You've launched a new line of scarves, and they're selling fast. But then, a customer emails asking, "What are these made of? And who made them?" You realize you don't have the full story from your factory. This scenario is becoming common. Today's consumers and business buyers don't just want a great product; they want a great story they can trust. They are demanding to know the origins of what they buy, putting immense pressure on brands and their suppliers.

Transparency is the future of fashion manufacturing because it has evolved from a niche ethical preference into a core business imperative for risk management, brand equity, and market competitiveness. It means openly sharing information about a product’s journey—from sustainable sourcing of raw materials and ethical factory conditions to carbon footprint data and end-of-life options. This shift is driven by consumer demand, investor pressure, and new regulations. For brands, partnering with a transparent manufacturer is no longer just about avoiding bad publicity; it's about building a resilient, future-proof supply chain that aligns with modern values and complies with evolving laws like the Uyghur Forced Labor Prevention Act (UFLPA) in the US and the EU's Corporate Sustainability Due Diligence Directive (CSDDD).

In short, opacity is a liability. A lack of supply chain visibility can lead to devastating compliance failures, reputational damage, and lost sales. Conversely, transparency builds trust, fosters innovation in sustainable practices, and creates a tangible point of difference in a crowded market. This article will explore the key drivers behind this irreversible trend and explain how forward-thinking manufacturers are adapting, providing a clear blueprint for why and how you should prioritize transparency in your next partnership.

How Does Supply Chain Visibility Reduce Business Risk?

Imagine discovering that a key component in your bestselling hair clips is linked to a controversial environmental practice or an unauthorized subcontractor with poor working conditions. The news breaks, and your brand is on the defensive overnight. This isn't a hypothetical fear; it's a modern business risk that transparency directly mitigates.

Supply chain visibility reduces business risk by acting as an early warning system. When you have clear insight into every tier of your production network, you can proactively identify and address issues before they become crises. This includes monitoring for ethical sourcing violations, ensuring regulatory compliance with laws like the UFLPA, assessing factory safety standards, and verifying material traceability. For example, knowing the exact mill that produced your cotton for scarves allows you to verify certifications like BCI (Better Cotton Initiative) or Organic Content Standard (OCS), shielding you from claims of using cotton from problematic regions. In an era of stringent customs compliance, detailed documentation of origin is crucial to prevent costly shipment detentions or seizures at the border.

Beyond compliance, visibility is critical for operational resilience. The pandemic and geopolitical tensions exposed the fragility of opaque, complex supply chains. If your manufacturer is transparent about its own network of sub-suppliers and raw material inventory, you can better anticipate and navigate disruptions like material shortages or port delays. This enables smarter inventory planning and more reliable delivery promises to your customers. Essentially, transparency transforms your supply chain from a mysterious cost center into a manageable, strategic asset. This level of operational clarity complements the foundational need for clear communication with your manufacturer, where trust and information flow are paramount.

What are the compliance risks of an opaque supply chain?

An opaque supply chain poses severe compliance risks, primarily from violating increasing global due diligence legislation. The Uyghur Forced Labor Prevention Act (UFLPA) in the US creates a "rebuttable presumption" that goods made wholly or in part in China's Xinjiang region are made with forced labor and are prohibited from import. Without verifiable, documented traceability proving your accessories (e.g., cotton hats, wool gloves) contain no inputs from that region, your entire shipment can be detained by U.S. Customs and Border Protection (CBP), leading to massive financial loss. Similarly, the upcoming EU CSDDD will require large companies to identify, prevent, and address human rights and environmental impacts in their value chains. If your manufacturer cannot provide the necessary audit trails and proof of social compliance (like SMETA audits), you risk non-compliance, hefty fines, and exclusion from major markets.

How does traceability prevent product recalls and delays?

Product traceability systems prevent recalls and delays by enabling pinpoint accuracy. If a quality issue arises—say, a specific batch of metal alloy in hair clips is found to have a nickel content above legal limits—a traceable system allows you to identify exactly which production lots are affected, rather than recalling your entire inventory. This limits the scope, cost, and brand damage of the recall. For delays, traceability works hand-in-hand with production monitoring. Knowing the real-time status of each component (e.g., "zippers for bags delayed at sub-supplier") allows your manufacturer and you to quickly find alternatives or adjust schedules, rather than discovering the problem only when final assembly is supposed to start. Platforms like Traceability software are becoming essential tools for proactive manufacturers to offer this level of insight, turning potential disasters into manageable incidents.

Why are Consumers and Brands Driving the Demand for Transparency?

The push for transparency isn't coming from regulators alone. A powerful force is the market itself. End consumers, particularly Millennials and Gen Z, are voting with their wallets, favoring brands that align with their values. Simultaneously, brands themselves are seeking transparent partners to protect and enhance their own reputations.

Consumers are driving demand because access to information has empowered them. They use apps to scan sustainability labels, follow influencers who dissect brand ethics, and expect brands to be accountable. They want to know if the straw hat they buy is made with respect for artisan communities, or if the dyeing process for a scarf polluted local waterways. This isn't a fringe trend; it's mainstream consumer behavior. A brand's commitment to transparency, validated by partnerships with credible manufacturers, directly influences purchase decisions and builds fierce customer loyalty. For the brand, this consumer pressure translates into a concrete need: they must be able to tell an authentic, verifiable story about their products.

For brands and retailers, especially large ones, the demand is also about risk management and investor relations. Publicly traded companies face scrutiny from ESG (Environmental, Social, and Governance) investors who assess supply chain ethics. A scandal involving a supplier can lead to stock devaluation. Therefore, brands are conducting stricter supplier audits and demanding proof of ethical manufacturing practices. They need manufacturers who don't just claim to be ethical but can demonstrate it with data—from energy consumption in the factory to fair wage documentation. This creates a trickle-down effect where only manufacturers with transparent, verifiable operations can qualify to supply major global brands, making transparency a key differentiator for factories like ours at Shanghai Fumao Clothing.

How do sustainability certifications build brand trust?

Sustainability certifications provide a third-party, verifiable shorthand for trust. When a brand can state that its products are made in a SA8000 certified facility (ensuring decent working conditions) or use GRS (Global Recycled Standard) certified recycled polyester, it moves from making a vague claim to presenting a credentialed fact. Certifications like OEKO-TEX® STANDARD 100 for tested, harmless textiles give consumers peace of mind about product safety. For a brand, partnering with a manufacturer that holds these certifications reduces the burden of proof. It allows the brand to confidently market its products' ethical and sustainable attributes, knowing they are backed by rigorous, audited standards. This tangible proof is far more powerful than marketing slogans and is a critical tool in building a reputable, trustworthy brand image in a skeptical market.

What is the role of technology in enabling transparency?

Technology is the ultimate enabler of scalable, credible transparency. It moves the process from paper-based, easily falsified audits to real-time, data-driven visibility. Blockchain technology, for instance, can create an immutable record of a product's journey, from raw material bale to finished beanie, allowing anyone to scan a QR code and see its provenance. Internet of Things (IoT) sensors in factories can monitor energy and water usage, providing data for carbon footprint calculations. Platforms like Retraced or Sourcemap allow brands and their manufacturing partners to collaboratively map and share supply chain data with stakeholders. For manufacturers, investing in these technologies is no longer futuristic; it's a competitive necessity to meet the demands of leading brands and provide the level of detail required for robust quality control and compliance in the modern era.

How Can Transparent Factories Offer Competitive Advantage?

In a competitive bidding scenario, where several factories quote similar prices, what makes one stand out? Increasingly, it's their ability to demonstrate transparency. This is not just a "nice-to-have" for marketing; it directly translates into tangible business advantages for both the factory and its clients.

Transparent factories gain a competitive edge by offering risk mitigation as a service. They attract and retain premium brands that cannot afford supply chain scandals. Their openness becomes a foundational element of trust, which leads to longer-term, more collaborative partnerships. This stability allows for better planning, investment in innovation, and often, more efficient operations. Furthermore, a transparent approach to production processes and costing can lead to more innovative problem-solving with clients. For example, by openly analyzing the bill of materials (BOM) for a belt, a transparent factory can work with the client to identify where switching to a different, more sustainably sourced leather or buckle can reduce cost or environmental impact without sacrificing quality.

This advantage extends to market access. As mentioned, large retailers and brands have stringent vendor compliance programs. A factory with a proven track record of transparency, backed by audit reports and digital traceability, passes these vetting processes more easily. This opens doors to larger, more stable orders. For the client (the brand), the competitive advantage lies in their own market. They can use their partnership with a transparent manufacturer as a key point of differentiation in their storytelling, appealing to conscious consumers and meeting corporate sustainability goals. This aligns perfectly with the need for agility in fast development cycles, as a trusted, transparent partnership streamlines the entire process from design to delivery.

Does transparency lead to better pricing and efficiency?

Paradoxically, yes. While implementing transparency systems (like audits, traceability software) has an upfront cost, it often leads to greater efficiency and more accurate, fair pricing in the long run. Transparency forces a meticulous examination of every process, from material waste on the cutting room floor to energy inefficiencies. Identifying and reducing this waste lowers the factory's operating costs, savings that can be shared with the client. In terms of pricing, a transparent factory provides a detailed cost breakdown, not just a final unit price. This shows the client exactly what they are paying for: material cost, labor, overhead, and profit margin. This builds trust and avoids the suspicion of hidden fees. It also allows for more productive negotiations focused on value engineering—"If we adjust this design detail, we can save 10% on material without affecting the look."

How does openness foster innovation in product development?

A transparent culture breaks down silos and fosters collaboration, which is the bedrock of innovation. When a factory is open about its capabilities, limitations, and insights into new sustainable materials (like recycled PET felt for hats or biodegradable hair bands), it invites the client to co-create. This partnership can lead to developing exclusive, patentable products or processes. For instance, a client's design team, working openly with the factory's technicians, might develop a new, faster method for attaching embellishments to hair clips, reducing production time. This level of collaborative R&D is only possible in a relationship built on mutual trust and open information sharing, turning the manufacturer from a mere executor into a strategic innovation partner.

What Practical Steps is a Modern Factory Taking?

Understanding the "why" of transparency is one thing; seeing the "how" is what gives brands confidence. Modern, forward-thinking factories are taking concrete, measurable steps to embed transparency into their operations, moving from rhetoric to reality.

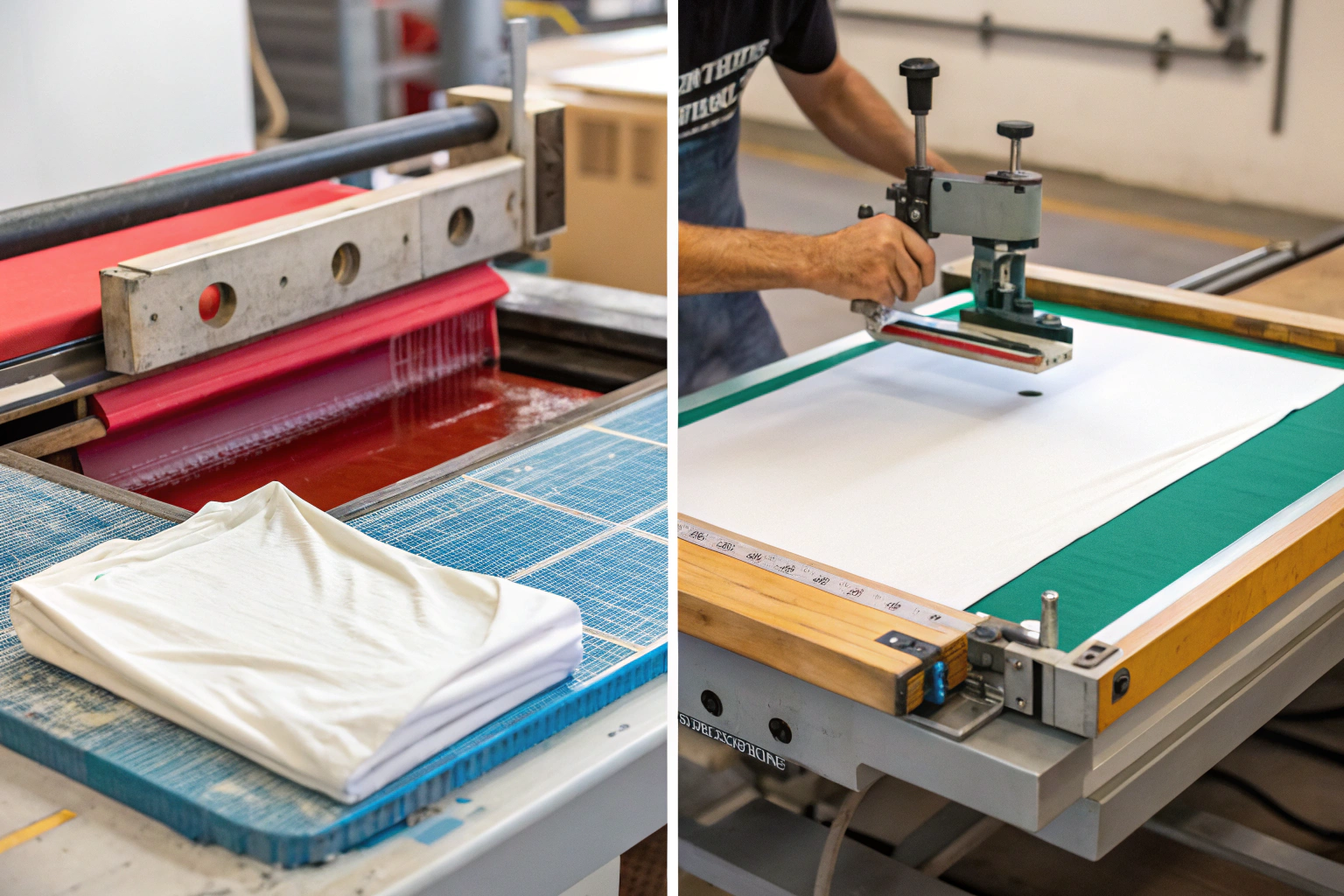

The journey begins with internal governance and policy. A modern factory will have a publicly available Code of Conduct that outlines its commitments to ethics, sustainability, and transparency. This is backed by investing in management systems like ISO 9001 for quality and ISO 14001 for environmental management, which require documented procedures and continuous improvement. Practically, this means implementing digital tools for supply chain mapping to identify all sub-suppliers, and requiring them to adhere to the same standards. For production, this involves using ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) software to track orders, materials, and production stages in real time, data which can be selectively shared with clients upon request.

On the factory floor, steps include obtaining relevant product certifications (e.g., OEKO-TEX®, GOTS for organic cotton) and undergoing regular third-party social audits like SMETA or BSCI to verify working conditions. Environmental steps might include installing water treatment systems for dyeing processes, switching to renewable energy, and conducting life cycle assessments for key products. Crucially, a modern factory doesn't just do these things; it communicates them. It provides clients with transparency reports, access to audit summaries, and even digital passports for products. These practical steps demonstrate a commitment that goes beyond words, ensuring that every aspect of the partnership, including the final logistics and fulfillment, is handled with integrity and openness.

What does a factory social compliance audit involve?

A social compliance audit is a rigorous examination of a factory's operations against international labor standards. Key elements include:

- Working Hours & Wages: Reviewing time cards and payroll records to verify compliance with local laws on working hours, overtime pay, and minimum wage.

- Health & Safety: Inspecting facilities for fire safety (exits, extinguishers), machinery guards, chemical handling, and general workplace conditions.

- Child & Forced Labor: Checking employment records and interviewing workers to confirm no underage or involuntary labor is used.

- Freedom of Association: Ensuring workers have the right to form or join worker organizations.

- Management Systems: Evaluating policies, training records, and grievance mechanisms for workers.

Audits like SMETA (Sedex Members Ethical Trade Audit) are common. A factory that regularly passes such audits, and is willing to share corrective action plans for any findings, provides tangible proof of its ethical commitment.

How are digital product passports changing the game?

Digital Product Passports (DPPs) are set to revolutionize transparency. Driven by EU regulations like the Ecodesign for Sustainable Products Regulation (ESPR), DPPs will be mandatory for many product categories. A DPP is a unique digital identity for a physical product, accessible via QR code or RFID tag. For a scarf, its DPP could contain information on the source of the wool, the dyes used, the carbon footprint of its production, care instructions, and recycling information. For a factory like Shanghai Fumao Clothing, this means systematically collecting and structuring this data for every product. It transforms transparency from a static report into an interactive, consumer-facing tool. It empowers the end-buyer, holds the entire chain accountable, and fundamentally changes how products are valued—based on their environmental and social impact as much as their aesthetic and price.

Conclusion

Transparency in fashion manufacturing is not a passing trend but the foundational cornerstone of the industry's future. It is the critical response to interconnected challenges: consumer demand for ethics, stringent regulatory landscapes, investor focus on ESG, and the operational need for resilient supply chains. The risks of opacity—compliance failures, reputational ruin, and lost consumer trust—are simply too great to ignore. The future belongs to manufacturers and brands that can prove their products are made responsibly, with integrity at every step.

This shift requires a new kind of partnership. It moves beyond transactional relationships to collaborative alliances built on data, openness, and shared values. From traceability systems that map a product's origin to digital passports that tell its story, the tools for transparency are here. Factories that embrace them are not just becoming more ethical; they are becoming more efficient, innovative, and competitive.

If you are looking to future-proof your brand and build a supply chain you can be proud to talk about, partnering with a transparent manufacturer is the essential first step. At Shanghai Fumao Clothing, we are committed to this journey, integrating transparent practices, ethical audits, and clear communication into every project. We believe that great products come from great processes. To explore how a transparent partnership can benefit your next line of accessories, we invite you to contact our Business Director, Elaine, for a confidential discussion at: elaine@fumaoclothing.com.