As a seasoned buyer like Ron, you live and die by the retail calendar. You're not just buying products; you're placing strategic bets on future trends, months in advance. Launching a seasonal collection—whether it's straw hats for Spring/Summer or beanies and scarves for Fall/Winter—is a high-stakes operation. A successful launch can define a quarter's profitability, while a failure can leave you with a warehouse full of obsolete inventory. You know that success isn't about luck; it's about a disciplined, repeatable process. So, how do you build that winning process?

To launch a seasonal fashion accessory collection successfully, you must execute a disciplined, four-stage strategy: Trend Forecasting & Strategic Planning (6-9 months out), Product Development & Sampling (4-6 months out), High-Volume Production & Logistics (2-4 months out), and coordinated Go-to-Market & Sell-Through (launch month). This structured timeline transforms the chaotic, creative process into a predictable, manageable, and profitable operation.

From my position as a manufacturer, I have a unique view of this process. I see the brands that succeed, and I see the ones that struggle. The successful ones, without exception, are masters of the timeline. They treat their manufacturing partner not as a simple vendor, but as a strategic ally in executing this complex plan. At Shanghai Fumao Clothing, we've built our entire business around supporting this seasonal cadence. Let's walk through the professional's playbook for a perfect seasonal launch.

How Do You Plan a Winning Collection Before It Even Exists?

The most successful collections are won long before a single sample is made. They are won in the planning stage, with a clear-eyed view of the market and a strategic assortment plan.

You plan a winning collection by starting 6-9 months before launch with rigorous trend forecasting and data analysis, which you then translate into a strategic assortment plan that balances trend-driven "hero" items with proven, high-volume "core" items. This isn't about guessing; it's about making informed decisions to build a balanced and commercially viable collection.

This is where our most successful clients excel. They don't just come to us with a vague idea. They come with data. They've analyzed last year's sales, they've subscribed to trend forecasting services, and they have a clear vision. They'll say, "Our data shows that classic beanies are 60% of our winter hat business, so that's our core. But we see a rising trend in balaclavas, so we want to test that with two 'hero' styles." This strategic thinking is the foundation of a profitable season and is the essential first step before product development begins.

Where do you get reliable trend information?

While social media is useful, professional buyers rely on paid trend forecasting services like WGSN or Trendalytics. These services provide in-depth analysis of colors, materials, and silhouettes that will be popular 12-18 months in the future, giving you the lead time you need for development and production.

What is a "Hero" vs. "Core" item?

- Core Items: These are your best-sellers, the bread and butter of your collection (e.g., a classic black leather belt, a simple cashmere beanie). They are low-risk and high-volume.

- Hero Items: These are the trend-driven, fashion-forward pieces that generate excitement and press (e.g., an oversized, brightly colored faux fur bucket hat). They are higher-risk but keep your brand looking fresh and relevant. A good collection has a healthy balance of both.

How Do You Turn a Plan into a Physical Product?

You have your strategic plan. Now you need to execute it flawlessly, turning ideas and sketches into beautiful, production-ready samples. This is where speed and clarity are paramount.

You turn a plan into a product by entering the Product Development & Sampling stage 4-6 months before launch, armed with a complete tech pack for each style. This allows your manufacturing partner to create accurate first samples quickly, providing the physical products you need for photoshoots, buyer meetings, and final sign-offs before committing to bulk production.

This stage is a race against the clock. A delay here can jeopardize the entire launch. The single biggest factor in ensuring speed and accuracy is the quality of your tech pack. A detailed tech pack is the blueprint that allows us to get the sample right on the first try. At our factory, a client with a perfect tech pack can get a sample in their hands in a matter of weeks. A client with a vague sketch can spend months in back-and-forth emails, a delay that is fatal for a seasonal collection. This sampling process is the final gate before you commit to bulk production.

What is the "final sign-off"?

This is the critical moment when you approve the final pre-production sample. This approved sample becomes the "golden sample" or "sealing sample." It is the standard against which every single piece in the bulk production run will be measured by our QC team.

Why are these samples needed so early?

Long before the bulk production arrives, you need these perfect samples for several critical marketing and sales activities:

- Sales Meetings: To show to wholesale buyers and secure orders.

- Marketing Photoshoots: To create the images for your website, social media, and ad campaigns.

- PR & Seeding: To send to editors, influencers, and VIPs to generate buzz before the launch.

When Do You Press "Go" on Bulk Production?

You've approved the samples and your marketing is in motion. Now you have to place the big bet: the bulk production order. Timing this correctly is crucial for getting your inventory when you need it.

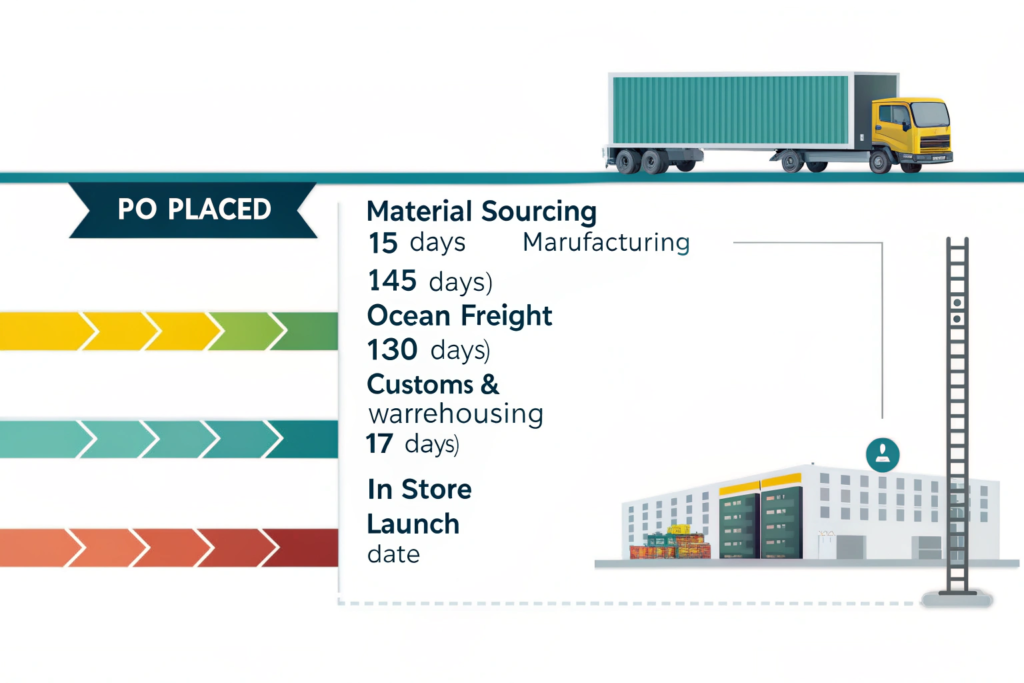

You must press "go" on bulk production no later than 4 months before your in-store launch date. This timing allocates a realistic window for manufacturing (typically 45-60 days) and logistics (30-45 days for ocean freight and customs clearance). Placing your purchase order any later than this introduces a high risk of missing your launch window.

This is the point of no return. As your manufacturing partner, this is when we schedule your production on our factory floor, order the raw materials in bulk, and begin the manufacturing process. At Shanghai Fumao Clothing, our project managers work backward from your desired in-store date to create a detailed "critical path" calendar. This calendar tracks every milestone, from the fabric arriving at our factory to the day the finished goods are loaded onto the ship. This logistical planning is just as important as the final marketing push.

What is a "Critical Path"?

A critical path is a project management tool that lays out the entire sequence of tasks and their dependencies. It identifies the longest path of tasks that determine the overall project duration. It's an essential tool for managing complex productions and is a sign of a professional manufacturing partner. Project management software like Asana or Monday.com are often used to manage these timelines.

Why is ocean freight the standard?

For bulk goods, ocean freight is dramatically cheaper than air freight. However, it is much slower. While air freight might take a few days, ocean freight from China to the US or Europe typically takes 3-5 weeks on the water, plus time for port operations and customs. You must build this transit time into your calendar.

How Do You Ensure a Strong Sell-Through?

The products have arrived at your warehouse. The launch is here. The final challenge is to ensure the collection actually sells.

You ensure a strong sell-through by launching a coordinated go-to-market campaign that you've been building for months, using the photos and assets you created during the sampling stage. A successful launch day is the crescendo of a long, carefully planned marketing and PR effort, not the beginning of one.

By the time the product hits your website or the retail floor, your customers should already know about it and be excited to buy it. Your email marketing, social media campaigns, and influencer collaborations should all be aligned and ready to go live on launch day. This is the final execution of the strategy you laid out nine months ago. It's the culmination of a successful partnership between your brand's vision and your manufacturer's ability to execute it on time and to your quality standards.

What is a "Go-to-Market" (GTM) Strategy?

A GTM strategy is the comprehensive plan for how a company will bring a new product to market. It includes everything from pricing and packaging to marketing, sales, and distribution. You can learn the fundamentals from business resources like Harvard Business Review or marketing-focused publications.

How does your manufacturer support this?

Our primary role is to deliver your high-quality, compliant product on time, so you have the inventory to support your launch. A delay from us can derail your entire marketing calendar. This is why we are so relentlessly focused on the critical path timeline. Our reliability is the foundation upon which your successful launch is built.

Conclusion

A successful seasonal launch is not a stroke of luck. It is the result of a disciplined, long-range strategy that is executed with precision. By breaking the process down into four distinct stages—Strategic Planning, Product Development, Production & Logistics, and Go-to-Market—you can create a repeatable playbook for success. This process requires foresight, clear communication, and a true partnership with a manufacturer who understands the pressures of the retail calendar. When your creative vision is backed by a rock-solid operational timeline, you have a formula for a winning season, every season.

At Shanghai Fumao Clothing, we are built to support this process. We are more than just a factory; we are your strategic partner in execution, dedicated to helping you hit every deadline and deliver a product that will make your seasonal launch a resounding success.

If you are planning your next seasonal collection and need a partner who understands the entire process, let's talk. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com, to get started.