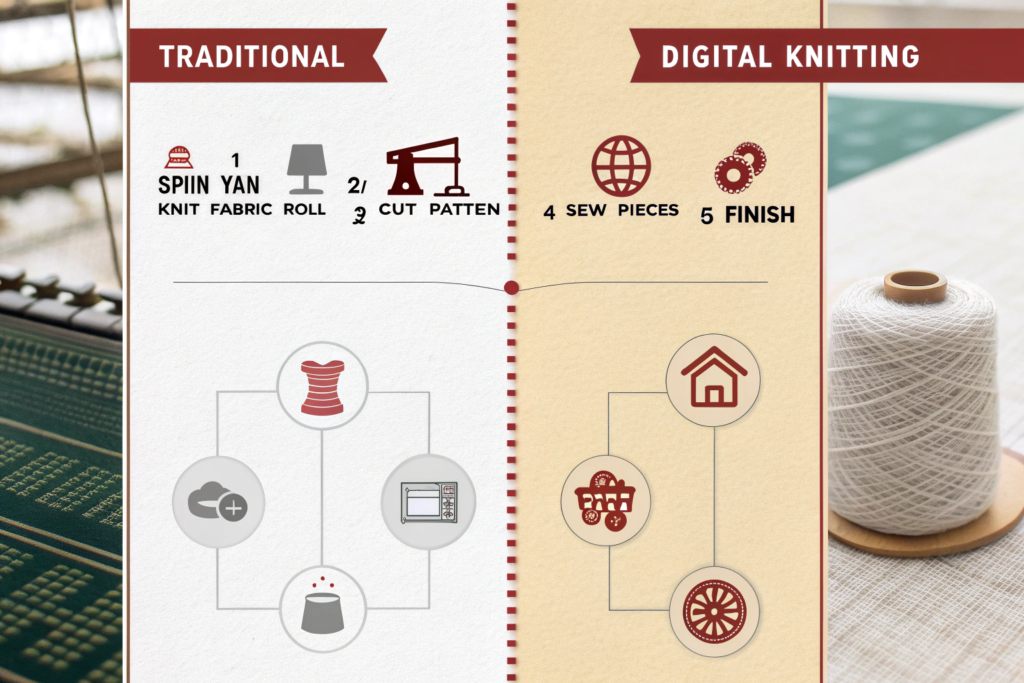

Are you still designing scarves, hats, and gloves with traditional cut-and-sew methods, dealing with fabric waste and long lead times? Have you wondered how brands create seamless, intricate, and custom-knit accessories with such precision and speed? You're looking at the transformative power of digital knitting. This isn't your grandmother's knitting machine; it's a computer-controlled, additive manufacturing process that is revolutionizing soft goods production, especially for accessories where detail, fit, and sustainability are paramount.

Digital knitting (also known as computerized flat knitting or 3D knitting) uses software to program industrial knitting machines (like those from Shima Seiki or Stoll) to create complete, finished products or panels with minimal to zero manual assembly. The advantages are profound, moving production from a subtractive, labor-intensive model to an integrated, efficient, and highly creative one. For accessory brands, this technology unlocks unprecedented possibilities in design, customization, and responsible manufacturing.

This guide will detail the key benefits driving adoption. We'll explore the unmatched design complexity and customization it enables, the significant gains in sustainability and efficiency, the superior product performance and fit it delivers, and the strategic implications for brands looking to innovate and streamline their supply chain. Let's unravel the future of knit accessories.

How Does Digital Knitting Enable Unmatched Design Complexity?

Traditional knitting and cut-and-sew are limited by the skill of the operator and the practicality of assembly. Digital knitting removes these barriers by translating a digital file directly into a physical product. The design possibilities are virtually limitless, constrained only by the software and the machine's gauge (needle fineness).

Key Design Advantages:

- Complex, Seamless 3D Shapes: Machines can knit complete products—like a seamless glove, a hat with integrated crown shaping, or a sock—in one continuous piece, eliminating side seams that can cause discomfort and weak points. This is the technology behind popular seamless touchscreen gloves.

- Intricate Colorwork and Intarsia: Switching yarn colors pixel-by-pixel allows for photorealistic patterns, intricate logos, and complex jacquards without the need for printing or embroidery. Each stitch can be a different color.

- Integrated Textures and Structures: Within a single product, you can program zones with different knit structures: ribbed cuffs for elasticity, mesh panels for breathability, and double-knit sections for warmth—all knitted simultaneously.

- Variable Gauge and Stitch Density: The software can control individual needles to create areas that are denser (more wind-resistant) or looser (more stretchy), optimizing performance in specific zones of an accessory.

This level of design integration is impossible with traditional methods and allows for true "engineered" knitwear.

Can You Create Custom, On-Demand Designs at Scale?

Absolutely. This is one of its most disruptive advantages. The "recipe" for a product is a digital file (.knit). Changing a color, altering a pattern, or personalizing with a name or logo is as simple as modifying the digital design and sending it to the machine. This makes mass customization and made-to-order production economically viable. A brand could offer customers the ability to customize the colorway of a beanie online, and the machine knits that single, unique order with zero additional setup cost for new patterns. This agility responds directly to the demand for personalized products.

How Does It Compare to Traditional Knit and Sew?

| Aspect | Traditional Cut-and-Sew / Hand-Knitting | Digital Knitting (3D/Whole Garment) |

|---|---|---|

| Design Flexibility | Limited by pattern pieces and assembly. | Near-infinite; complex 3D shapes and integrated details. |

| Lead Time | Longer (fabric production, cutting, bundling, sewing). | Shorter (direct from yarn to near-finished product). |

| Material Waste | High (15-30% from cutting). | Extremely Low (under 5%, often near-zero). |

| Labor Intensity | High (multiple sewing operators). | Low (machine operation, minimal finishing). |

| Consistency | Variable, depends on operator skill. | Pixel-perfect, consistent across units. |

What Are the Sustainability and Efficiency Gains?

In an industry under pressure to reduce its environmental footprint, digital knitting presents a compellingly cleaner production model. Its efficiency isn't just about speed; it's about radically reducing waste and streamlining the supply chain.

Core Sustainability & Efficiency Benefits:

- Dramatic Reduction in Material Waste: This is the headline benefit. Because the product is knit-to-shape, there are no fabric cuttings ending up as scraps. The machine uses only the yarn needed for the product itself. This can reduce material waste from over 20% to less than 5%, and in whole-garment knitting, to near 0%.

- Simplified Supply Chain & Inventory: The process collapses multiple steps (yarn -> fabric -> cutting -> sewing) into one (yarn -> finished product). This means less inventory of semi-finished goods, fewer suppliers to manage, and reduced complexity.

- On-Demand & Localized Production: The small physical footprint and quick reprogrammability of digital knitting machines make them ideal for micro-factories or on-shoring. Brands can produce closer to their market, reducing carbon emissions from shipping and reacting faster to trends.

- Energy Efficiency: While machines use electricity, the elimination of multiple transport and processing stages (fabric milling, dyeing, cutting) can lead to a lower overall carbon footprint per item.

For brands building a credible sustainability story, this technology is a tangible, marketable advancement.

Is Digital Knitting Compatible with Sustainable Yarns?

Yes, seamlessly. The machines can knit with a vast range of yarns, including:

- Recycled Yarns: rPET (from plastic bottles), recycled cotton.

- Natural & Organic Yarns: GOTS-certified organic cotton, merino wool, linen blends.

- Innovative Biodegradable Yarns: Tencel™ Lyocell, etc.

This means you can combine the waste-free manufacturing process with eco-conscious materials for a truly low-impact product. The ability to use delicate or expensive specialty yarns with minimal waste makes it economically feasible to work with premium sustainable materials.

How Does It Improve Production Speed and Responsiveness?

The speed advantage comes from integration and elimination of bottlenecks. A digitally knit hat might be completed in minutes on the machine, with only light trimming and washing needed afterward. There's no waiting for fabric to be knitted, dyed, and delivered to a cutter. For new designs, once the digital file is perfected, production can begin immediately—no waiting for physical patterns or cutting dies. This allows for faster prototyping and the ability to do small-batch, test-market production with minimal financial risk, a key strategy for managing trend-driven inventory.

How Does It Enhance Product Performance and Fit?

Beyond aesthetics and sustainability, digital knitting creates functionally superior products. By engineering the knit structure at the stitch level, you can optimize the accessory for its specific purpose.

Performance and Fit Enhancements:

- Seamless Construction: Eliminating seams removes points of friction, irritation, and potential failure. This is critical for items like gloves, socks, and headbands where comfort against the skin is paramount. It also improves wind and water resistance by removing needle holes from seams.

- Engineered Fit and Compression: The software can program graduated compression or specific elasticity into different areas. For example, a sport headband can have a tighter, sweat-wicking knit at the brow and a looser, breathable knit elsewhere.

- Integrated Functional Zones: As mentioned, you can create ventilation meshes, padded protective zones, or conductive fingertip patches for touchscreen capability directly within the knit, without adding layers or separate components.

- Consistent, Precise Dimensional Control: Every product is an exact replica of the digital file, ensuring perfect size consistency across an entire production run. This drastically reduces returns due to sizing issues, a common headache with traditional cut-and-sew apparel.

Can It Replicate Hand-Knit or Artisanal Looks?

Yes, with stunning accuracy. Advanced software can simulate the nuances of hand-knit stitches, including cable knits, fisherman's ribs, and brioche stitches. While purists will note the difference, to the consumer's eye, digital knitting can produce accessories with a rich, artisanal texture at a fraction of the time and cost of true hand knitting. This allows brands to offer "craft" aesthetics at a scalable, accessible price point.

What are the Limitations or Challenges of the Technology?

It's not a panacea. Key considerations include:

- High Initial Investment: The machines are expensive, often limiting access to larger manufacturers or specialized contractors.

- Yarn Limitations: While versatile, machines have constraints on yarn thickness, elasticity, and fiber type that must be carefully tested.

- Design Expertise Required: Creating the digital knit programs requires specialized software skills (like using SDS-ONE APEX or M1+), which is different from graphic or fashion design.

- Minimum Order Quantities (MOQs): While lower than traditional cut-and-sew for complex items, there are still practical MOQs for yarn sourcing and machine setup time.

These challenges mean partnering with an experienced manufacturer is crucial.

What Does This Mean for Accessory Brands and Sourcing?

Adopting digital knitting requires a shift in strategy, from sourcing finished goods to collaborating on digital product creation. It favors brands that value innovation, speed, and sustainability.

Strategic Implications:

- Partner with Specialists: Look for factories that advertise "3D knitting," "whole garment knitting," or "digital knitwear" capabilities. They will have the machines and, critically, the programming expertise.

- Rethink Design Workflow: Your design process starts in knit simulation software, not on a sketchpad. You'll approve a digital prototype that simulates drape and structure before any yarn is used.

- Embrace New Business Models: Explore made-to-order, limited editions, or personalized accessories to leverage the technology's flexibility.

- Costing is Different: The cost model shifts from fabric + labor to yarn + machine programming/run time. For complex items, it can be cost-competitive or cheaper; for very simple items, traditional methods may still win.

A forward-thinking manufacturer like Shanghai Fumao Clothing invests in such technologies or partners with specialized knitters to offer these advanced solutions to innovative brands.

How to Start a Project with a Digital Knitting Manufacturer?

- Begin with a Concept & Yarn Brief: Define your product (e.g., a seamless neck gaiter) and desired yarn (e.g., a merino wool blend for warmth and wicking).

- Request a Feasibility Study: The manufacturer will analyze the design, recommend yarns, and provide a cost/time estimate.

- Develop the Digital Knit Program: This is the equivalent of your "mold" or "pattern." You will approve a digital simulation.

- Prototype & Sample: The factory will knit physical samples for fit, feel, and function testing. Iterate as needed.

- Production: Once the digital file is approved, production runs are highly automated and consistent.

Is Digital Knitting the Future of All Knit Accessories?

While it won't replace all traditional methods overnight, it is undoubtedly the future direction for high-performance, complex, and sustainably-focused knit accessories. As the technology becomes more accessible and yarn options expand, its share of the market will grow exponentially. Brands that adopt it early will gain a significant competitive edge in design innovation, supply chain resilience, and environmental credentials.

Conclusion

Digital knitting technology offers a transformative suite of advantages for fashion accessory production: unparalleled design freedom with complex 3D shapes and intricate patterns, radical reductions in material waste aligning with circular economy goals, superior product performance through seamless construction, and a streamlined, responsive supply chain.

For accessory brands, this represents a powerful tool to differentiate, innovate, and produce more responsibly. It shifts the paradigm from manufacturing to digital creation, opening up new possibilities for customization and efficiency. Embracing this technology is an investment in a more agile, creative, and sustainable future.

Ready to explore the potential of digital knitting for your next accessory line? At Shanghai Fumao Clothing, we connect our clients with cutting-edge digital knitting specialists within our network. We can manage the entire development process, from concept and yarn sourcing to digital file approval and production. Contact our Business Director Elaine at elaine@fumaoclothing.com to knit your vision into reality.