You're sourcing school bags—backpacks, totes, laptop sleeves—that need to survive the daily grind. They'll be stuffed with heavy textbooks, tossed on bus floors, scraped against lockers, and exposed to unpredictable weather. A bag that falls apart in a semester means disappointed customers, returns, and damage to your brand's reputation for quality. So, what materials truly stand up to the relentless demands of a student's life, balancing durability with weight, cost, and style?

The best materials for durable school bags are engineered synthetics and technical fabrics known for their high tensile strength, abrasion resistance, water repellency, and ease of cleaning. While traditional materials have their place, modern school bag durability is built on a foundation of nylon (especially Cordura®), polyester (often with PVC or PU coating), and reinforced canvas, frequently combined with robust components like YKK zippers and bar-tacked stress points. For manufacturers like us at Shanghai Fumao Clothing, selecting the right material isn't just about picking a fabric; it's about engineering a product system where the shell, lining, hardware, and construction work in unison to exceed the user's expectations for longevity.

Understanding this material science is key to creating a product that becomes a reliable companion for the entire school year and beyond. Let's dissect the top contenders and what makes them excel.

Why are Synthetic Fabrics Like Nylon and Polyester the Top Choice?

When it comes to the holy trinity of durability—strength, light weight, and water resistance—high-quality synthetic fabrics are unrivaled for school bag shells. They are not created equal, and their specifications matter immensely.

Nylon (particularly Nylon 6,6 or branded versions like Cordura®) is often the premium choice for high-stress areas. Its key advantages are:

- Exceptional Abrasion Resistance: Nylon fibers are incredibly tough and resistant to scuffing and tearing from rough surfaces. This is critical for the bottom of a backpack that sits on concrete or asphalt.

- High Tensile Strength: It can withstand heavy loads without stretching or ripping at the seams.

- Good Water Repellency: Naturally more water-resistant than cotton, and can be treated with durable water repellent (DWR) coatings for enhanced performance.

- Lightweight: Offers tremendous strength without adding significant weight to the bag itself.

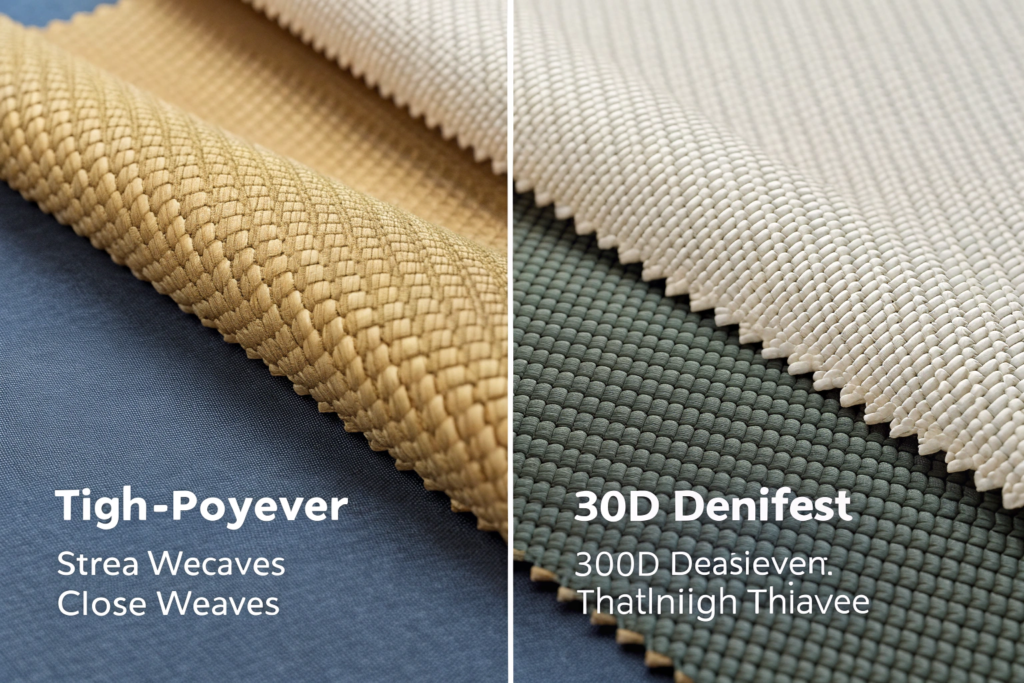

Polyester is the other workhorse. It is generally more affordable than nylon and has superior UV resistance, meaning it won't fade or degrade as quickly in sunlight. High-density polyester fabrics (e.g., 600D, 900D, 1200D) coated with PVC (Polyvinyl Chloride) or PU (Polyurethane) become highly water-resistant, easy to clean, and gain additional abrasion resistance. The "D" stands for Denier, indicating the thickness of the yarn; a higher denier usually means a heavier, tougher fabric. Industry standards from organizations like ASTM International define test methods for abrasion resistance that these fabrics must pass.

What is the Difference Between PVC and PU Coating?

Both coatings add water resistance and structure, but they have different profiles:

- PVC Coating: Creates a stiffer, more rugged feel. It's highly waterproof and offers excellent protection against abrasion and chemicals. However, it is less flexible, can be heavier, and has raised environmental concerns. It's often used for heavy-duty outdoor or industrial bags.

- PU Coating: Softer and more flexible than PVC, making it ideal for bags that need to be lightweight and packable. It provides very good water resistance and is more breathable. Modern PU coatings are also more environmentally friendly. For most school backpack applications, a high-density polyester with a PU coating offers the best balance of durability, weight, and performance.

Why is Fabric Denier (D) and Thread Count Important?

These are your objective metrics for toughness.

- Denier (D): The weight in grams of 9,000 meters of the thread. 300D-500D is common for general-use school bags. 600D-1000D+ is used for heavy-duty bags, reinforcement panels (like the bottom), and laptop compartments.

- Thread Count: The number of threads woven per square inch. A higher thread count in a tight weave (like a ripstop or ballistic weave) prevents tears from propagating. A loosely woven high-denier fabric can still be weak.

A bag might use 420D nylon for the main body for lightness, with 1000D Cordura nylon panels at the bottom and sides for abrasion resistance. This strategic use of materials optimizes cost and performance.

How Does Canvas Compare, and When is it a Good Option?

Canvas, particularly cotton canvas, evokes a classic, rugged aesthetic. Its durability comes from a tight, plain weave using thick yarns. However, its performance differs significantly from synthetics.

Advantages of Cotton Canvas:

- Natural Aesthetic and Feel: It has a timeless, non-technical look that appeals to certain markets.

- High Abrasion Resistance (When Dry): Thick canvas is very tough against scraping.

- Biodegradable: A natural fiber option.

Critical Disadvantages for School Use:

- Poor Performance When Wet: Cotton absorbs water, becoming very heavy and taking a long time to dry. It provides zero water protection for contents and can mildew.

- Lack of Inherent Water Resistance: Requires heavy waxing (like waxed canvas) to become water-repellent, which adds maintenance and changes the hand-feel.

- Less Consistent Strength: Strength can vary more than engineered synthetics.

Modern Solution: Synthetic Canvas. A superior alternative is polyester or nylon canvas. It mimics the look and weave of traditional canvas but inherits the water resistance, quick-drying properties, and colorfastness of synthetic fibers. For a durable school bag that needs a classic style, a high-denier synthetic canvas is often the best compromise. It aligns with the demand for durable and low-maintenance student gear.

Is Waxed Canvas a Viable Durable Material?

Waxed cotton canvas is durable and water-resistant, but it's a high-maintenance, niche material. The wax coating needs reapplication, it can transfer to clothes in heat, and it significantly increases the bag's weight and cost. For a mass-market school bag that requires zero maintenance and consistent performance, modern synthetics are overwhelmingly the more practical and reliable choice.

What About Ballistic Nylon and Cordura®?

These are specific, premium types of nylon:

- Ballistic Nylon: Originally developed for flak jackets, it's a thick, durable nylon with a distinctive 2x2 or 3x3 basket weave. It's extremely tough and abrasion-resistant, making it an excellent (though often more expensive) choice for high-end, lifelong school bags.

- Cordura®: A branded family of fabrics known for exceptional durability. Cordura® nylon is famous for its resistance to abrasions, tears, and scuffs. It's often used in high-wear areas. Cordura® fabric can also be made from recycled content, appealing to sustainability goals.

What Other Components are Crucial for Overall Durability?

The fabric shell is only part of the equation. A bag is only as strong as its weakest point. Attention must be paid to the reinforcements, hardware, and construction techniques.

Critical Components:

- Zippers: YKK zippers are the industry standard for reliability. For school bags, use #5 or #8 size reverse-coil zippers for main compartments—they are self-repairing and very strong. Water-resistant zippers (with a PU coating on the tape) are a premium feature that prevents water ingress through the zipper line.

- Stitching and Thread: Thread should be high-tenacity bonded nylon (e.g., TEX 70 or TEX 135). Critical stress points—like strap attachments, zipper ends, and handle bases—must be bar-tacked (a dense, rectangular reinforcement stitch) instead of just sewn with a straight line.

- Straps and Handles: Padding should be high-density, resilient foam. Strap material should be strong, wide, and securely attached with load-bearing webbing. SBS (Slide Buckle System) buckles should be used for adjustable sternum straps.

- Bottom Protection: The bag bottom should either be made from the highest denier fabric, have a rubberized or EVA foam panel glued and stitched on, or be constructed with a reinforced "base saver" design to protect against moisture and abrasion.

- Lining: The interior lining should be a durable, easy-to-clean fabric like polyester taffeta. Ripstop lining adds extra tear resistance.

Neglecting any of these components will create a failure point that renders the toughest shell material ineffective. Our manufacturing process at Shanghai Fumao Clothing emphasizes this holistic approach to durability.

Why is Bar-Tacking the Most Important Stitch?

A straight stitch can unravel if a single thread breaks. Bar-tacking involves sewing a tight, dense zigzag pattern back and forth over a small area. This distributes stress across hundreds of stitches, making it virtually impossible for the seam to pull apart. It is the single most effective sewing technique for preventing strap detachment and seam failure.

How Do You Choose the Right Hardware?

Hardware must be load-rated. Plastic buckles are acceptable for light-duty compression straps, but all load-bearing hardware (strap adjusters, attachment points) should be metal or engineered polymer (like ITW Nexus brand). Look for components that feel substantial, operate smoothly, and are from reputable suppliers. Cheap, thin plastic adjusters will snap under the weight of a full backpack.

What Role Do Design and Construction Play in Material Longevity?

Even the best materials can fail if the bag is poorly designed or constructed. Good design protects the materials from undue stress and wear.

Key design features that enhance durability:

- Padded Laptop Compartment: Prevents corners from digging into and wearing out the lining and inner fabric.

- Roll-Top or Flap Closures: Protect main zippers from direct exposure to rain and dirt.

- Reinforced Corners and Edges: Adding extra fabric layers or protective caps to areas most likely to scrape against surfaces.

- Internal Frame or Structured Back Panel: Prevents the bag from sagging and putting uneven stress on seams when loaded.

- Drainage Grommets: Small holes in the bottom allow water to escape if the bag is caught in rain, preventing mildew and water weight.

Construction quality is paramount. This includes:

- Consistent Stitch Per Inch (SPI): 8-12 SPI is standard for durable bags. Too few stitches weaken the seam; too many can perforate and weaken the fabric.

- Clean Seam Finishing: Using overlock or bias binding on raw fabric edges inside the bag prevents fraying, which can unravel entire seams over time.

- Quality Control During Assembly: Ensuring all components are aligned and attached correctly before proceeding to the next step.

This comprehensive approach to design-for-durability is a principle of long-life product engineering.

How Does a "Suspended Laptop Sleeve" Add Durability?

A suspended sleeve is not sewn to the bottom of the bag. When the bag is dropped, the laptop's impact is absorbed by the padding and the space below it, rather than transmitting the full force directly to the bag's bottom seam and fabric. This dramatically reduces the chance of a blowout tear at the bottom of the compartment.

What is the Impact of Ergonomic Design on Durability?

Ergonomic design, like a contoured back panel and padded, curved shoulder straps, encourages proper wear. A bag that is worn correctly distributes weight evenly. A bag that is uncomfortable is more likely to be carried by one strap or dragged, putting asymmetric and excessive stress on specific seams and attachment points, leading to premature failure. Comfort supports durability.

Conclusion

Selecting the best materials for a durable school bag requires a systems-thinking approach. It starts with high-performance shell fabrics like coated high-denier polyester or nylon, strategically reinforced with even tougher materials in high-wear zones. This material choice must be supported by industrial-grade components—YKK zippers, bar-tacked stitching, and load-rated hardware—all assembled with precision and reinforced by intelligent design features that protect the bag from its own payload and the environment.

For brands and retailers, investing in this material and construction quality is an investment in customer satisfaction, reduced return rates, and long-term brand equity. A truly durable school bag becomes a testament to your brand's commitment to quality, fostering loyalty that lasts long after the school year ends.

If you are looking to develop or source a line of school bags that are engineered for real-world durability, we invite you to partner with us. At Shanghai Fumao Clothing, we specialize in manufacturing accessories that are built to last, using optimal materials and proven construction techniques. For a consultation on your next school bag project, please contact our Business Director, Elaine. Let's build backpacks that can handle anything. Reach Elaine at: elaine@fumaoclothing.com.