Are you looking to source or produce reusable textile masks that meet stringent medical or high-performance protection standards? Do terms like "ASTM F3502," "BFE," and "Level 3" feel like a regulatory maze when trying to vet potential manufacturers? You're entering a highly specialized field where the margin for error is zero. A "medical-grade" claim is not a marketing term; it's a certification-backed promise of performance and safety. Finding the right manufacturer requires targeting factories with specific competencies in regulated medical textiles, not just general apparel cut-and-sew.

The key is to identify partners who operate within a Quality Management System (QMS) framework, understand material performance testing, and can navigate the regulatory landscape for the target market (e.g., FDA, CE marking, HSA). This goes far beyond sewing skills. You need a manufacturer with a documented process for material validation, in-process controls, and final product testing to ensure every mask meets the claimed standard.

This guide provides a step-by-step due diligence process. We'll cover how to identify factories with medical textile expertise, evaluate their technical and compliance capabilities, navigate the critical sampling and validation phase, and finally, establish the quality agreements necessary for a reliable supply chain. Let's build a supply chain for protection you can trust.

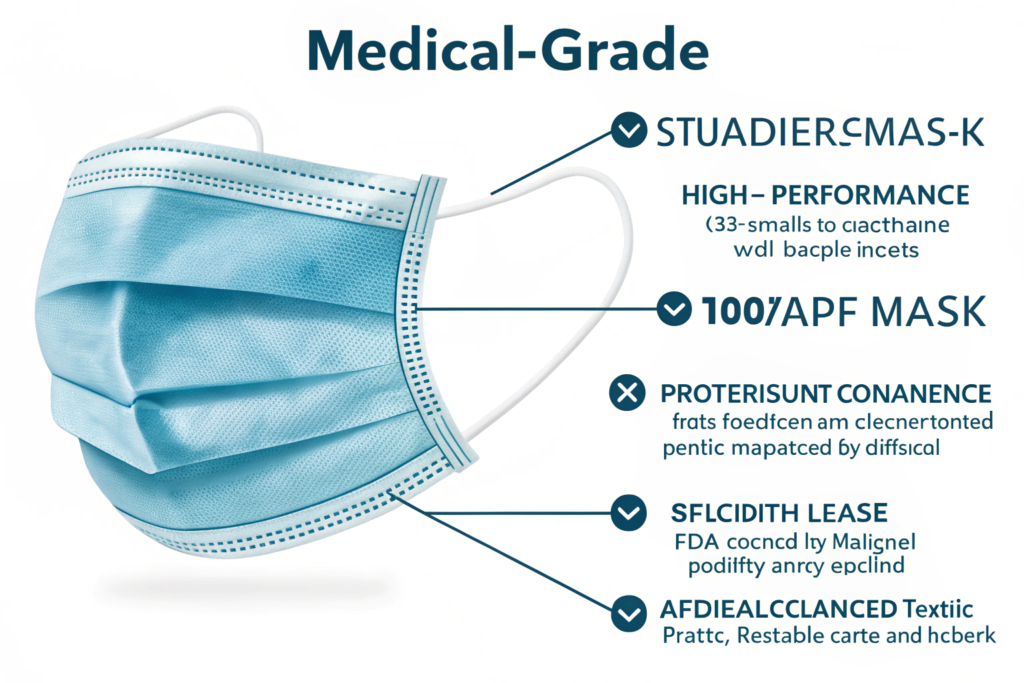

What Defines a "Medical-Grade" Textile Mask Manufacturer?

First, clarify the terminology. "Medical-grade" often refers to masks intended for use in healthcare settings or as high-performance personal protective equipment (PPE). For reusable textile masks, the benchmark is typically compliance with a recognized performance standard, not necessarily FDA 510(k) clearance (which is for surgical masks). The manufacturer's capability is defined by their ability to consistently produce to these standards.

Core Competencies to Look For:

- Regulated Mindset: The factory should have ISO 13485 certification (Medical Devices - Quality Management Systems) or at the very least, be operating under a robust QMS with strict document control and traceability.

- Material Science Knowledge: They must understand and source certified materials—not just any fabric. This includes approved non-woven filtration media (e.g., meltblown polypropylene with BFE/PFE ratings), hydrophobic outer layers, and skin-friendly inner liners. They should have relationships with reputable material suppliers who provide Lot-Specific Test Reports.

- Controlled Environment: While not always a full cleanroom, production should occur in a very clean, controlled environment to minimize particulate contamination. Separate areas for material storage, cutting, assembly, and packaging are essential.

- In-House Testing & QC: They should perform incoming inspection on all materials against spec sheets and have the capability for in-process checks (e.g., ultrasonic weld strength, stitch integrity) and final product sampling tests.

What is the Difference Between ISO 13485 and ISO 9001?

This is a critical distinction.

- ISO 9001: A general quality management standard applicable to any industry. It focuses on customer satisfaction and continuous improvement.

- ISO 13485: A medical device-specific QMS standard. It has far stricter requirements for risk management, document control, traceability, and validation of processes. A factory with ISO 13485 certification is demonstrating a commitment to the regulatory rigor required for medical products. It is the strongest indicator of a suitable partner.

Do You Need a Factory that Produces "Surgical Masks" or "Respirators"?

Understand your product category:

- Surgical Masks (ASTM F2100): Disposable, regulated medical devices. Manufacturing requires significant regulatory submissions (like FDA 510(k)) and is highly specialized. This is likely not your target for reusable textiles.

- Barrier Face Coverings (ASTM F3502): This is the key standard for reusable textile masks in the US market. It defines performance levels for filtration efficiency and breathability. Your manufacturer must understand this standard and how to engineer a product to meet it.

- Respirators (e.g., N95, KN95, FFP2): These are tight-fitting, disposable filtering facepiece respirators with very specific NIOSH or equivalent certifications. Again, different from reusable textiles.

Target factories that explicitly mention ASTM F3502, BFE/PFE testing, or barrier face coverings.

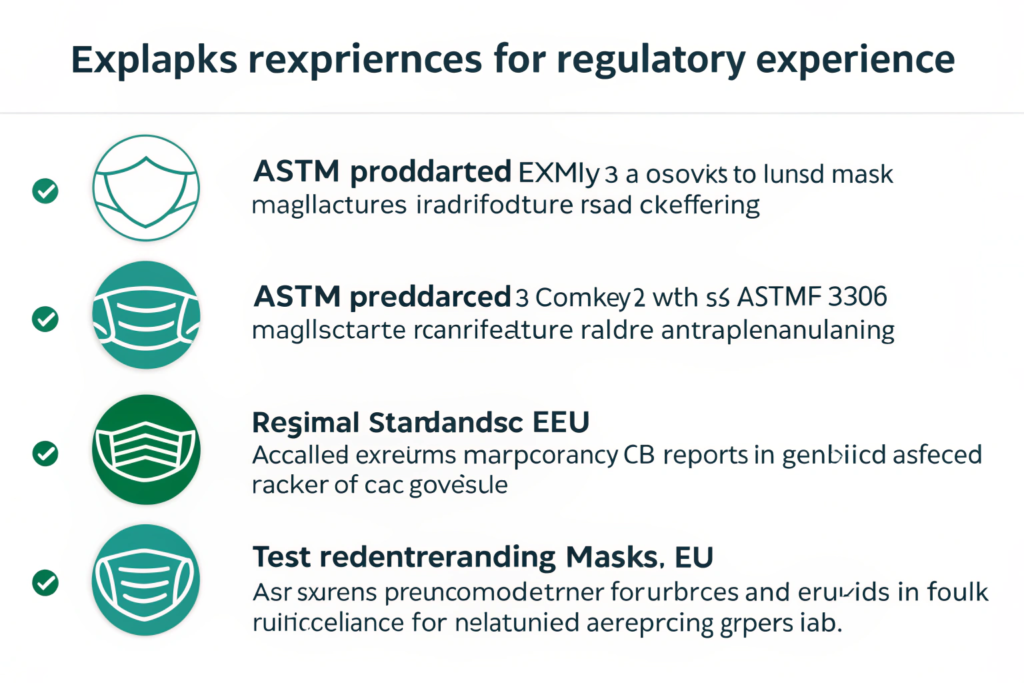

How to Vet a Factory's Technical and Compliance Capabilities?

Due diligence for a medical textile manufacturer is intensive and must be evidence-based. Move beyond sales pitches to request concrete documentation and conduct structured audits.

The Request for Information (RFI) Checklist:

- Certifications: Copies of ISO 13485 or other relevant quality certificates.

- Facility & Process Overview: Request a diagram of their production flow and QC checkpoints. Ask for photos/videos of the production floor.

- Material Supply Chain: Ask for a list of their approved material suppliers for filtration layers, fabrics, nose wires, and elastics. Request sample Material Test Reports from these suppliers.

- Testing Equipment & Protocols: What in-house testing do they perform? (e.g., do they have a breathability tester? Do they send samples to a third-party lab?) Ask for a sample QC inspection report.

- Regulatory Experience: Ask for examples of masks they have produced that comply with ASTM F3502, EN 14683 (EU), or other regional standards. Request redacted copies of the test reports from an accredited lab for those products.

A manufacturer that is transparent and prompt in providing this information is a positive sign.

What Should a Factory Audit Cover for This Product?

If possible, conduct an on-site or virtual audit. Focus on:

- Material Warehouse: Is material stored properly (away from moisture, contaminants)? Is it clearly labeled with lot numbers?

- Production Line: Is the area clean and organized? Are operators wearing appropriate attire (hairnets, gloves if needed)?

- Quality Stations: Are there dedicated QC stations with measurement tools, lightboxes for visual inspection, and documented checklists?

- Documentation: Review their Device History Record (DHR) template. Every batch of finished masks should have a DHR that traces materials used, production dates, QC results, and final approval.

- Sterilization/Packaging (if applicable): If making sterile masks, their sterilization process (e.g., ethylene oxide, gamma irradiation) and packaging validation are critical.

This level of scrutiny is more akin to vetting a pharmaceutical supplier than a fashion accessory maker.

How to Verify Their Claims with Third-Party Lab Reports?

Never take performance claims at face value. The ultimate verification is a third-party test report from an accredited laboratory (e.g., Nelson Labs, SGS, Intertek, TÜV).

- Action: For any pre-existing mask style they offer, request the full test report.

- Review: Check the report's authenticity (lab logo, signatures), the test standard used (e.g., ASTM F3502-21), the sample description (does it match the product?), and the results. Look for key metrics: Filtration Efficiency (FE) Level, Breathability (Delta P), and Flow Rate.

If they cannot provide this for existing products, it is a major red flag.

How to Navigate the Sampling and Validation Phase?

The sampling phase for a medical-grade product is not about aesthetics; it's about performance validation and process verification. This is a multi-stage, data-driven endeavor.

The Critical Path for Sampling:

- Design Input & Tech Pack: Create an exhaustive tech pack specifying every material by brand, grade, and performance specification (e.g., "32gsm SMS non-woven, BFE ≥98%"), along with precise construction details (stitch type, weld parameters).

- Prototype Samples (Engineering Samples): The factory produces initial samples using the specified materials. These are not for sale; they are for fit, form, and function checks.

- Lab Testing & Design Verification: Send these prototypes to your chosen accredited lab for formal testing against the target standard (e.g., ASTM F3502). This report validates that your design can meet the standard.

- Pre-Production (Validation) Samples: Once the design is verified, the factory produces samples using the exact mass production process. A larger batch of these are used for process validation.

- Performance Consistency Testing: Multiple units from the validation batch are tested to ensure consistency. This step proves the manufacturing process can reliably produce to spec.

Only after successful completion of these steps should you approve mass production.

What are the Key Tests in Standards Like ASTM F3502?

Understand what you are testing for:

- Filtration Efficiency (FE): Measures the percentage of particles (e.g., 0.3 micron) filtered. ASTM F3502 defines Level 1 (≥20% FE) and Level 2 (≥50% FE) for barrier face coverings.

- Breathability (Delta P, or Pressure Differential): Measures airflow resistance. Lower Delta P means easier breathing. The standard sets maximum Delta P limits.

- Flow Rate: Evaluates performance during inhalation/exhalation.

- Flammability: Must pass applicable flammability tests.

Your lab report will show pass/fail against these criteria. The manufacturer must understand how material choices and construction affect these results.

Who is Responsible for Lab Testing Costs and Logistics?

Typically, the brand/buyer bears the cost and manages the relationship with the third-party lab. This ensures independence and control over the testing process. You select the lab, ship the samples, and receive the reports directly. The factory's role is to provide the samples to your specification and, if they fail, to work with you to analyze the cause (e.g., material issue, construction flaw) and revise. Budget for multiple rounds of testing; it is a non-negotiable cost of product development in this category.

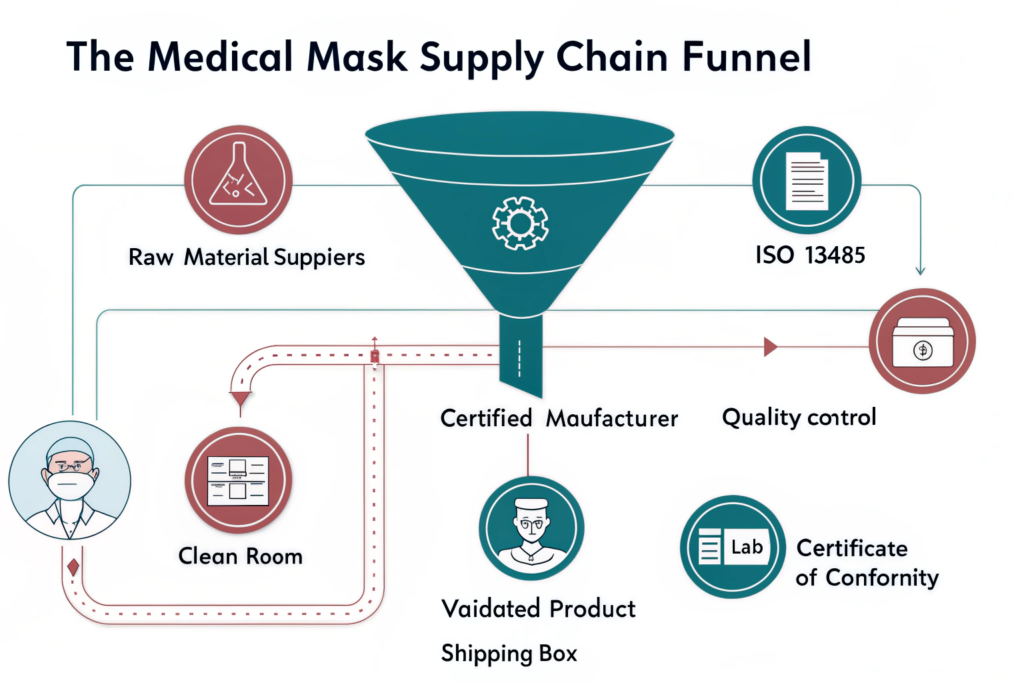

How to Establish a Quality Agreement and Manage Production?

A standard purchase order is insufficient. You need a formal Quality Agreement that outlines the responsibilities of both parties and defines the requirements for production and release. This is your contractual quality control.

Essential Elements of a Quality Agreement:

- Specifications & Standards: Explicitly reference the approved tech pack and the compliance standard (e.g., "Product shall meet all requirements of ASTM F3502 Level 2").

- Material Controls: The factory must not change material suppliers or grades without your written approval and re-validation.

- Production & QC Requirements: Detail the required in-process checks, sampling plans, and final inspection criteria (often based on AQL for visual defects, but with 100% functional checks if possible).

- Lot Traceability & Documentation: Each shipping lot must have a unique lot number and be accompanied by a Certificate of Conformity (CoC) and a summary of the Device History Record (DHR).

- Non-Conformance & Corrective Action: Define the process for handling failed inspections or defective products.

- Audit Rights: You retain the right to audit the factory and its sub-suppliers with reasonable notice.

This agreement aligns expectations and provides legal recourse, a necessity when product failure carries significant risk.

What is the Role of a "Certificate of Conformity" (CoC)?

For every shipment, the manufacturer must issue a CoC. This document states that the products in the specified lot were manufactured in accordance with the agreed Quality Agreement and meet the declared performance standard. It should be signed by an authorized quality representative of the factory. This CoC, along with the underlying lab test reports, forms your technical file for market regulatory compliance and customer assurance.

How to Handle Post-Market Surveillance and Complaints?

Establish a protocol. The factory must notify you immediately of any material or process-related issues discovered post-shipment. You are responsible for tracking customer complaints and potential failures. If a trend indicates a manufacturing defect, the Quality Agreement should define the recall or corrective action process, including cost responsibility. This proactive lifecycle management is a core tenet of medical device regulation.

Conclusion

Finding a manufacturer for medical-grade textile masks is a rigorous process of identifying partners with the right regulatory mindset, technical expertise, and quality systems. It requires moving beyond apparel sourcing to target factories with ISO 13485 certification, proven experience with performance standards like ASTM F3502, and a transparent, document-driven culture.

Success depends on thorough vetting, a data-driven sampling and validation phase managed with independent labs, and the establishment of a formal Quality Agreement. This disciplined approach ensures your masks deliver on their promise of protection, safeguarding both end-users and your brand's integrity.

Ready to partner with a manufacturer equipped for regulated textile production? At Shanghai Fumao Clothing, while our core is fashion accessories, our network includes specialized partners in regulated textile production. We can facilitate introductions and help manage the critical path of specification, validation, and quality oversight for your project. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your requirements.