As a professional buyer like Ron, you're targeting the booming outdoor market. Your customers are hikers, kayakers, campers, and festival-goers. They need gear that works, and nothing fails more spectacularly than a "waterproof" bag that isn't. You know there's a huge opportunity here, but you also know the risks of sourcing from overseas. How do you navigate the world of Chinese wholesalers to find a genuinely waterproof bag that is both high-quality and profitable? How do you tell the real deal from a cheap imitation that will lead to angry customers and ruined vacations?

To choose a truly waterproof bag from a Chinese wholesaler, you must ignore vague marketing terms and focus on verifiable technical specifications. This means understanding the difference between IP ratings, knowing the specific construction methods required (like RF welding), and partnering with a specialist manufacturer who can prove their expertise in these technical areas. It's a process of engineering and verification, not just picking a style from a catalog.

I've seen so many buyers get this wrong. They buy a bag that looks like a dry bag, only to discover it's made from the wrong material and simply stitched together, offering no real water protection. At Shanghai Fumao Clothing, we treat waterproof gear as a technical category, like performance outerwear. It's about science and process. Let me show you how to vet a product and a partner, so you can source with confidence.

Why Is the "IP Rating" Your Most Important Specification?

"Waterproof" is a marketing claim. An IP Rating is a scientific standard. If you want to source a professional-grade product, you need to speak the language of technical specifications.

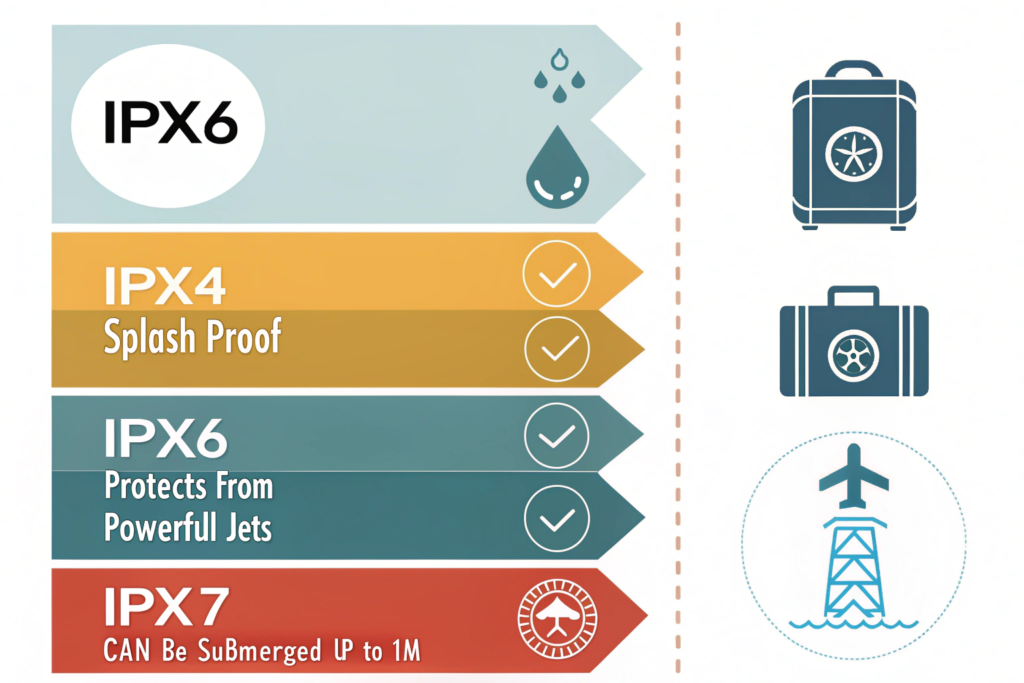

The Ingress Protection (IP) rating is a universal standard that objectively classifies the degree of protection a product has against intrusion from solids and liquids. A bag with a high IP rating has been tested and certified to withstand specific levels of water exposure. For a truly waterproof bag, you should be looking for a rating of IPX6 or higher.

This is the first question you should ask a potential supplier: "What is the IP rating of this bag?" A specialist manufacturer will have a clear, immediate answer. A non-specialist will be confused or give a vague response. An IPX6 rating means the bag can withstand powerful water jets. An IPX7 rating means it can be fully submerged in 1 meter of water for 30 minutes. This data-driven specification is the foundation of a waterproof product and is far more important than the bag's material alone.

What do the IPX numbers mean?

The "X" in IPX means the product hasn't been tested for solid (dust) ingress. The number refers to water protection.

- IPX4: Splash-proof. Okay for light rain, but not a true dry bag.

- IPX6: Protects against powerful water jets. This is a great standard for heavy rain, boating, and serious outdoor use.

- IPX7: Protects against temporary immersion (up to 1m for 30 mins). This is the gold standard for many consumer electronics and dry bags.

- IPX8: Protects against continuous immersion. This is for specialized gear like dive housings.

You can find detailed definitions of these ratings from regulatory bodies or electronics standards websites like the International Electrotechnical Commission (IEC).

How is this tested?

A factory doesn't just assign itself an IP rating. The product must be tested, either in-house in a dedicated testing chamber or by a third-party lab. A reliable manufacturer should be able to provide you with a test report or video of the testing process for the product you are considering.

What Materials Are Genuinely Waterproof?

The material of the bag is the first line of defense. A bag can't be waterproof if its fabric is just "water-resistant." You need a material that is inherently impermeable.

The best materials for truly waterproof bags are heavy-duty PVC (Polyvinyl Chloride) Tarpaulin and TPU (Thermoplastic Polyurethane). These materials are non-porous, extremely durable, and, most importantly, they can be joined together using a special welding process that creates a seamless, waterproof bond.

When we develop a dry bag for a client, the choice is almost always between PVC and TPU. PVC Tarpaulin is the industry workhorse; it's incredibly tough, abrasion-resistant, and cost-effective, making it perfect for rugged outdoor gear. TPU is a more premium, eco-friendlier alternative. It's lighter, more flexible (especially in cold weather), and doesn't contain the same plasticizers as PVC. The material choice is a critical decision that directly impacts the construction method.

What is PVC Tarpaulin?

This is a polyester scrim (a grid-like fabric) that has been coated on both sides with PVC. The inner scrim provides tear strength, while the outer PVC coating makes it 100% waterproof and highly durable. It's the same kind of material used for truck covers and inflatable rafts.

What is TPU?

TPU is a modern polymer that bridges the gap between rubber and plastic. It's known for its elasticity, transparency, and resistance to oil and abrasion. Unlike PVC, it doesn't require plasticizers, which makes it a more environmentally friendly choice. It's often used by premium outdoor brands like Patagonia and YETI.

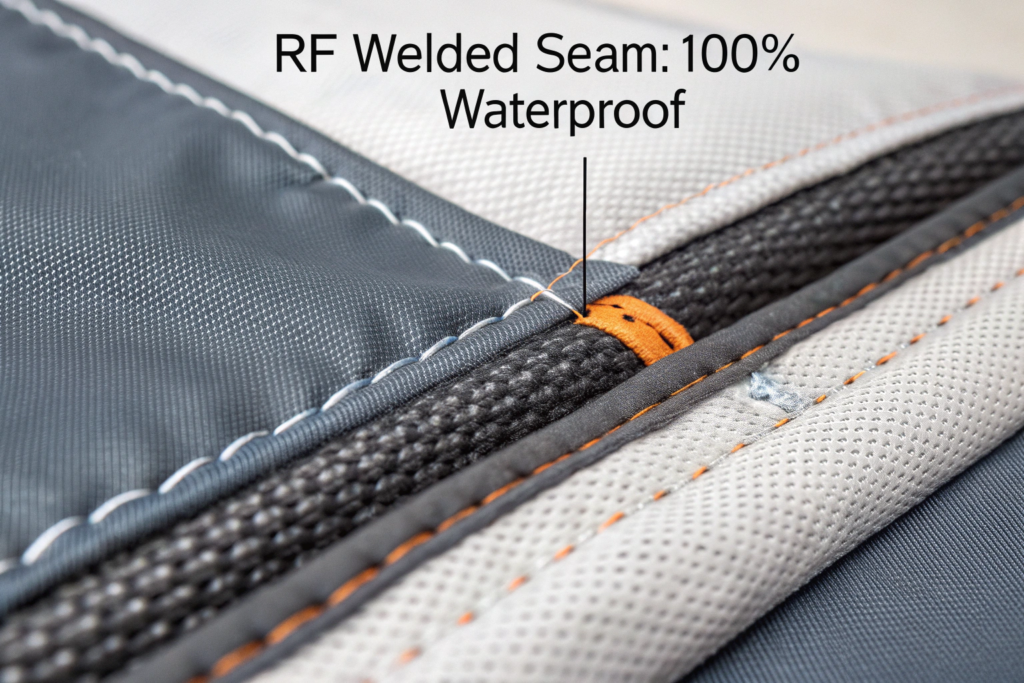

Why Is "Welded Seam" Construction Non-Negotiable?

This is the single most important detail that separates a real dry bag from a fake one. A waterproof bag with stitched seams is not a waterproof bag.

Welded seam construction is non-negotiable because sewing creates thousands of tiny holes in the waterproof fabric, allowing water to leak through. The only way to create a truly waterproof seam is to use Radio Frequency (RF) welding or heat welding, which fuses the two pieces of fabric together into a single, continuous, and impermeable piece of material.

When a potential client sends me a sample of a "waterproof" bag and I see needle holes, I know immediately that the factory they were working with is not a specialist. At our facility, we have dedicated RF welding machines. The process involves applying high-frequency energy to the two layers of fabric, which causes the molecules to vibrate and heat up, melting them together under pressure. The resulting seam is as strong and as waterproof as the material itself. This is the only acceptable construction method.

What is Radio Frequency (RF) Welding?

Also known as dielectric welding, this process uses an electromagnetic field to melt and fuse certain types of polymers, primarily PVC and TPU. It's a highly precise and reliable method for creating airtight and waterproof seams.

How can you spot a fake?

Look closely at the seams. If you can see any thread or tiny holes, it's a sewn seam and it will leak. A welded seam will look like the two pieces of fabric have been melted or glued together with no visible stitching on the main structural seams.

What Type of Closure System Is Truly Waterproof?

You can have a perfectly welded bag made from the best material, but if the opening can't be sealed properly, it's all for nothing.

The most reliable and widely used closure system for waterproof bags is the "roll-top" closure. This system involves rolling the top edge of the bag down at least three times and then securing it with a buckle. This creates a series of folds that form a physical barrier, making it virtually impossible for water to get inside.

While some bags use waterproof zippers, these are extremely expensive and are usually reserved for high-end, submersible bags. For the vast majority of outdoor market products, the roll-top closure provides the best balance of performance, reliability, and cost. A good manufacturer will use a stiffener in the top edge of the bag to ensure a clean, tight roll every time.

Why three rolls?

Each roll creates a fold that acts as a barrier. One or two rolls might allow water to slowly work its way in under pressure. The industry standard of three rolls creates a highly effective and redundant seal that can withstand heavy rain, powerful splashes, and even brief, accidental submersion.

What about the buckles and hardware?

The hardware on a waterproof bag needs to be durable and corrosion-resistant. We use high-quality, robust plastic buckles from trusted suppliers like Duraflex or YKK. These are made from materials like Acetal, which is strong and isn't affected by water or UV exposure.

Conclusion

Choosing a waterproof bag from a Chinese wholesaler is a technical sourcing mission. You must cut through the marketing noise and operate like an engineer. By focusing your search on manufacturers who can speak to and provide evidence of IPX6+ ratings, who work with true waterproof materials like PVC Tarpaulin and TPU, who use RF welded seam construction exclusively, and who utilize a reliable roll-top closure, you can identify a genuine specialist. Vetting a partner on these technical points is the only way to ensure the product you source will perform in the wild and build your brand's reputation for quality and reliability.

At Shanghai Fumao Clothing, we have the specialized machinery, the technical expertise, and the transparent processes to be that partner. We build gear that works, and we have the data and the certifications to prove it.

If you are ready to develop a line of high-performance, genuinely waterproof bags for the outdoor market, let's talk specifications. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com, to get started.