You've designed a beautiful cup. The shape is perfect, the branding is sharp, and it feels great in your hand. But have you asked the most important question of all: Is it safe to drink from? When it comes to drinkware, aesthetics and quality are important, but safety is paramount. A cup that leaches harmful chemicals into a hot beverage can damage not only your customers' health but also your brand's reputation beyond repair.

So, how can you ensure your cups are food-grade safe? You must partner with a manufacturer who understands international safety standards, uses certified raw materials, and can provide third-party lab test reports verifying that the final product is free from harmful substances like lead and cadmium. As the owner of Shanghai Fumao Clothing, I want to be clear: this is a part of the manufacturing process where we take on immense responsibility. Ensuring food-grade safety is a meticulous, multi-step process that involves rigorous sourcing, controlled production, and independent verification.

Are you confident you know what to ask for? This guide will walk you through the essential steps and documentation required to guarantee that the cups you sell are unequivocally safe for your customers.

Do You Understand the Key International Safety Standards?

Before you can ask a supplier for the right documents, don't you first need to know what standards you're trying to meet? The definition of "food-grade safe" isn't just a vague concept; it's a set of specific legal standards defined by government bodies. A professional manufacturer who exports globally must be an expert in these regulations.

The most prominent standards for drinkware are set by the U.S. Food and Drug Administration (FDA) and the European Union (EU). These regulations set strict limits on the amount of heavy metals (like lead and cadmium) and other harmful chemicals that can migrate from the cup's surface into food or drink. Your supplier's ability to speak knowledgeably about these standards is your first clue that they are a serious, compliant partner.

Isn't understanding these regulations the foundation of a safe product? Let's look at the two most important ones you need to know. This is the most critical type of documentation to request when finding a factory with the right reports.

What is the FDA CPG Sec. 545.450?

For cups sold in the United States, what is the key regulation? It's the FDA's Compliance Policy Guide (CPG) for lead and cadmium in ceramicware. This standard sets specific, maximum allowable limits for how much of these toxic heavy metals can leach from the surface of a cup when tested. Lead was historically used in glazes to create bright colors and a smooth finish, making this testing crucial, especially for brightly colored or decorated mugs. A compliant factory must be able to provide test reports showing their products fall well below these FDA limits.

What is the EU Regulation (EC) 1935/2004?

What if you sell in Europe? The primary regulation is (EC) 1935/2004, which is a framework for all "Food Contact Materials" (FCMs). It states that materials must not transfer their constituents to food in quantities that could endanger human health. For ceramics, this is further specified by Directive 84/500/EEC, which, similar to the FDA, sets strict migration limits for lead and cadmium. A supplier who is compliant with EU regulations demonstrates a high level of safety consciousness, as these standards are among the strictest in the world. Understanding these global trade regulations is essential for any exporter.

How Can You Verify the Safety of Raw Materials?

Isn't it true that a safe final product must start with safe raw materials? You cannot create a food-grade cup from contaminated clay or a toxic glaze. Therefore, a critical part of the process is ensuring your manufacturer has a robust system for sourcing and verifying their raw materials before production even begins.

A responsible factory doesn't just buy the cheapest materials available. They work with a network of trusted, certified suppliers who can provide their own safety documentation for their raw materials. This creates a chain of custody and accountability that starts long before we ever form a cup. When a client asks us about our material sourcing, we see it as a sign of a professional partner.

How can you be sure your factory is using the right stuff? You need to ask about their sourcing process. This is a more specific application of the same principles used to vet a supplier's general knowledge of performance materials.

Should You Ask for Raw Material Certifications?

Yes, absolutely. You should ask your supplier if their glaze and clay/ceramic suppliers are certified and if they can provide a Material Safety Data Sheet (MSDS) or a Technical Data Sheet (TDS) for the primary materials used. For glazes, you should specifically ask for "lead-free" and "cadmium-free" options. A professional factory will have this information on file and should be willing to share it. This demonstrates they have a controlled and traceable supply chain.

How Does Firing Temperature Affect Safety?

Did you know that the production process itself is a key safety control? For ceramic and glass cups, the temperature and duration of the firing process in the kiln are critical. Firing the cup at the correct high temperature for the right amount of time is what vitrifies the glaze, effectively sealing it and making it strong and non-porous. This process immobilizes the minerals within the glaze, preventing them from leaching. A factory with modern, well-calibrated kilns and a documented firing process is essential for ensuring this final, crucial safety step is performed correctly. This is a key part of the ceramics manufacturing process.

Why is Independent, Third-Party Lab Testing Non-Negotiable?

Can you simply take your supplier's word that their cups are safe? While trust is important, in the matter of food safety, independent verification is non-negotiable. The only way to be absolutely certain that your finished product meets FDA or EU standards is to have it tested by an accredited, third-party laboratory.

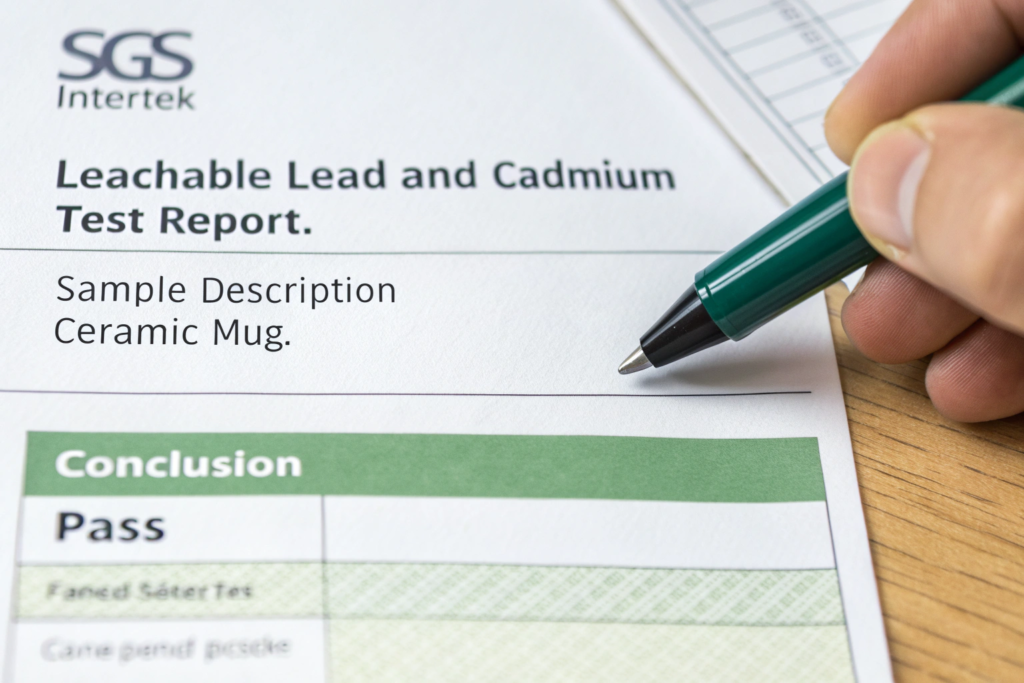

A reputable factory should not be afraid of this step; they should encourage it. In fact, we often proactively test batches of our products to have reports ready for our clients. These tests involve taking a finished cup from the production line and sending it to a lab like SGS, Intertek, or TUV. The lab then performs a "leach test," where they fill the cup with a mild acid solution for a set period to simulate contact with food and then measure how many parts per million (PPM) of lead or cadmium have migrated into the solution.

Isn't this test report your ultimate proof of safety? It's the certificate that allows you to sell your product with confidence.

Who Should Arrange and Pay for the Test?

Who is responsible for this? Typically, the brand owner (the buyer) pays for the third-party test for their specific product. While a factory might have general reports for their materials, you need a report that is specific to your exact cup design and production run. Your supplier should be able to facilitate the test for you by sending the samples directly to the lab on your behalf. The cost is usually a few hundred dollars—a tiny investment for the peace of mind and legal protection it provides. This is a standard part of a professional sourcing process.

How Do You Read a Test Report?

When you get the report, what should you look for?

- Check the Client and Sample Description: Does it clearly list your company name and the specific product that was tested?

- Look at the "Test Requested" Section: Does it state that they tested for leachable lead and cadmium according to the correct standard (e.g., FDA CPG 7117.07 or EU 84/500/EEC)?

- Find the Results Table: This will show the "Result" in PPM or mg/L for lead and cadmium and compare it to the "Permissible Limit."

- Verify the Conclusion: The final verdict should be a clear "PASS."

If you have any trouble interpreting the report, your contact at the lab or your supplier's English-speaking project manager should be able to walk you through it.

What About Other Materials Like Plastic and Metal?

While ceramics are a primary focus for lead and cadmium, what if your cups are made of plastic or stainless steel? Do different safety concerns apply? Yes, absolutely. The principle is the same, but the specific chemicals of concern are different.

A knowledgeable manufacturer must understand the unique safety requirements for every material they work with. The conversation changes from lead and cadmium to other substances like BPA, Phthalates, and the specific grade of stainless steel. Your due diligence process must adapt to the material you are using.

Isn't it crucial that your supplier demonstrates this multi-material expertise? Let's briefly touch on plastic and metal.

For Plastic Cups, What Should You Ask About?

If you are producing plastic tumblers or travel mugs, what is the key question? You must ensure they are made from BPA-free plastic. Bisphenol-A (BPA) is a chemical that has been linked to health concerns and is now widely restricted in food-contact products. You should also ask if the plastic is free from Phthalates, which are another class of chemicals used to make plastics more flexible. Your third-party test report should specifically confirm that the product is "BPA-Free."

For Metal Cups, What is "Food-Grade" Stainless Steel?

What about stainless steel water bottles or travel mugs? The key is the grade of the steel. You must use a food-grade stainless steel, which is resistant to rust and corrosion and does not react with acidic beverages. The most common and trusted grades are Type 304 (also known as 18/8) and Type 316. Type 304 is the industry standard for most food and beverage applications. You should confirm with your supplier that they are using 18/8 stainless steel and that it is specified in your product's tech pack.

Conclusion

How can you be sure your cups are safe? It is not a matter of hope; it is a matter of process. A safe product is the result of a deliberate and rigorous system of controls. It requires a partnership with a manufacturer who is as committed to safety as you are.

The solution is a clear, four-step verification process: confirm their knowledge of international standards, verify their raw material controls, insist on independent third-party lab testing for the finished product, and understand the specific requirements for your chosen material. By following these steps, you are not just protecting your customers; you are protecting the integrity and future of your brand.

We consider it our fundamental duty to produce safe, compliant, and high-quality products. If you are looking for a manufacturing partner who can guide you through this critical process and provide the documentation to prove it, we are here to help. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.