You’re ready to source hats—beanies, sun hats, baseball caps, fedoras—for your brand or store. You've found factories that can make them, but the quotes and assurances seem similar on paper. Why should you specifically prioritize a factory with deep, proven export experience, especially to markets like North America or Europe? Isn't a hat just a hat? The reality is that the complexity and risk of international trade mean that a factory's production skill is only half the equation. The other, often more critical half, is its mastery of the entire journey from its production line to your warehouse.

Sourcing hats from a factory with extensive export experience is a fundamental risk-mitigation and efficiency strategy. It ensures your partner understands and can expertly navigate the intricate web of international compliance, logistics, documentation, quality standards, and business practices required by your home market. For a buyer, this translates to fewer hidden costs, reliable delivery, guaranteed product safety, and a seamless, professional partnership. At Shanghai Fumao Clothing, our decades of exporting accessories globally mean we don't just manufacture hats; we manage the complete process to ensure they arrive on your shelf correctly, legally, and on time.

This expertise is the invisible infrastructure that turns a production order into a successful commercial transaction. Let's examine why this experience is non-negotiable for a smooth and profitable sourcing operation.

How Does Export Experience Guarantee Regulatory Compliance and Avoid Costly Mistakes?

Every market has its own strict regulations for apparel and accessories. A factory without export experience may produce a beautiful hat that is illegal to sell in your country due to non-compliant materials, missing labels, or improper safety testing. An export-savvy factory builds compliance into its process from the start.

They understand and implement requirements such as:

- Labeling Laws: Correct care labels, fiber content tags (in the correct language), country of origin labels, and size labels that meet FTC (USA), Textile Labeling (Canada), or Textile Products (EU) regulations.

- Product Safety Standards: Adherence to standards like CPSIA (USA) for children's items, which limits lead and phthalates; REACH (EU) for chemical restrictions; and flammability standards for certain fabrics.

- Material Restrictions: Knowledge of banned or restricted substances (e.g., certain AZO dyes, nickel in metal components) and sourcing compliant materials accordingly.

- Testing and Certification: They know which third-party lab tests are required (e.g., for a sun hat's UPF rating) and can facilitate this testing, providing valid reports that protect you from liability and customs seizures.

An inexperienced factory might ignore these details, resulting in your shipment being held at customs, destroyed, or returned—a total financial loss. Resources like the U.S. Customs and Border Protection highlight how common compliance failures are among new importers.

What Are the Real Costs of Non-Compliance?

The costs go far beyond a delayed shipment:

- Customs Seizure and Fines: Non-compliant goods can be confiscated, with hefty fines levied on the importer (you).

- Forced Re-Export or Destruction: You may have to pay to ship the goods back or for their destruction.

- Lost Sales and Seasonality: Missing a key selling season due to compliance delays can devastate your revenue.

- Brand Liability and Lawsuits: Selling a non-compliant product (e.g., a children's hat with high lead levels) can lead to lawsuits, forced recalls, and irreversible brand damage.

An export-experienced factory acts as your first line of defense against these catastrophic risks.

How Does an Experienced Factory Handle Documentation?

Export documentation is a precise art. A single error on a Commercial Invoice, Packing List, or Certificate of Origin can delay clearance. Experienced factories have dedicated export departments that prepare flawless documents:

- Accurate HS Code Classification: They classify your hats with the correct Harmonized System code, ensuring proper duty rates and smooth clearance.

- BL/AWB Details: They ensure Bill of Lading or Air Waybill information matches your purchase order exactly.

- Special Certificates: They can prepare or procure any needed certificates (e.g., Non-Wood Packing Material certificate, Fumigation certificate for straw hats).

This precision eliminates a major point of failure in the supply chain.

How Does It Streamline Logistics and Communication?

International shipping is a complex dance involving freight forwarders, carriers, customs brokers, and ports. An inexperienced factory can become a bottleneck, causing delays and miscommunication at every step. An export-savvy partner operates like a well-oiled machine within this global system.

Logistical Efficiency: They have established relationships with reliable freight forwarders and understand the pros and cons of different Incoterms (e.g., FOB, EXW, CIF). They can advise you on the most cost-effective and reliable shipping method (air vs. sea, LCL vs. FCL) based on your order size and timeline. Their packing is optimized for international transit—using strong, standard cartons and proper palletization to prevent damage. They also understand critical timelines, like cut-off times for vessel bookings and the impact of holidays (e.g., Chinese New Year) on production and shipping schedules.

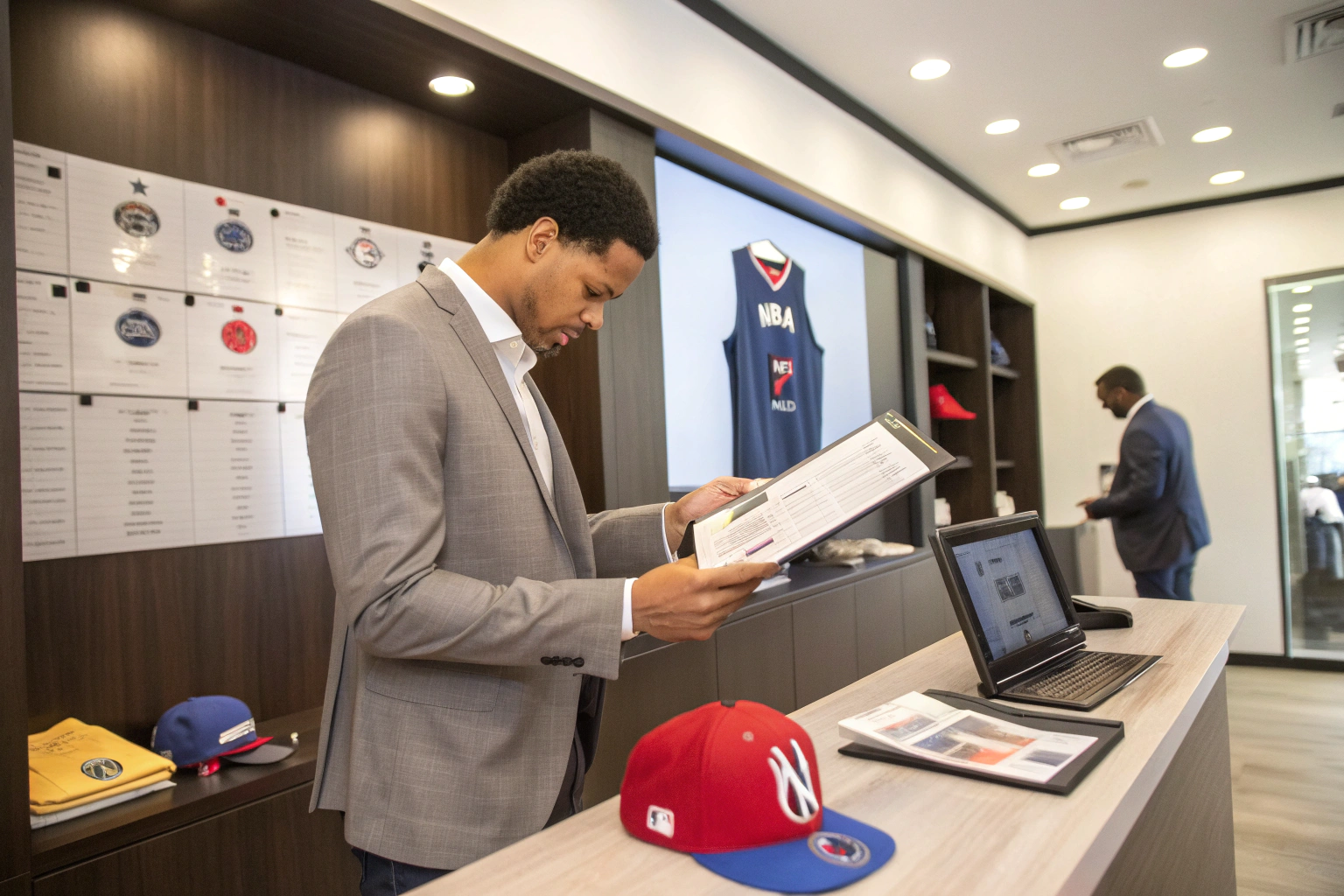

Professional Communication: Export-experienced factories employ proficient English-speaking project managers (PMs) who are your single point of contact. They understand Western business etiquette, respond promptly, and communicate clearly about progress, issues, and requirements. They are accustomed to working across time zones and can provide updates in your working hours. This eliminates the frustration, misunderstandings, and delays that plague communication with less experienced suppliers. At Shanghai Fumao Clothing, our PMs are trained to be proactive communicators, ensuring you are never in the dark, a practice that defines a true partnership in global trade.

How Does This Experience Prevent Shipping and Damage Issues?

Experience teaches hard lessons about packing. A factory that only ships domestically might use flimsy boxes. An export factory knows that hats must survive weeks at sea, multiple handlings, and variable humidity. They use:

- Weather-resistant cartons and plastic inner wrapping to prevent moisture damage.

- Proper stuffing and shaping inside each hat to maintain its form.

- Strategic palletization to prevent crushing.

- Clear, standardized labeling for easy identification at the destination warehouse.

This attention to detail drastically reduces the risk of receiving a container of damaged, unsellable goods.

Why is a Designated Project Manager a Game-Changer?

A dedicated PM who owns your order from sample to shipment is invaluable. They coordinate internally between production, QC, and the shipping department on your behalf. You have one person to ask for updates, provide approvals to, and resolve issues with. This streamlined communication prevents the "left hand not knowing what the right hand is doing" scenario common with factories where sales, production, and shipping are disconnected.

How Does Export Experience Translate to Superior Quality Consistency?

Factories that regularly serve demanding international buyers have internalized the quality expectations of those markets. They don't just aim for "good enough"; they have systematic processes to deliver consistent, high-standard quality that meets the scrutiny of Western retailers and consumers.

Systematic Quality Control (QC): Export-oriented factories operate with formal QC systems, often aligned with ISO 9001 principles. Their process includes:

- Incoming Material Inspection: Checking fabric, brim stiffeners, and trims against standards before production begins.

- In-Process QC (IPQC): Inspectors on the production line monitor stitching, shaping, and assembly in real-time.

- Final Random Inspection (FRI): They conduct pre-shipment inspections based on AQL (Acceptable Quality Level) sampling plans. They can provide detailed inspection reports with photos and data, giving you objective proof of quality before shipment.

- Understanding of "Marketable" Quality: They know that a loose thread, slightly off-center embroidery, or a minor color deviation that might be acceptable in some markets is a reject in North America or Europe.

This proactive approach to quality prevents the nightmare of discovering widespread defects only after the goods have arrived at your warehouse.

What is AQL and Why Does it Matter?

AQL (Acceptable Quality Level) is an international sampling standard used to determine if a batch of products meets quality requirements. An export-experienced factory uses AQL to objectively decide whether to ship. For example, a common standard for general apparel is AQL 2.5 for major defects and AQL 4.0 for minor defects. This means they statistically sample the batch and will fail it if the number of defective pieces found exceeds the limit. Using AQL removes subjectivity and ensures a consistent, agreed-upon quality level for every order.

How Does This Experience Benefit Product Development?

Their exposure to global trends and materials means they can be a valuable partner in development. They can advise on which materials hold up best to washing (for beanies), which constructions provide the best sun protection (for wide-brim hats), or what new sustainable fabrics are available. This collaborative input, based on real-world feedback from other export markets, can significantly improve your final product.

What Are the Financial and Risk Management Advantages?

Export experience brings a level of professionalism that directly protects your financial investment and minimizes business risk. They operate with transparency and understand the standards that govern international commercial transactions.

Financial Transparency and Security:

- Clear, Detailed Quotations: Their quotes are comprehensive, breaking down costs for materials, labor, trims, and packaging separately. There are fewer hidden fees.

- Standard and Secure Payment Terms: They operate with standard terms like 30% deposit with order, 70% balance before shipment, often facilitated through secure platforms or letters of credit. They understand and respect these financial protocols.

- Insurance Knowledge: They can advise on marine cargo insurance and understand liability under different Incoterms.

Risk Mitigation:

- Production Planning Reliability: They accurately forecast lead times because they understand their own capacity and supply chain dependencies.

- Problem Anticipation and Solution: Having faced myriad issues—from port strikes to material shortages—they proactively communicate problems and present solutions, rather than hiding them until it's too late.

- Intellectual Property (IP) Respect: Factories that work with major international brands understand the importance of IP protection and are more likely to have strict protocols to safeguard your designs, as their reputation depends on it.

This professional approach turns your factory from a potential source of risk into a reliable business partner that shares the goal of a successful, on-time delivery.

How Do Secure Payment Practices Protect You?

Export-experienced factories are accustomed to the 30/70 payment split because it's a balanced risk. The deposit covers their material costs, and the final payment upon your approval of shipping documents ensures you have leverage until the goods are irrevocably on their way to you. They are less likely to demand risky terms like 100% payment upfront.

Why is Accurate Lead Time Forecasting Critical?

For retail, timing is everything. An experienced factory provides a realistic lead time that includes buffer for sourcing, production, QC, and booking shipping. They won't promise an impossible deadline just to get your order, because they know a late shipment damages their reputation as much as it hurts your business. This reliability allows you to plan your marketing and sales activities with confidence.

Conclusion

Choosing a hat factory with extensive export experience is one of the most significant de-risking decisions you can make as an importer. It means partnering with an organization that masters not only the craft of making hats but also the complex, rules-based world of global trade. This expertise ensures compliance, enables seamless logistics, guarantees consistent quality, and provides financial security.

While a less experienced factory might offer a slightly lower initial unit cost, the hidden risks and potential costs of errors in compliance, communication, and logistics can easily erase those savings and threaten your entire business. The true cost-saving is in the smooth, predictable, and professional execution of your order from start to finish.

If you are looking for a hat manufacturing partner with proven export expertise to North America, Europe, and beyond, we invite you to connect with us. At Shanghai Fumao Clothing, we combine production excellence with decades of export mastery. For a consultation on your next hat order, please contact our Business Director, Elaine. Let's ensure your hats are not only well-made but also seamlessly delivered. Reach Elaine at: elaine@fumaoclothing.com.