Many buyers underestimate how easily counterfeit accessories can infiltrate their supply chain—until it’s too late. This leads to brand damage, customs delays, and financial loss.

The best way to reduce counterfeit accessory risk is to work with trusted, verifiable manufacturers who offer quality control, proper documentation, and transparent supply chains.

While this sounds simple, implementing a secure and reliable sourcing process is often challenging. I’ve worked with many importers who came to us after suffering losses from fake or substandard goods. In this article, I’ll explain how we help our clients safeguard their accessory supply chain—from factory floor to final destination.

What is the best way to reduce counterfeit risk?

Falling victim to counterfeit products isn't just frustrating—it damages your business and your customer trust. The pain worsens when local authorities seize your goods at customs or customers demand returns.

The best way to reduce counterfeit risk is to source directly from manufacturers with proven track records, internal QC teams, traceable shipments, and full compliance with international documentation standards.

Why working with certified factories reduces counterfeit risk in every step of procurement

When you choose a reliable manufacturer like us, you're minimizing counterfeit risk through several key checkpoints:

- Factory transparency: We offer clients complete visibility into our production operations. Every project has a dedicated project manager to supervise sampling, production, packaging, and final inspections.

- Internal QC teams: Unlike many trading companies or low-tier vendors, we don’t outsource our quality control. Our in-house team checks every batch, especially on details like labels, stitching, hardware, and packaging.

- Customizable packaging and labels: We help clients design unique packaging elements, including holographic tags and serial-coded labels that counterfeiters can’t easily reproduce.

- Full traceability: We document every production step with photos and videos, especially useful if customs officers request origin evidence.

- Genuine material sourcing: For accessories like belts, gloves, and scarves, we offer material sourcing with supplier invoices, dye lot reports, and physical testing results. This ensures not only safety but also authenticity.

Here’s a simple table showing how we tackle risks at different supply chain stages:

| Supply Chain Stage | Risk of Counterfeit | Our Countermeasure |

|---|---|---|

| Material sourcing | High | Verified suppliers, raw material invoices |

| Product design | Medium | Proprietary molds, barcode authentication |

| Production | Medium | On-site QC, project manager monitoring |

| Packaging | High | Custom tamper-proof designs, secure labels |

| Shipping & documentation | High | Full inspection photos, CO, Form A, HS code |

In the past 6 months, one of our American clients almost fell victim to a fraudulent vendor claiming to supply “branded headbands” at 30% lower than market price. He turned to us for verification, and we found the source using recycled materials and pirated brand tags. By re-routing the project through our team, he not only avoided counterfeit issues but also improved his profit margin with transparent sourcing and faster delivery.

How can companies prevent counterfeit products from entering their company or supply chain?

Sometimes, businesses trust the wrong link in the chain—middlemen, agents, or “low-cost” suppliers. That trust is quickly broken when substandard or fake goods arrive.

Companies can prevent counterfeit goods by implementing strict vendor validation, conducting pre-shipment inspections, and managing their suppliers through traceable and audited workflows.

What procurement procedures should importers follow to eliminate counterfeit risks from unknown vendors?

If you’re a buyer dealing with suppliers abroad, especially in China, here’s how we recommend vetting them to prevent counterfeits:

- Audit the manufacturer, not the agent. We’ve seen many cases where clients thought they were working with a factory—but it was just a middleman. We offer factory tours via video or in person for buyers who want full visibility.

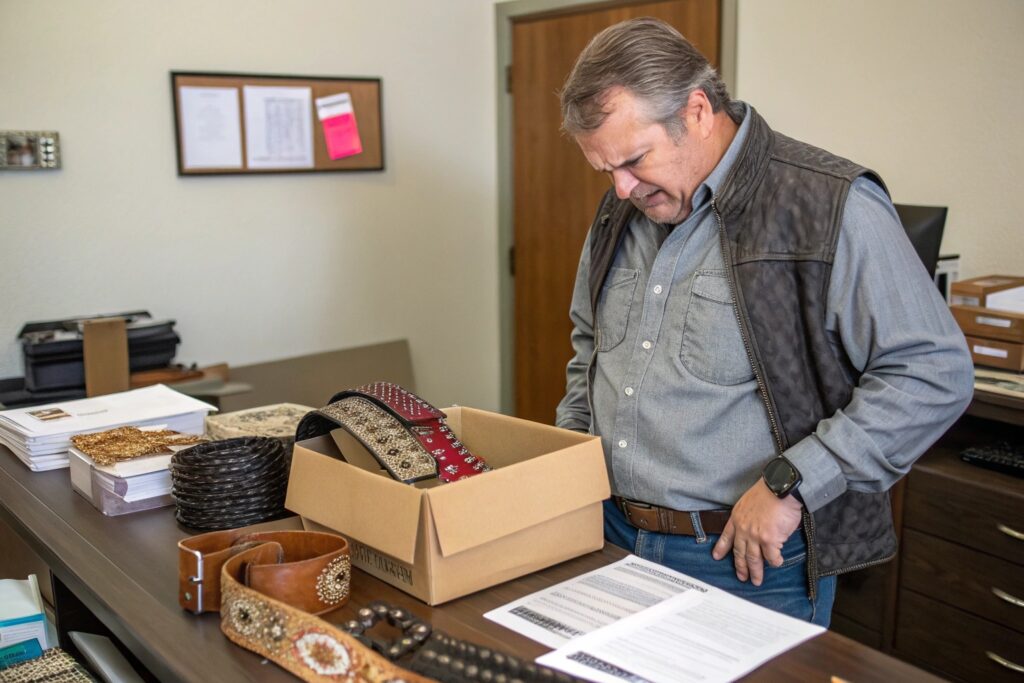

- Demand product authentication samples. For items like straw hats or leather belts, real material looks, smells, and wears differently than knockoffs. We provide testing reports and third-party lab certifications when needed.

- Use secure communication channels. We avoid platforms that hide vendor identity or offer no traceable contracts. Instead, we sign NDAs, supply contracts, and logistics service agreements that clients can verify.

- Centralize sourcing. If you’re sourcing multiple accessory types—scarves, gloves, caps—from different suppliers, you’re increasing counterfeit risk. We help clients consolidate orders across SKUs, with strict QC on every item.

A client from Europe told me his team spent weeks sorting through 3,000 fake scarves that were supposed to be cashmere. They were acrylic blends with incorrect labels and no certifications. He now relies on our consolidated manufacturing and inspection model, which has helped him restore buyer trust.

What is a technology used to prevent counterfeit products from entering the supply chain?

Traditional QC can't always stop determined counterfeiters. That’s why smart importers turn to technology to reinforce their supply chain protection.

One of the best technologies to prevent counterfeits is the use of RFID tags, blockchain-based tracking, and serialized barcodes that trace each product’s journey from production to delivery.

How can importers integrate technology into their accessory sourcing without high costs or complexity?

At AceAccessory, we help clients apply technology that fits their budget and industry:

1. QR Codes & Serialization

We can generate unique barcodes for each product batch. When scanned, the code shows:

- Product name

- Date of manufacture

- Factory ID

- Materials used

- Shipment date

This helps both retailers and customs verify the goods’ legitimacy.

2. RFID-Embedded Labels

For large-volume shipments to retailers like department stores or e-commerce hubs, we embed RFID chips inside clothing tags. These help track accessories across warehouses and prevent substitutions or tampering.

3. Blockchain Authentication

Some of our fashion clients prefer blockchain-based platforms to log each supply chain event. We can integrate with such platforms, which ensure the records are immutable and accessible by customs or customers.

4. Tamper-proof Packaging Design

We offer tamper-evident seals, security tapes, and holographic stickers that help prevent repackaging or resale of fake items.

Example Technology Comparison:

| Technology | Suitable For | Cost Impact | Traceability Strength |

|---|---|---|---|

| QR Codes | All accessories | Low | Medium |

| RFID Chips | Bulk orders, retailers | Medium | High |

| Blockchain Logs | Premium brands | High | Very High |

| Holographic Tags | Fashion, hats, belts | Low | Medium |

I always tell clients—investing in even simple solutions like QR codes can save thousands in lost sales and brand trust. In a recent case, we traced a shipment of rain hats from our facility to the buyer’s 3PL center. The QR code confirmed the batch authenticity when a distributor falsely claimed the goods were fake.

How can consumers prevent counterfeit products?

Buyers aren't the only ones at risk. Consumers are increasingly exposed to fakes sold online or through informal channels. Brands must help educate them too.

Consumers can prevent counterfeit purchases by buying from authorized retailers, checking packaging and product details, and using brand-provided authenticity checks like QR scans or serial numbers.

What steps can brands take to empower consumers in spotting fake accessories?

I’ve learned that empowering the end customer is just as crucial as securing the supply chain. Here’s what we recommend our clients do:

- Use branded authenticity cards. We can include cards with serial numbers and holographic logos inside packaging, especially for premium hair clips, shawls, and fashion belts.

- Offer authenticity scans. Our system allows brands to host a landing page where consumers can scan QR codes to verify their product’s details. This builds brand trust and reduces returns from “uncertain” customers.

- Make unboxing a verification process. From our clean packaging factories in Zhejiang, we prepare branded unboxing experiences with protective seals, tamper-evident bags, and clear brand guides.

- Launch education content. Our marketing team helps clients generate social media posts and guides teaching customers how to spot fakes. The more aware consumers are, the less likely they’ll fall for scams.

Here’s a helpful comparison for accessory buyers:

| Accessory Type | Common Counterfeit Clues | Authentic Element We Provide |

|---|---|---|

| Hair bands | Cheap elastic, unclear branding | Custom label, branded card |

| Belts | Cracked “leather,” generic buckles | Embossed brand, verified buckle stamp |

| Scarves | Uneven stitching, unwashed fabric smell | Material test card, fabric origin doc |

| Hats | Loose stitching, uneven size | Batch code inside brim, label seal |

A California-based client recently added a “Scan to Authenticate” feature to his store’s accessory listings. Within three months, not only did fake return requests drop by 70%, but his customer reviews highlighted the trustworthiness of the brand.

Conclusion

Reducing counterfeit risk in your accessory supply chain takes more than luck—it requires choosing trustworthy manufacturers, using technology, and educating customers. At AceAccessory, we help importers like you build that trust every day.