Are you sourcing umbrellas but worried the fabric won't actually protect customers from harmful UV rays? Do terms like "UPF 50+" feel like marketing claims without substance? You're right to be cautious. An umbrella marketed as "UV resistant" that fails can lead to sunburn, damaged brand trust, and even liability issues. True UV resistance is a measurable, engineered property, not an inherent trait of most fabrics.

Ensuring UV resistance requires a proactive, verification-based approach that starts at the fabric sourcing stage and continues through testing and labeling. It involves selecting the right base materials, understanding and specifying the correct treatment processes, and demanding certified proof of performance. You cannot rely on color or thickness alone as indicators.

This guide will provide a clear, actionable framework. We'll cover how UV protection is measured (UPF ratings), the roles of fabric composition, construction, and color, the different types of UV-blocking treatments and coatings, and the critical step of third-party testing and certification. Let's make sure your umbrellas provide real shade and real protection.

How is UV Resistance Measured and Rated?

The first step is understanding the metric. UV protection for fabrics is measured as Ultraviolet Protection Factor (UPF), not SPF (which is for sunscreen). UPF indicates how much UV radiation (both UVA and UVB) a fabric blocks from reaching the skin.

Key UPF Ratings:

- UPF 15-24: Good protection.

- UPF 25-39: Very good protection.

- UPF 40-50+: Excellent protection. UPF 50+ is the highest rating, blocking over 98% of UV rays.

A UPF 50 rating means only 1/50th (2%) of the sun's UV radiation can pass through the fabric. This is the benchmark you should aim for in a quality sun-protective umbrella. The rating is determined through standardized laboratory testing (e.g., AS/NZS 4399:2017, AATCC 183, or EN 13758), where a spectrophotometer measures UV transmission through a fabric sample.

What is the Difference Between UVA, UVB, and UPF?

- UVA Rays: Longer wavelengths that penetrate deep into the skin, causing premature aging and long-term damage. They can pass through glass and clouds.

- UVB Rays: Shorter wavelengths that cause sunburn and play a key role in skin cancer development.

- UPF: The rating that measures a fabric's effectiveness against the entire UV spectrum (UVA+UVB). A good UPF test report will show the blocking percentage for both UVA and UVB separately, with UVA blocking typically required to be within 5% of the UPF rating.

Why Can't You Judge Protection by Fabric "Feel" or Color Alone?

This is a critical misconception. A thick, dark cotton canvas may feel protective but can have a surprisingly low UPF if the weave is loose. Conversely, a thin, lightweight polyester with a tight weave and a UV-inhibiting treatment can achieve UPF 50+. While darker colors absorb more UV light than lighter ones (which reflect more onto the skin), and tighter weaves/knits block more than loose ones, these are just contributing factors. The only way to know is through standardized testing. Never accept a supplier's claim of "UV resistant" without a test report.

What Fabric Properties Naturally Enhance UV Blocking?

Before any chemical treatment, the intrinsic properties of the fabric form the first line of defense. You should specify these properties to your fabric mill or umbrella factory to build a strong foundation for UV resistance.

Three Key Intrinsic Factors:

- Fiber Type: Polyester is inherently more UV-resistant than nylon or cotton because its molecular structure absorbs UV radiation well. Acrylic is also good. Natural fibers like cotton or linen, unless very densely woven, tend to have lower natural UPF.

- Fabric Construction (Weave Density): This is often the most important factor. A tighter weave or knit leaves smaller gaps between yarns for UV radiation to pass through. The measurement is often given as thread count per square inch or as cover factor. A high-density polyester pongee (a common umbrella fabric) is a good starting point.

- Color: Darker and more intense colors (black, navy, dark red) absorb UV radiation, preventing it from passing through to the skin. Bright whites and pastels reflect more UV, which can be scattered underneath the fabric. However, a dark color on a loose weave is not enough.

A high-quality umbrella fabric will combine a UV-absorbent fiber (like polyester) with a very high thread count and a darker color.

How Does Thread Count and Fabric Weight (GSM) Relate to UPF?

While not a perfect 1:1 correlation, higher thread count and weight generally support higher UPF.

- Thread Count: For a standard polyester pongee, a count of 190T or higher is a good baseline for sun protection. 210T, 230T are denser and better. Ask your supplier for this specification.

- Fabric Weight (GSM): A heavier fabric (higher GSM) typically indicates more material per square area, which can block more light. However, a lightweight fabric with a very tight weave and treatment can be more effective than a heavy, loose one. Use GSM as one data point among many.

Specify both in your fabric requirements: e.g., "Polyester Pongee, 230T, 110 GSM minimum." This precision is as important as specifying fabric weight for scarves.

Are There Inherently UV-Blocking Fibers?

Some advanced fibers are engineered for UV protection. Microfiber polyester uses ultra-fine filaments to create an exceptionally dense fabric with high UPF without added weight. Certain brands also offer solution-dyed polyester (where color is added to the polymer melt before extrusion), which can have excellent colorfastness and UV stability. While these may cost more, they provide a permanent, non-chemical form of protection that won't wash out.

What Types of UV Treatments and Coatings Are Used?

To achieve a guaranteed high UPF (like 50+), most umbrella fabrics require an added treatment. These treatments work by absorbing or reflecting UV radiation. It's crucial to understand which type your supplier uses, as it affects durability, appearance, and cost.

Primary Types of UV Treatments:

-

UV-Inhibitor Additives in the Yarn: The most common and durable method. UV-absorbing compounds (like benzotriazoles or hindered amine light stabilizers) are mixed into the polymer melt before the polyester yarn is extruded. This protection is built into the fiber itself and lasts the life of the fabric, surviving repeated washing and exposure. This is the preferred method for quality umbrellas.

-

UV-Blocking Coatings (Surface Applications):

- Acrylic or PU Coatings: A layer containing UV blockers is applied to the fabric's surface. While effective initially, these coatings can crack, peel, or wash out over time, especially with folding and exposure to rain.

- Metallic Reflective Coatings: A thin layer of silver or aluminum is applied to the underside of the canopy. This physically reflects UV radiation away before it penetrates the fabric. It's highly effective and gives the canopy a characteristic shiny silver interior. Durability depends on coating quality.

-

Nanoparticle Treatments: Emerging technology where zinc oxide or titanium dioxide nanoparticles are embedded in the fabric. They scatter and absorb UV light effectively and are often more durable than traditional coatings.

How Do "Silver-Coated" Umbrellas Compare to "Blackout" Umbrellas?

Both aim for high protection but through different mechanisms:

- Silver-Coated (Reflective): Has a shiny metallic layer on the inside. Excellent at reflecting both UV and heat, making it cooler underneath. Its UV protection is primarily from reflection. The coating's longevity is key.

- Blackout Umbrellas: Use a triple-layer fabric (often black, white, black) to completely block light. They offer superior UPF (often 50+) and also block visible light, providing a darker shade. They are generally heavier and often achieve high UPF through a combination of density, color, and treatment.

A reputable supplier like Shanghai Fumao Clothing can guide you on the best treatment for your target market and price point.

Do UV Treatments Affect Fabric Breathability or Hand Feel?

Yes, especially coatings. A thick acrylic or PU coating can make the fabric stiffer, less packable, and reduce its ability to breathe (though this is less critical for an umbrella). Solution-dyed yarn with UV-inhibitor additives has virtually no impact on the fabric's hand feel or breathability, as the protection is within the fiber. Always request a fabric swatch to assess the hand feel post-treatment. This is a vital part of the sampling and evaluation process.

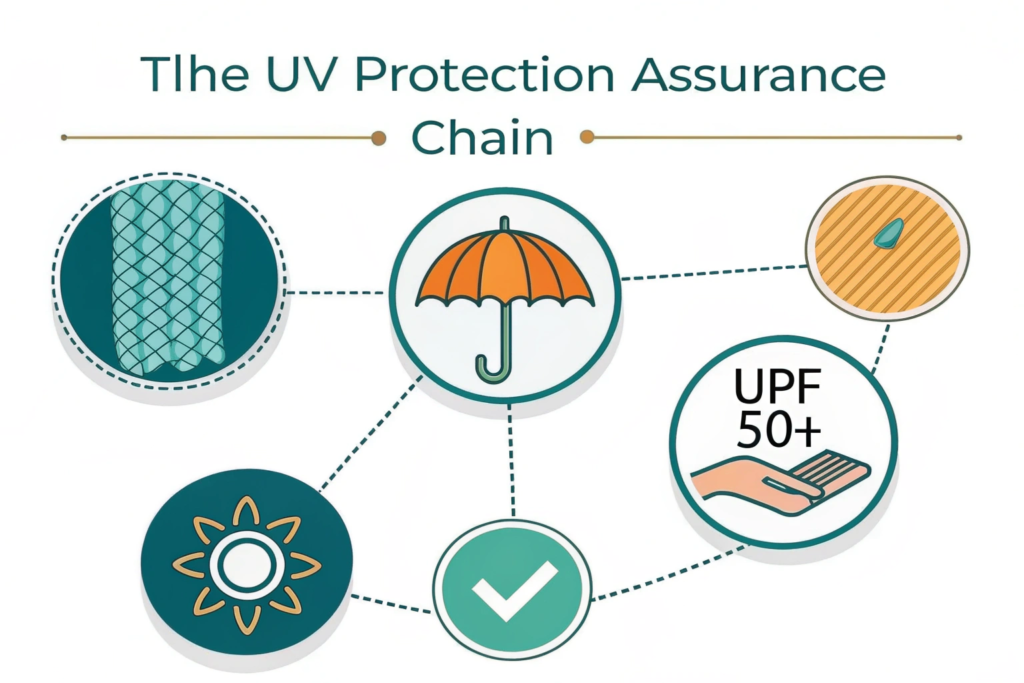

How to Verify UV Resistance Through Testing and Certification?

Trust, but verify. A supplier's word is not enough. You must obtain objective, third-party proof that your specific umbrella fabric meets the claimed UPF standard. This protects your brand and provides a powerful marketing claim.

The Non-Negotiable Steps:

-

Pre-Production: Request a Fabric Test Report. Before you order bulk fabric, require the mill to provide a recent UPF test report from an accredited laboratory (e.g., SGS, Intertek, Bureau Veritas) for the exact fabric specification (composition, weight, color, treatment) you are ordering. The report should state the tested UPF rating and reference the testing standard (e.g., AS/NZS 4399:2017).

-

Production: Conduct Your Own Random Batch Test. For extra security, you can send a swatch from a finished umbrella or the production fabric roll to a lab for independent verification. This confirms the bulk order matches the pre-production sample.

-

Marketing & Labeling: Use the Rating Correctly. Once you have the report, you can confidently label your umbrellas as "UPF 50+" (or the specific rating). In many regions, you can license the use of the ARPANSA (Australian) or Skin Cancer Foundation's Seal of Recommendation if your product passes their specific testing protocols, which adds tremendous consumer credibility.

What Should a Valid UPF Test Report Include?

A legitimate report will have:

- Laboratory Name & Accreditation.

- Test Standard Used (e.g., AS/NZS 4399:2017).

- Sample Description matching your fabric.

- Test Results: Clearly stated UPF Rating (e.g., UPF 50+), UVA Transmittance %, and UVB Transmittance %.

- Classification (e.g., "Excellent Protection").

Keep this report in your Technical File for retailer compliance and consumer inquiries. This level of documentation is as crucial as safety compliance for other accessories.

Can You Perform a Simple "At-Home" Check for UV Protection?

While not a substitute for lab testing, a quick, indicative check can be done with a UV flashlight and a piece of UV-sensitive paper (available in test kits). In a dark room, place the paper under the fabric and shine the UV light on top. If the paper changes color, UV is passing through. If it remains unchanged, the fabric is blocking the UV. This is useful for comparing samples or checking for gross failures, but it does not provide a UPF number.

How to Specify UV Resistance in Your Tech Pack and Supplier Agreement?

To ensure no misunderstandings, embed your UV resistance requirements into your formal sourcing documents. This makes it a contractual obligation, not a hopeful request.

In Your Tech Pack (for the umbrella):

- Fabric Section: "Canopy Fabric: 230T Polyester Pongee, solution-dyed with UV-inhibitor additives, minimum UPF 50 per AS/NZS 4399. Color: Navy Blue (Pantone 19-3920)."

- Testing Requirement: "Supplier must provide a valid third-party UPF test report for the finished fabric prior to bulk production approval."

In Your Purchase Order/Supplier Agreement:

- Include a clause: "Goods must meet the specified UPF 50+ rating. Shipment is contingent upon Buyer's receipt of a passing third-party test report for fabric from the production batch. Non-conforming goods may be rejected at Supplier's expense."

This formal approach aligns incentives and gives you legal recourse, a principle that underpins all reliable manufacturing partnerships.

What Happens to UV Protection When the Fabric Gets Wet?

This is a critical question. Some fabrics lose UPF when wet (cotton can lose up to 50% of its protection). High-quality polyester with solution-dyed UV inhibitors generally retains most of its UPF rating when wet. Some standards, like the Australian/New Zealand standard, require wet testing. When reviewing a test report, check if it specifies "tested in conditioned state" (dry) or if it includes "wet testing." For a rain-and-sun umbrella, wet-state performance is essential. Ask your supplier for data on this.

How Long Does UV Protection Last in an Umbrella?

The longevity depends on the method:

- Solution-Dyed Yarn with Additives: Protection is permanent for the life of the fabric, as it's embedded in the polymer. It won't wash out or degrade significantly with sun exposure.

- Surface Coatings: Protection can degrade over time with abrasion (from folding), washing, and prolonged UV exposure itself. The metallic coating on a silver umbrella can oxidize or wear thin at creases.

When sourcing, prioritize built-in, fiber-level UV protection for a product that maintains its promised performance. This commitment to lasting quality mirrors the ethos behind durable material choices in other accessories.

Conclusion

Ensuring your umbrella fabric is truly UV resistant is a technical process that moves from understanding UPF ratings and intrinsic fabric properties, to specifying and verifying specialized treatments, and finally, to locking in quality through certified testing and clear contractual terms.

By taking this measured, evidence-based approach, you transform a vague marketing claim into a verified product benefit. This builds customer trust, reduces liability, and positions your umbrellas as a reliable tool for health and comfort, not just a barrier against rain.

Ready to source umbrellas with guaranteed, certified UV protection? At Shanghai Fumao Clothing, we work with specialized mills to source high-UPF fabrics, manage the testing process, and ensure your specifications are met from sample to shipment. Contact our Business Director Elaine at elaine@fumaoclothing.com to develop sun-safe umbrellas you can stand behind.