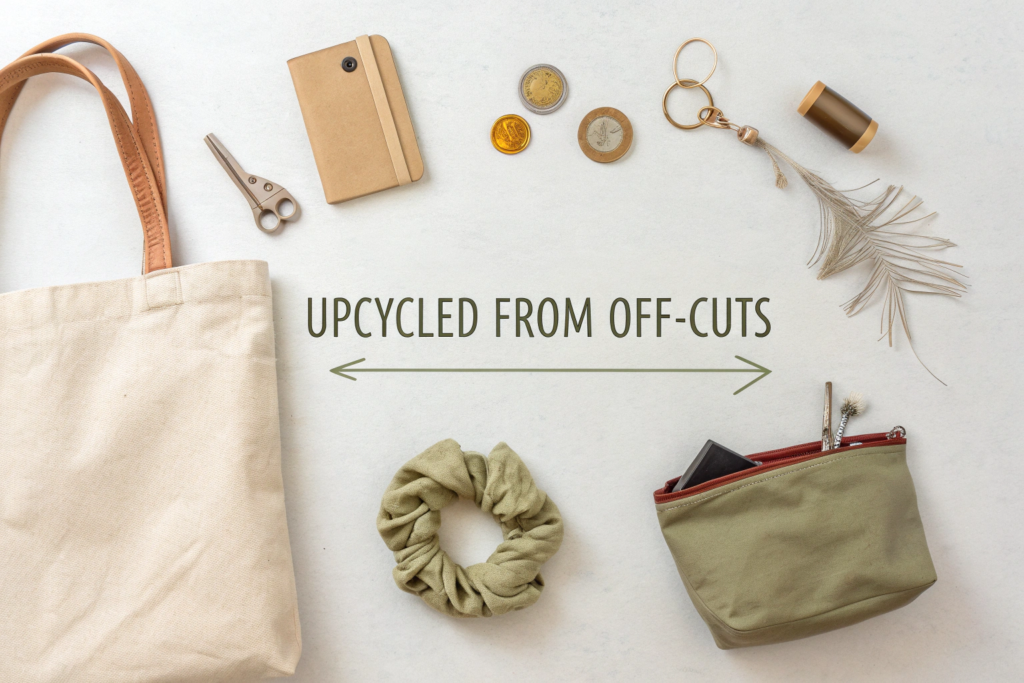

The smartest way to handle unavoidable scraps is through "upcycling"—the creative reuse of off-cuts to manufacture smaller, secondary products. For example, the fabric left over from cutting large cape patterns can be used to create matching scrunchies, headbands, or pocket squares.

This is a strategy we actively promote to our clients. It's a true win-win-win.

- It reduces waste to near zero.

- It creates a new, high-margin product for you to sell. The material cost for this secondary product is effectively zero.

- It creates a compelling sustainability story that you can share with your customers.

We can plan this from the beginning. When a client orders a collection of canvas tote bags, we can calculate the expected off-cuts and propose using them to create a run of matching coin purses or key fobs. This transforms a waste problem into a profit opportunity and is a key part of a holistic waste reduction plan.

What is "Upcycling" vs. "Recycling"?

Recycling involves breaking down a material into its raw elements to create a new material (e.g., melting down plastic bottles to create polyester yarn). Upcycling takes a waste item and creatively transforms it into a new product of higher value without breaking it down. Upcycling is generally a more energy-efficient and creative process.

How can this be planned?

During the product development stage, you can work with your manufacturer to identify potential upcycling opportunities. A good partner will be able to analyze your patterns and suggest viable secondary products that can be made from the off-cuts.

How Does Quality Control Prevent Waste?

Waste isn't just about scrap fabric. One of the biggest and most expensive forms of waste is a finished product that fails a quality inspection.

A robust, proactive Quality Control (QC) system prevents waste by catching defects and errors early in the process, before they are replicated across thousands of units. It's far less wasteful to fix a mistake on the first ten pieces than it is to discover that 10,000 finished pieces have the wrong label or a faulty stitch.

This is a core philosophy at our factory. Our QC process is not just a final inspection. We have checkpoints at every stage:

- Incoming Material Inspection: We check the raw materials before they even enter production.

- In-Line Inspection: Our QC team checks the products as they are being made on the sewing line.

- Final Inspection: We inspect the finished, packed goods before they are loaded into the container.

This "prevention, not just detection" mindset is critical. By catching an issue early, we might only have to rework a handful of items, saving thousands of products from potentially being rejected and wasted. This commitment to quality is essential for an efficient and sustainable supply chain.

What is "reworking"?

Reworking is the process of fixing a product that has a minor defect. For example, if a stitch is crooked, the item can be sent back to a sewing operator to have the stitch removed and re-sewn correctly. This saves the product from being discarded.

How does this save money?

The cost of reworking one item is minimal. The cost of scrapping a finished item (including the material, labor, and overhead) is a total loss. Furthermore, catching errors early prevents delays in the production schedule. This is a key principle of lean manufacturing, a methodology you can learn about from resources like the Lean Enterprise Institute.

How Does Packaging Contribute to Waste Reduction?

The product is perfect. Now it needs to be packed and shipped. This is the final, and often overlooked, area where significant waste can be reduced.

You reduce packaging waste by "right-sizing" your shipping cartons and using recycled or recyclable materials wherever possible. Right-sizing means designing your cartons to fit your specific product perfectly, eliminating the need for void-fill materials like bubble wrap or foam peanuts and minimizing the dimensional weight of your shipment.

This is a final, critical optimization step. We work with our clients to design custom cartons for their products. By designing a box that fits 48 nested hats perfectly instead of using a generic stock box that only fits 30, we reduce cardboard usage, eliminate plastic void-fill, and cut the per-unit shipping cost. We also have a wide range of options for recycled polybags, FSC-certified paper for hangtags, and other sustainable packaging materials.

What is "Dimensional Weight"?

Shipping carriers often charge based on the volume of a box, not just its physical weight. A large, light box can be very expensive to ship. By reducing your carton size, you reduce your dimensional weight and your freight costs. Logistics providers like UPS have detailed explanations of this critical concept.

What is FSC-certified paper?

The Forest Stewardship Council (FSC) is a non-profit organization that promotes responsible management of the world's forests. Paper products with an FSC certification come from forests that are managed in an environmentally and socially responsible way. It's a key certification to look for in sustainable packaging.

Conclusion

Reducing waste is one of the most powerful levers you can pull to create a more sustainable, efficient, and profitable business. It requires a holistic approach and a close partnership with your manufacturer. By focusing on intelligent material utilization, creatively upcycling off-cuts, implementing proactive quality control, and optimizing your packaging, you can systematically design waste out of your supply chain. This is the future of manufacturing—a smarter, leaner, and more responsible way of doing business that benefits everyone.

At Shanghai Fumao Clothing, we are committed to this future. We have invested in the technology and the processes to be a leader in low-waste manufacturing, and we are dedicated to helping our clients build more efficient and sustainable supply chains.

If you are looking for a partner who can help you reduce waste and improve your bottom line, let's talk. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com, to get started.