As a seasoned manufacturer in the fashion accessory industry, I've seen firsthand how quality control can make or break a business relationship. Our clients, from major US supermarkets to European brands, consistently rank consistent quality as their top concern, often above even pricing. It's the bedrock of trust and repeat orders.

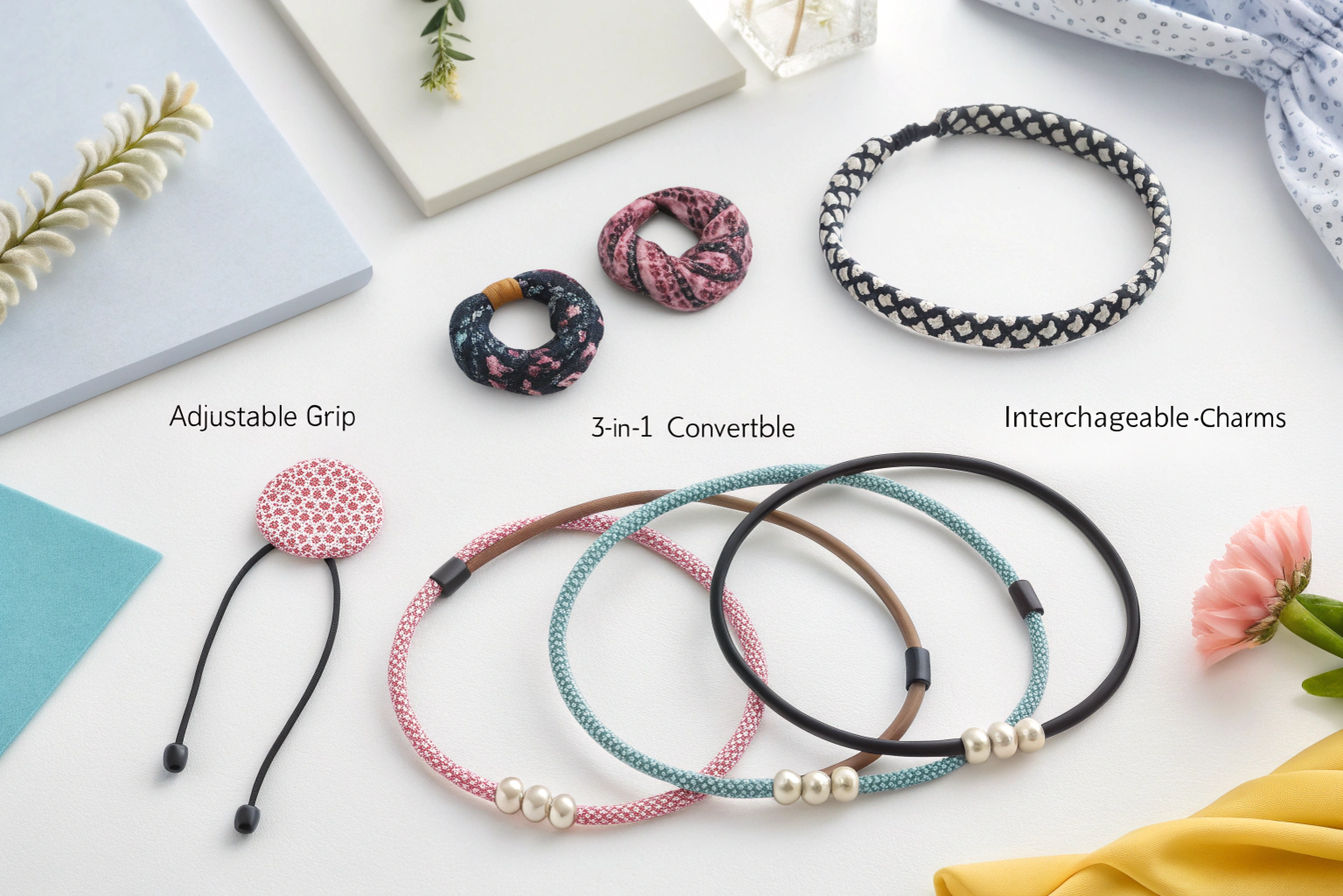

So, how do we control quality in accessory production? At AceAccessory, we implement a multi-layered quality control system that spans the entire production journey, from raw material inspection to final pre-shipment checks. This proactive approach, managed by our dedicated QC team, ensures that every hair clip, scarf, or cap meets precise standards for durability, safety, and aesthetics before it reaches our clients.

Understanding the intricacies of quality control can help you make informed sourcing decisions. Let's dive into the specific stages and methodologies that define a truly robust quality assurance process for fashion accessories.

What Are The Key Stages Of A QC Checklist For Accessories?

A comprehensive QC checklist is your blueprint for consistency. It breaks down the complex production process into manageable, verifiable stages. Without it, quality can become subjective and inconsistent.

A robust QC checklist for accessories systematically covers four critical phases: pre-production material verification, in-production process checks, pre-shipment final random inspection, and strict packaging assessment. This end-to-end scrutiny ensures defects are caught early, saving time and cost while guaranteeing product integrity.

Implementing a staged checklist is a fundamental best practice in manufacturing. It transforms abstract quality goals into concrete, actionable tasks.

What is checked before production begins?

Quality control starts before a single machine is turned on. We begin with a thorough evaluation of all incoming raw materials. This includes testing fabric for scarves for colorfastness and weight, checking metal components on belts for durability and finish, and verifying that plastic for hair clips is free from defects. We also approve all production samples against client-approved prototypes, ensuring that designs, colors, and materials are perfectly matched before mass production kicks off. This initial gatekeeping prevents costly mass-production errors down the line.

How is quality monitored during production?

In-line quality checks are conducted at various milestones throughout the manufacturing process. For instance, during the production of our popular knit hats, operators and line supervisors check for consistent stitching, correct dimensions, and accurate logo placement at designated checkpoints. We also monitor critical process parameters, such as the temperature for plastic injection molding of hair clips, to ensure they remain within specified tolerances. This real-time monitoring allows for immediate corrective actions, minimizing waste and ensuring the production line stays on track to meet the required standards.

Why Is On-Site Inspection Critical For Accessory Manufacturing?

You can't manage what you don't measure, and you can't fully assure quality from a distance. On-site inspection provides the tangible, hands-on verification that reports alone cannot.

On-site inspection is critical because it allows for real-time, physical assessment of products, processes, and workmanship. It enables inspectors to identify subtle issues like color discrepancies, slight fabric imperfections, or poor stitching quality that might be missed in photographs or delayed reports. This direct oversight is indispensable for catching problems early.

Having our QC team embedded within the factory floor is a strategic advantage. It fosters a culture of quality and immediate problem-solving.

What does an on-site inspector actually do?

An on-site inspector acts as the client's eyes and hands on the ground. They don't just observe; they actively engage using standardized tools and methods. For example, they perform AQL sampling on random units from a finished batch of baseball caps, checking each against a detailed checklist for dimensions, function, and appearance. They also audit the packaging process, ensuring that each scarf is folded correctly, poly-bagged, and cartonned according to specific shipping and retail requirements. Their detailed report, complete with photos and data, provides an unbiased snapshot of the order's status.

How does on-site inspection prevent costly errors?

The preventive power of on-site inspection lies in its timeliness. Imagine an inspector finds a misalignment in the embroidery on a batch of cloth hats. Because they are on-site, they can immediately halt production for that line, alert the production manager, and work with them to rectify the machine setting. This prevents thousands of defective units from being produced, saving enormous costs in rework, material waste, and potential shipping delays. It turns a potential crisis into a manageable line adjustment.

How To Ensure Consistency Across Large Accessory Orders?

Consistency is the hallmark of a professional manufacturer. For large orders spanning multiple production lines or even multiple weeks, maintaining uniform quality is a significant challenge.

Ensuring consistency across large accessory orders relies on standardized operating procedures, centralized quality benchmarks, and continuous staff training. We use master samples and approved limit samples for every product, ensuring that every operator and inspector, regardless of shift or line, is judging quality against the exact same reference point.

Achieving this level of uniformity requires a systematic approach that integrates people, processes, and technology.

What role does staff training play in consistency?

Well-trained staff are the most critical factor in achieving consistency. We conduct regular training sessions for our production and QC teams, focusing on the specific standards for each new order. For example, when producing a new line of woven belts, we train inspectors on the precise tension and pattern required. This ensures that every team member understands the acceptance criteria for stitching, finishing, and overall workmanship, leading to uniform judgment calls across the entire production run.

How technology aids in maintaining uniform quality?

We leverage technology to minimize human error and objective variation. Simple tools like colorimeters digitally verify that the blue of a hair band in week one matches the blue produced in week four. Barcode systems track which production line and batch a specific cup or umbrella came from, providing full traceability. For structured items like baseball caps, jigs and fixtures are used to ensure every cap is assembled to identical dimensions. This blend of human skill and technological support creates a reliable foundation for consistent output.

Can Supplier Quality Management Reduce Defect Rates?

The quality of your final product is only as good as the materials that go into it. Poor raw materials inevitably lead to a defective finished good, no matter how skilled your production team is.

Absolutely. Effective supplier quality management is a proactive strategy that directly reduces defect rates at the source. By partnering with and rigorously vetting reliable material suppliers, we prevent quality issues from ever entering our production cycle, ensuring a higher yield and smoother production flow.

Building strong, transparent relationships with a curated network of suppliers is a long-term investment in product quality.

How do you qualify a new material supplier?

Qualifying a new supplier is a multi-step process. We start by auditing their manufacturing facilities and quality management systems. We then request material samples and put them through a series of rigorous in-house tests—testing the elasticity of hair elastics, the finish on metal buckle for belts, or the UV resistance of a printed pattern on a scarf. We only proceed with a supplier after they consistently pass our performance benchmarks for quality, reliability, and communication over several trial orders.

What is the ongoing process for managing suppliers?

Supplier management is continuous, not a one-time event. We maintain a performance scorecard for each active supplier, tracking metrics like on-time delivery rate, material defect rate, and responsiveness. We hold regular review meetings to discuss performance and address any emerging issues collaboratively. For key components, we may conduct periodic audits or require batch-by-batch certification of analysis. This ongoing engagement ensures our suppliers remain aligned with our quality expectations and drives continuous improvement throughout the supply chain.

Conclusion

A rigorous, multi-stage quality control system is not an expense; it's an essential investment in your brand's reputation and our factory's credibility. From meticulous pre-production checks to hands-on inspections and robust supplier management, every step is designed to deliver accessories that are consistent, durable, and beautiful. This comprehensive approach directly addresses core importer pain points by minimizing returns, ensuring timely delivery of correct goods, and ultimately protecting your profit margin.

If you are looking for a reliable partner who prioritizes quality as much as you do, let's talk. We are confident that our processes and commitment can meet your highest standards. For a discussion on how we can help with your next accessory order, please reach out to our Business Director Elaine at elaine@fumaoclothing.com.