You envision a collection of sumptuously soft scarves, luxurious beanies, or lightweight yet warm sweaters that define the pinnacle of your brand's quality. The material at the heart of this vision is luxury cashmere blend—not just any wool, but a premium fusion that marries the legendary softness and warmth of cashmere with the performance, durability, or unique character of another noble fiber. Finding a supplier who can deliver authentic, high-grade materials and translate them into impeccable finished goods is a critical, complex task. How do you navigate this specialized supply chain to find a partner worthy of your luxury vision?

To find a reliable supplier for luxury cashmere blends, you must target specialized spinners and vertically integrated manufacturers with verifiable expertise in high-end natural fibers, not general fabric mills. The search requires a focus on certifications of origin and quality, transparent supply chain auditing, and a manufacturer's proven ability in handling delicate, premium yarns through cutting and sewing. A true luxury supplier will be a partner in fiber selection, advising on optimal blend ratios (e.g., cashmere-silk, cashmere-camel hair, cashmere-merino wool) for your specific product's drape, strength, and price point.

This pursuit is as much about integrity and storytelling as it is about technical specification. In the luxury market, provenance is paramount. Your supplier must provide a clear, ethical narrative from herd to hanger. The following guide details the strategic steps, key questions, and red flags to consider when sourcing the foundation for your most premium accessories.

Where Do You Start the Search for Authentic Luxury Fiber Suppliers?

The journey for luxury cashmere does not begin on general B2B platforms like Alibaba. It starts in the specialized ecosystems of high-end textiles, where reputation, relationships, and proven quality are the currency.

Your primary targets should be:

- Specialized Yarn Spinners in Known Regions: The world's finest cashmere originates from specific regions (Inner Mongolia, Mongolia, Afghanistan, Iran), and the best blending and spinning expertise is concentrated in Italy (Biella), Scotland, and Japan. Seek out spinning mills in these regions that specialize in luxury natural fibers. They often supply yarn to fashion houses and may also offer Made in Italy or Made in UK manufacturing partnerships.

- Vertically Integrated Manufacturers: These are factories that control the process from yarn sourcing (or even raw fiber purchasing) through to finished garment production. They offer the greatest consistency and quality control. Look for manufacturers in China (specifically Ningxia, Hebei, or partners of Italian mills), Italy, and Scotland that advertise cashmere and luxury blend expertise.

- High-End Textile Trade Shows: Events like Première Vision (Paris), Pitti Filati (Florence), and SpinExpo are where luxury spinners and mills showcase their latest developments. Attending allows you to feel yarns, review certifications, and build direct relationships.

- Professional Networks & Sourcing Agents: Leverage LinkedIn to search for "Cashmere Spinner," "Luxury Knitwear Manufacturer," or "Fine Yarn Development." Hiring a reputable sourcing agent with deep connections in the cashmere industry can provide access to vetted, top-tier suppliers that are not publicly marketing.

When making first contact, your communication must reflect a serious understanding of luxury. Instead of asking for a generic price list, prepare a technical and philosophical brief. Mention specific blend interests (e.g., "70% cashmere, 30% mulberry silk for a lightweight summer scarf"), ask about fiber diameter (micron count) and yarn ply, and inquire directly about certifications and traceability. A legitimate supplier will welcome these detailed questions and respond with specifications, not just a price. A manufacturer like Shanghai Fumao Clothing, which has established channels for premium materials, can be a gateway to this specialized network, offering both sourcing assurance and production excellence.

Why is geographic origin so critical for cashmere?

Geographic origin is a primary indicator of quality. Cashmere from Inner Mongolia and Mongolia is renowned for its long, fine fibers, resulting in stronger, smoother, and less pil-prone yarn. The harsh climate produces a superior undercoat. Furthermore, origin ties directly to ethical sourcing. Regions with established herding practices and regulations (like the Sustainable Fibre Alliance standards in Mongolia) are more likely to ensure animal welfare and sustainable land management. A supplier should be able to trace their raw cashmere back to specific regions and herds, not just a country of processing.

What are the red flags when sourcing luxury blends?

Be highly cautious of suppliers who:

- Cannot provide verifiable certification (e.g., Cashmere of Mongolia mark, GCS - Good Cashmere Standard, Oeko-Tex® Standard 100).

- Quote prices significantly below market average (likely indicating adulteration with wool, yak hair, or recycled fibers).

- Are vague about blend percentages or micron counts.

- Only sell finished goods but cannot provide yarn or fabric swatches for your own testing.

- Have no visible partnerships or client list of other reputable brands.

Luxury cashmere is a premium product with a corresponding cost; if a deal seems too good to be true, it almost always is.

What Certifications and Quality Metrics Are Non-Negotiable?

In the luxury sector, trust is built on verifiable data. Certifications and technical specifications are your objective guarantees of quality, ethics, and authenticity. They replace marketing claims with measurable standards.

Key Certifications to Demand:

- Fiber Origin & Quality Certificates: The "Cashmere of Mongolia" certification guarantees the cashmere is sourced from Mongolian goats and meets strict quality criteria. The Good Cashmere Standard (GCS) is a broader certification ensuring sustainable and ethical practices from farm to final product.

- Oeko-Tex® Standard 100: This is crucial. It certifies that the yarn or fabric has been tested for a wide range of harmful substances and is safe for human skin—a must for luxury items worn directly against the body.

- Responsible Wool Standard (RWS) / Responsible Mohair Standard (RMS): If your blend includes wool or mohair, these certifications ensure animal welfare and land management.

- Traceability Documentation: Ask for a Transaction Certificate (TC) or a Lifecycle Assessment document that can trace the fiber batch back through processing to the raw material source.

Technical Quality Metrics:

- Micron Count (Fiber Diameter): This is the single most important quality indicator. Luxury cashmere is typically below 16.5 microns (human hair is about 75 microns). Ultra-fine cashmere can be 14.5 microns or less. The lower the number, the softer and more precious the fiber. Your supplier should provide test reports (from labs like SGS or Intertek) showing the average micron and standard deviation (lower is better, indicating consistency).

- Staple Length: Longer fibers (over 36mm) spin into stronger, smoother yarns that pill less. Shorter fibers are cheaper and produce weaker, fuzzier yarn.

- Blend Ratio Verification: The contract should guarantee the exact percentage of each fiber (e.g., 80% cashmere, 20% silk). Reputable spinners will allow for third-party composition testing.

The Role of Testing: Before finalizing an order, you should independently test the provided yarn or fabric swatch. Send a sample to an international lab for a fiber composition analysis and micron measurement. This due diligence protects your brand from costly fraud and ensures the material matches the specification you will market to your customers. A transparent supplier will encourage this and may even provide recent test reports upfront.

How do you verify micron count and blend ratios?

Verification requires third-party laboratory testing. The standard test for fiber diameter is Microscopy or Laserscan. For blend ratios, Chemical Fibre Analysis (using solvents to dissolve specific fibers) or Microscopic Examination is used. Reputable testing laboratories include SGS, Bureau Veritas, Intertek, and ITS. You should budget for this testing as a standard part of your sourcing cost for luxury materials. The supplier's own test report is a good starting point, but an independent verification is the gold standard for brand assurance.

What is the difference between virgin cashmere and recycled cashmere in blends?

This is a critical distinction for quality and marketing:

- Virgin Cashmere: Comes directly from the first processing of raw goat hair. The fibers are long, strong, and intact, resulting in a soft, durable, and low-pill yarn. This is the standard for true luxury.

- Recycled/Regenerated Cashmere: Made from post-industrial or post-consumer cashmere fabric scraps that are shredded back into fiber. The process shortens the fibers significantly, resulting in a yarn that is weaker, more prone to pilling, and has a fuzzier hand-feel. While more sustainable, it is not equivalent in quality to virgin cashmere. A blend labeled as cashmere must specify if it is recycled; if unspecified, it is assumed to be virgin. For a luxury product, insist on virgin cashmere as the core of your blend.

How Does the Manufacturing Process Impact the Final Product?

Securing the perfect yarn is only half the battle. The manufacturing partner who transforms that yarn into your accessory must have the technical expertise, delicate handling, and quality control protocols worthy of the material. The wrong production process can ruin even the finest cashmere.

Key Manufacturing Capabilities to Assess:

- Knit vs. Woven Expertise: Determine your product needs. Fine-gauge knitting (using 12-gauge or finer machines) is ideal for lightweight, drapey scarves and sweaters. Woven cashmere (like twill or challis) offers more structure for blazers or structured bags. Your factory must specialize in your chosen technique.

- Dyeing Proficiency: Luxury cashmere is often dyed in the yarn (skein dyeing) rather than as finished fabric. This allows for richer, more penetrating color and is less stressful on the fibers. Ask about their dye house: do they use low-impact, Oeko-Tex certified dyes? Can they achieve consistent, level color across large batches?

- Finishing Techniques: The "hand of the fabric"—its softness and drape—is heavily influenced by finishing. Processes like washing, softening, and pressing must be meticulously controlled. Brushing or raising can add a soft nap but must be done carefully to avoid weakening the fabric. A luxury factory will have a dedicated finishing department.

- Quality Control at Every Stage: From checking yarn tension during knitting to inspecting for holes, dye spots, and sewing imperfections, the QC must be relentless. Ask about their in-process inspection rates and final inspection AQL standards.

The Sampling Phase is Critical: The sampling process with a luxury manufacturer will be extensive and costly, but it is non-negotiable. Expect multiple rounds:

- Yarn/Blend Approval: Testing swatches in different blend ratios.

- Lab Dip Approval: Approving the exact color on the actual yarn.

- Knitted/Woven Blank Approval: Approving the fabric's weight (GSM), gauge, and hand-feel.

- Fitting/Prototype Sample: Checking the pattern and construction.

- Pre-Production Sample: Made with all correct materials and trims.

Each stage is an opportunity to catch issues before bulk production. A factory experienced in luxury goods will guide you through this patiently and transparently.

Why is "Made in Italy" or "Made in Scotland" associated with quality?

The association stems from centuries of accumulated expertise, strict regional regulations, and investment in advanced technology. Regions like Biella, Italy, and the Scottish Borders have clusters of specialists in every step of the luxury wool and cashmere process—sorting, spinning, dyeing, weaving/knitting, and finishing. This deep, localized knowledge, combined with a cultural commitment to craftsmanship, results in superior product integrity and consistency. While not the only source of quality, these designations carry significant weight in the luxury market and often justify a higher price point.

How do you assess a factory's true capability with delicate fibers?

Request a factory audit or detailed video tour. Look for:

- Clean, humidity-controlled environments to prevent static and fiber damage.

- Modern, computerized knitting/weaving machines that offer precise tension control.

- Hand-finishing stations for delicate tasks like linking sweater seams or meticulous hand-stitching.

- On-site or partnered dye house with quality control labs.

- Portfolio of past work with recognizable luxury or high-end brands (they may be discreet, but should show anonymized examples).

Ask for references and speak to their other clients about consistency, communication, and problem-solving.

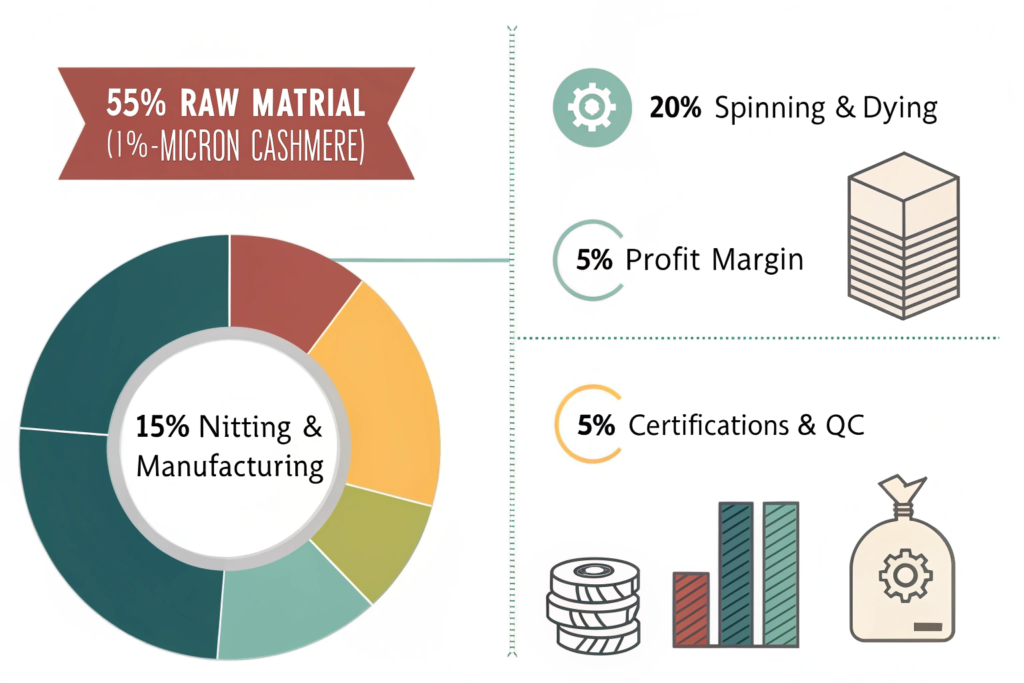

What Are the Cost Drivers and How to Navigate Pricing?

Luxury cashmere blend products command premium prices for a reason. Understanding the key cost drivers helps you evaluate quotes intelligently and avoid being undervalued or overcharged.

Primary Cost Drivers:

- Raw Material Cost: This is the largest component. Price is determined by:

- Cashmere Micron & Staple Length: Finer, longer fibers can cost 2-3 times more than shorter, coarser cashmere.

- Blend Partner: Silk, camel hair, and baby alpaca are expensive. Merino wool is a more cost-effective but still high-quality partner.

- Market Volatility: Cashmere prices fluctuate based on climate, demand, and global supply.

- Spinning Cost: Creating a fine, even, blended yarn requires advanced machinery and skill. More complex blends (e.g., three fibers) cost more to spin.

- Manufacturing Complexity: A simple scarf is less expensive to produce than a fully-fashioned, linked sweater with intricate cable patterns. Higher gauge (finer knit) also increases production time and cost.

- Labor & Overhead: Manufacturing in regions with high expertise (Italy, Scotland) incurs significantly higher labor costs than in Asia. However, Asian manufacturers with premium capabilities (like some in China) offer a cost balance while maintaining quality.

- Certifications & Testing: The costs of maintaining certifications and conducting rigorous QC are factored into the price.

Navigating Negotiations:

- Be Price-Savvy, Not Just Cheap: An abnormally low quote is a major red flag. Focus on value and total cost of ownership (including quality, consistency, and rework).

- Discuss Volume Tiers: Understand how pricing changes at 500, 1000, and 5000 units. This helps in planning your collection and inventory.

- Clarify Incoterms: Is the quote FOB (Free on Board, you handle shipping and import) or DDP (Delivered Duty Paid, all-inclusive)? This drastically affects landed cost.

- Invest in Sampling: View sampling costs as R&D, not an expense. A perfect sample approved by you is the blueprint for a successful, profitable production run.

Why can two quotes for "cashmere blend scarves" vary so widely?

A 50% difference in quotes is common and usually reflects a difference in material truth and manufacturing standard.

- Quote A (Low): May use recycled cashmere or a high percentage of merino wool, with a micron over 18. Manufacturing might be on older machines with less skilled labor and minimal QC.

- Quote B (High): Specifies virgin, 16-micron Mongolian cashmere blended with silk. Manufactured in a facility with state-of-the-art equipment, rigorous QC, and certifications. The final products will look, feel, and perform as entirely different items. The quote reflects this reality.

Is it possible to produce luxury cashmere blends cost-effectively?

Yes, through strategic sourcing and smart design.

- Source Yarn Directly: Work with a spinner to develop your blend, then ship the yarn to a specialized knitwear factory. This gives you control and can reduce costs compared to buying from a fully integrated mill.

- Consider Asian Manufacturing with Proven Expertise: Countries like China have producers who work directly with Inner Mongolian sources and operate to very high standards, often at a lower cost base than Europe. The key is thorough vetting.

- Optimize Design: Simplify construction where possible. A beautifully finished, simple silhouette in an exquisite fabric often has more luxury appeal than a complex design in a mediocre material.

Conclusion

Finding a supplier for luxury cashmere blends is a deliberate journey into a specialized tier of the textile industry, where quality, provenance, and craftsmanship are paramount. It requires moving beyond simple price comparisons to a deep evaluation of certifications, technical data, manufacturing integrity, and shared values. The right supplier is not a vendor but a custodian of your brand's luxury promise, capable of delivering both the tangible excellence of the material and the intangible assurance of ethical, transparent creation.

By focusing on verifiable quality metrics, investing in rigorous sampling and testing, and partnering with manufacturers whose expertise matches your ambition, you can build a collection that truly embodies luxury. This foundation allows your brand to tell a compelling, authentic story—one of natural beauty, skilled hands, and thoughtful creation—that resonates deeply with the discerning luxury consumer.

If you are embarking on the development of a luxury accessory line with cashmere blends and seek a partner with the technical expertise, sourcing networks, and commitment to quality required for this category, we invite you to connect with us. At Shanghai Fumao Clothing, our team specializes in navigating the complex supply chain for premium natural fibers and transforming them into impeccably crafted finished goods. Let's create something extraordinary together. Contact our Business Director, Elaine, to begin the conversation: elaine@fumaoclothing.com.