You're ready to print your logo on a batch of tote bags or add a vibrant design to your new line of t-shirts. You've heard the terms screen printing and heat transfer, but choosing between them can feel like a technical maze. Each method has its own strengths, cost structures, and ideal applications. Choosing wrong can lead to faded prints, high costs, or a product that doesn't match your brand's quality standard. So, how do you decide which printing technology is right for your fashion accessory or apparel line?

The core difference lies in the process, durability, and suitability for different order quantities and designs. Screen printing involves pushing ink through a woven mesh stencil (a screen) directly onto the fabric, creating a layer of ink on top of the material. Heat transfer (specifically vinyl heat transfer or digital heat transfer) involves first printing a design onto a special carrier paper or vinyl film, which is then transferred onto the fabric using heat and pressure, essentially fusing a layer of plastic or ink film to the garment. Screen printing is renowned for its durability and vibrant color payoff on large runs, while modern heat transfers offer photographic detail and cost-effectiveness for small batches.

Understanding this fundamental distinction is just the beginning. To make the right choice for your production, you need to dive deeper into the types of transfers, the specific feel of each print, the cost breakdown, and which method aligns with your design complexity and product lifecycle. Let's break down each method in detail, from the factory floor to the finished product's performance.

What is the Screen Printing Process and When Should You Use It?

Screen printing is a stencil-based printing method that has been the industry standard for bulk apparel decoration for decades. It's a versatile process that can be used on a wide range of fabrics, but it excels on cotton and cotton-blend textiles.

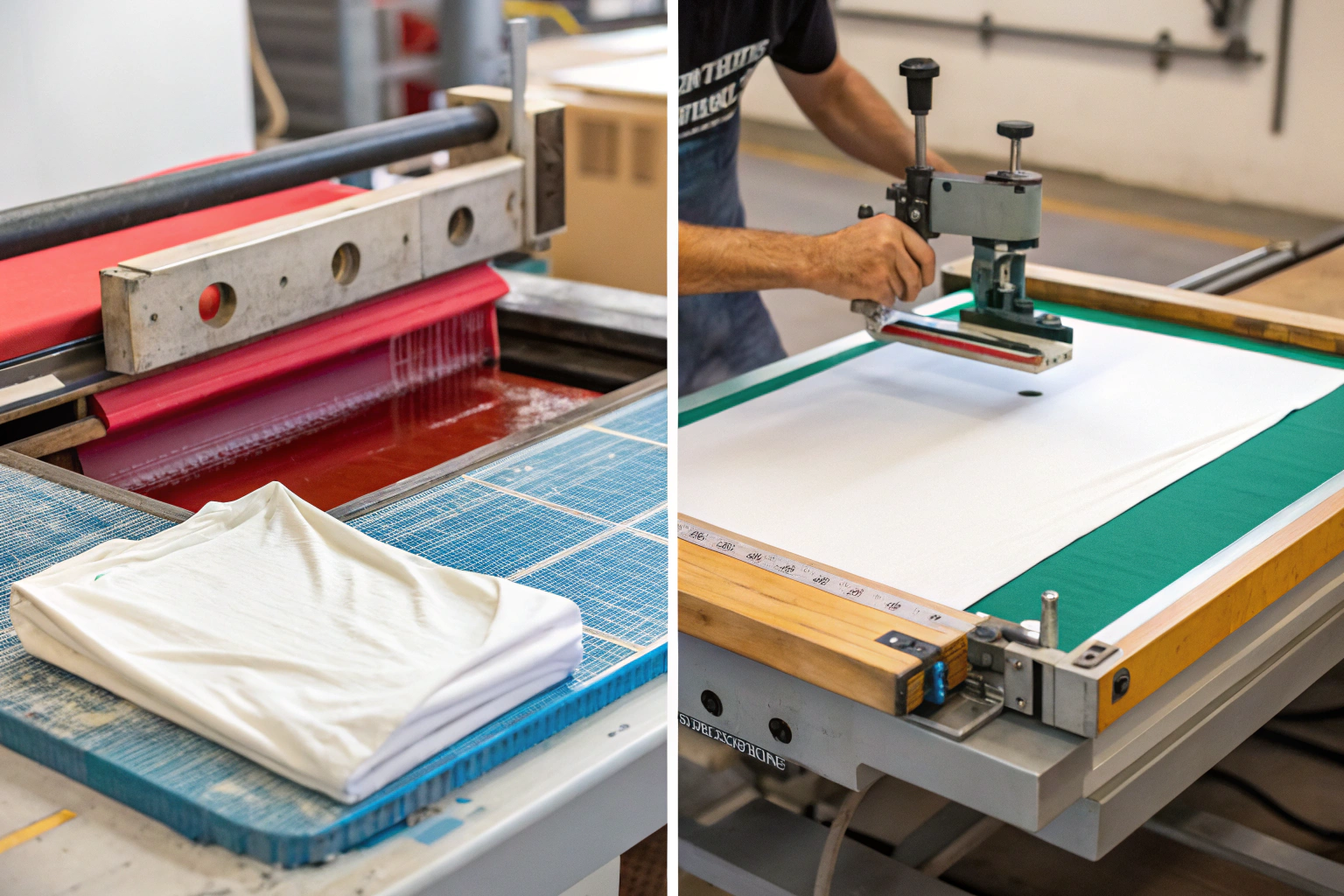

The process is meticulous:

- Separations & Screen Creation: Each color in your design requires a separate film positive and a mesh screen coated with a light-sensitive emulsion. The design is burned onto the screen, washing away the unexposed emulsion to create open areas (your design).

- Setup & Registration: Each color screen is precisely mounted on a carousel press. The garment is placed on a platen, and each screen is aligned (registered) perfectly to build the multi-color design layer by layer.

- Printing & Curing: Ink is poured onto the screen. A squeegee is pulled across, forcing ink through the open mesh onto the garment. After all colors are printed, the garment passes through a conveyor dryer to cure the ink, bonding it to the fabric fibers through heat.

Screen printing is ideal when:

- Order Quantity is High (250+ units): The high setup cost (creating screens) is amortized over many units, making the per-unit cost very competitive.

- Designs Use Limited, Solid Colors: It excels at bold, graphic designs with clear color separations.

- Durability is Paramount: Properly cured plastisol ink (the most common type) is extremely durable, resisting countless washes without cracking or fading.

- You Need Specific Inks: It allows for specialty inks like high-density (for a raised texture), glitter, metallic, or puff inks that add a tactile effect.

For accessory brands, screen printing is perfect for standard logo placement on cotton tote bags, the brim of cotton caps, or uniform designs on scarf borders. Its main limitation is design complexity—highly detailed, photographic images with gradients are challenging and expensive to reproduce, as they require many screens (one for each shade of color). A manufacturer like Shanghai Fumao Clothing will often recommend screen printing for your core, high-volume stock-keeping units (SKUs) where brand consistency and long-term durability are key.

What types of screen printing inks are most common?

The two primary inks are Plastisol and Water-based.

- Plastisol Ink: A PVC-based ink that sits on top of the fabric. It is opaque, vibrant, and easy to work with, offering excellent color consistency. It requires thorough heat curing. It has a slightly rubbery or plastic-like feel, especially on large, solid areas.

- Water-Based Ink: Soaks into the fabric (like a dye), resulting in a much softer, breathable hand-feel. It's preferred for higher-end garments where a "no-feel" print is desired. However, it is less opaque on dark fabrics and can be more challenging to work with, leading to slightly higher costs.

Why is screen printing cost-effective for large orders?

The cost structure is front-loaded. The significant expense is in the one-time setup: creating the film positives and screens for each color. Once this is done, the marginal cost of printing each additional garment is relatively low (just ink, labor, and overhead). Therefore, the more units you print, the lower the cost per unit becomes. For a run of 1,000 shirts, screen printing is almost always cheaper per piece than any transfer method.

What Are the Different Types of Heat Transfer and Their Applications?

"Heat transfer" is an umbrella term for several techniques where a design is first created on a carrier and then applied with heat. The two most relevant types for fashion accessories are Vinyl Heat Transfer and Digital/Direct-to-Film (DTF) Transfer. They serve very different purposes.

1. Vinyl Heat Transfer (HTV): This uses pre-colored, solid sheets of plastic vinyl (like PVC or polyurethane) that are cut into shapes by a plotter. The excess vinyl is weeded away, leaving the design on a carrier sheet. It is then heat-pressed onto the garment.

- Best For: Simple, single-color logos, numbers, or text. Think team jerseys, workwear logos, or minimalist designs.

- Feel: Creates a raised, plastic-like layer on the fabric. It can be stiff, though thinner "flex" vinyls are better for stretchy fabrics.

- Durability: Very durable if applied correctly, but the vinyl layer can eventually crack or peel with extreme stretching or abrasion.

2. Digital Heat Transfer (Inkjet Transfer & DTF): This is where the technology has advanced dramatically.

- Inkjet Transfer Paper: A full-color design is printed onto a special coated paper using a standard inkjet printer (with specialized inks). This paper is then heat-pressed onto the garment, transferring the ink layer.

- Direct-to-Film (DTF): The modern frontrunner. A design is printed with pigment inks onto a clear, adhesive-coated plastic film. A layer of hot-melt powder is applied to the wet ink, then melted to create an adhesive layer. The entire print on the film is then transferred to the garment under heat and pressure.

- Best For: Photographic designs, full-color graphics, gradients, and small batches. It works brilliantly on a wide range of fabrics, including cotton, polyester, and blended materials.

- Feel: DTF offers a softer, more flexible finish than traditional vinyl. The print is thin and breathable.

- Durability: Excellent wash durability, rivaling screen printing when done correctly.

For accessory brands, DTF transfers are a game-changer. They allow for on-demand production of complex, all-over prints on bucket hats, detailed patches for bags, or small runs of tech-focused accessories without the setup cost of screens. It's ideal for testing new designs, producing limited editions, or personalizing items. However, for simple, one-color logos on thousands of units, vinyl or screen printing will be more cost-effective.

What is the key advantage of DTF over traditional inkjet transfers?

DTF (Direct-to-Film) solves the major drawbacks of old-school inkjet transfers. Traditional transfers often had a stiff, plastic-like hand-feel and a visible "transfer border." DTF uses a fine powder adhesive that, when melted, creates a thin, flexible, and breathable layer. The print is more vibrant, has better wash durability, and leaves no plastic residue or border feel on the fabric. It essentially bridges the gap between the detail capability of digital printing and the durability of screen printing.

Can heat transfers be used on all materials?

Not universally, but the range is broad. The key is matching the transfer type to the fabric:

- Vinyl (HTV): Works best on cotton, polyester, and blends. Requires the correct temperature and pressure settings for the specific material. Not ideal for delicate or heat-sensitive fabrics like nylon or rayon.

- DTF Transfers: Highly versatile. They adhere well to cotton, polyester, nylon, canvas, and even leather (with adjusted settings). They are particularly strong on poly-blends because the adhesive bonds well with synthetic fibers.

Always conduct a test application on the exact production fabric before committing to a full order.

How Do Print Feel, Durability, and Cost Compare Side-by-Side?

Choosing between screen print and heat transfer often comes down to a trade-off between hand-feel, longevity, design complexity, and economics. Here’s a direct comparison to clarify the decision matrix.

| Feature | Screen Printing | Heat Transfer (Vinyl) | Heat Transfer (DTF) |

|---|---|---|---|

| Best For | Large orders, bold graphics, high durability. | Simple 1-2 color designs, sportswear, small logos. | Complex designs, photos, gradients, small-medium batches. |

| Design Complexity | Limited by color count. Gradients are difficult. | Simple shapes and text only. | Unlimited colors, photorealistic detail. |

| Hand-Feel | Plastisol: Slightly raised, rubbery. Water-based: Soft. | Raised, plastic-like, can be stiff. | Thin, flexible, relatively soft ("no-feel" is possible). |

| Durability | Excellent. Withstands many industrial washes. | Good. Can crack or peel with extreme stress over time. | Very Good to Excellent. High-quality DTF rivals screen print. |

| Fabric Versatility | Best on cotton. Works on blends. | Cotton, polyester, blends. | Very High. Cotton, polyester, nylon, blends, canvas. |

| Setup Cost | High (per color screen). | Low to Medium (digital file setup & cutting). | Low (digital file setup only). |

| Cost per Unit (Low Qty) | High (due to setup). | Medium. | Low. |

| Cost per Unit (High Qty) | Very Low. | High (labor-intensive weeding). | Medium. |

| Turnaround Time | Longer (setup required). | Fast for simple designs. | Very Fast (no color separations). |

| Environmental Impact | Plastisol ink is plastic-based. Water-based is more eco-friendly. | PVC vinyl is not biodegradable. | Pigment inks and polymers have an impact; less waste than screen cleaning. |

The Verdict:

- Choose Screen Printing for your high-volume, core product line where you need maximum durability and a classic print look (e.g., standard logo t-shirts, uniform caps, promotional tote bags).

- Choose DTF Heat Transfer for low-to-medium volume runs, complex designs, or product testing. It's also superior for all-over-printing on items like hats or bags where screen printing would be impractical.

- Choose Vinyl Transfer for simple, durable emblems on performance wear or workwear where a rugged, raised logo is acceptable or desired.

How does the "hand-feel" impact customer perception?

The hand-feel—the tactile sensation of the print—directly influences perceived quality. A stiff, plastic-like print (from cheap vinyl or thick plastisol) can feel cheap and uncomfortable, especially on items worn close to the skin like t-shirts. A soft, breathable print (from high-quality water-based screen printing or DTF) feels premium and is often associated with higher-end brands. For lifestyle and fashion accessories, prioritizing a soft hand-feel is crucial for customer satisfaction and repeat business.

What are the hidden costs or risks with each method?

- Screen Printing: Risk of registration errors (colors misaligned) on press. Ink opacity issues on dark garments requiring an underbase, which adds a screen and cost. Environmental cost of screen reclamation (chemicals used to clean screens).

- Heat Transfer (Vinyl): Labor-intensive weeding for complex designs drives up cost. Risk of peeling or cracking if not applied with perfect time, temperature, and pressure. Limited design aesthetic.

- Heat Transfer (DTF): Printer and powder consistency is vital; low-quality materials lead to poor durability. The whiteness of the garment can affect color vibrancy on dark fabrics (often requiring a white underbase layer, which DTF can do). Slightly higher per-unit material cost than screen printing at very high volumes.

Which Method is Best for Your Specific Product and Business Stage?

Your choice isn't just about the print; it's about your business model, growth stage, and product mix. Here’s how to align the technology with your strategy.

For Startups & Product Launches:

- Recommendation: DTF Heat Transfer.

- Why: Minimal setup cost and no minimum order quantity (MOQ) allow you to test the market with small batches of multiple designs. You can achieve professional, full-color prints without a large capital outlay. It allows for maximum creative flexibility as you refine your brand identity.

For Established Brands with Core SKUs:

- Recommendation: Screen Printing for core items, DTF for limited editions.

- Why: For your best-selling, evergreen products (e.g., your signature logo tee), screen printing offers the lowest cost per unit and proven durability at scale. Use DTF to create seasonal variations, artist collaborations, or limited-run designs without the screen cost, keeping your lineup fresh.

For Accessories Beyond Apparel:

- Consider the substrate: The choice expands.

- Tote Bags & Backpacks (Canvas/Cotton): Screen printing is excellent for durability. DTF is great for detailed, all-over prints.

- Hats (Structured, curved surface): DTF is often superior because it can conform to curved seams and panels more easily than a flat screen. Vinyl is common for simple front-panel logos on baseball caps.

- Tech Accessories (Phone Cases, Laptop Sleeves): DTF or specialized UV printing on hard surfaces. Screen printing is not suitable.

Partnering with the Right Manufacturer: A full-service manufacturer like Shanghai Fumao Clothing will have both capabilities in-house. They can provide objective advice based on your design files, order quantity, and target cost, often producing physical strike-offs (sample prints) in both methods so you can see and feel the difference before committing. This partnership is invaluable for making a cost-effective, quality-driven decision.

Should you mix printing methods in one product line?

Absolutely. This hybrid approach is smart business. Use screen printing for your high-volume, price-sensitive basics. Use DTF transfers for your premium, detailed, or limited-edition pieces that command a higher price point. This optimizes your cost structure and allows you to cater to different customer segments within your brand.

How do you brief your manufacturer on print specifications?

Provide a clear tech pack that includes:

- Vector Artwork: For screen printing or vinyl, provide vector files (AI, EPS) with each color on a separate layer.

- High-Resolution Raster Artwork: For DTF, provide a 300 DPI PNG or PSD file with a transparent background.

- Pantone Color Codes: Specify exact colors for screen printing.

- Mockup & Placement: A visual mockup showing exactly where and how large the print should be.

- Fabric Composition: Specify the exact material of the product to be printed.

- Quantity: Your estimated order quantity for each design.

With this information, your manufacturer can provide an accurate quote and recommendation.

Conclusion

The choice between screen printing and heat transfer is not about which technology is universally better, but about which is optimal for your specific design, product, order volume, and quality requirements. Screen printing remains the unbeaten champion for durable, cost-effective bulk production of graphic designs. Modern DTF heat transfer has revolutionized the field, making photographic quality and small-batch agility accessible to brands of all sizes.

By understanding the tactile feel, cost dynamics, and durability profile of each method, you can make an informed decision that protects your brand's quality perception, manages your production budget, and delivers a product your customers will love and wear for years to come. The most successful brands often leverage a strategic mix of both technologies across their collections.

If you are developing custom printed accessories and want expert guidance on selecting the perfect print method for your designs, we are here to help. At Shanghai Fumao Clothing, we operate both advanced screen printing and DTF transfer lines, allowing us to provide unbiased recommendations and high-quality samples. Let's ensure your prints are perfect. Contact our Business Director, Elaine, to discuss your project: elaine@fumaoclothing.com.