You are deeply invested in the quality and safety of your products. You've meticulously sourced high-quality leather and specified durable, stylish hardware for your new belt collection. But there's a hidden component you're starting to worry about: the glue. You know that adhesives are essential for laminating leather layers, securing linings, and finishing edges. But you've also heard horror stories about toxic glues containing harmful chemicals like toluene or formaldehyde. You're rightly concerned: How do you ensure your supplier isn't using a cheap, toxic adhesive that could pose a risk to their workers, your customers, and ultimately, your brand's reputation?

To ensure your belt supplier uses non-toxic glue, you must move beyond simple verbal assurances and implement a multi-step verification process. This involves explicitly specifying "Low-VOC" or "Zero-VOC" water-based adhesives in your technical pack, demanding Material Safety Data Sheets (MSDS/SDS) for the exact adhesives being used, and contractually requiring compliance with international chemical safety standards like REACH or Prop 65. Trust is not a strategy; documentation and verification are.

I'm the owner of Shanghai Fumao Clothing, and this is an issue we take extremely seriously. The choice of adhesive is a clear indicator of a factory's commitment to quality, safety, and social responsibility. A factory that cuts corners on a hidden component like glue is likely cutting corners elsewhere. For a brand owner, ensuring the use of non-toxic adhesives isn't just about compliance; it's about risk management and building a brand on a foundation of integrity. Let's walk through the professional playbook for controlling this critical, invisible element of your product.

What Are "Toxic" vs. "Non-Toxic" Adhesives in Belt Manufacturing?

Before you can demand the right thing, you need to understand the difference between the good and the bad. In the world of leather goods manufacturing, the primary distinction is between traditional solvent-based adhesives and modern water-based adhesives. This is the core technical knowledge you need.

The primary difference lies in the "carrier" liquid that keeps the adhesive in a usable, fluid state. "Toxic" glues are typically solvent-based, using volatile organic compounds (VOCs) like toluene, benzene, or MEK as the carrier. These VOCs evaporate into the air, creating strong, harmful fumes. "Non-toxic" glues are water-based, using water as the carrier. They have very low or zero VOCs, making them significantly safer for workers, consumers, and the environment.

Let's break down the key characteristics:

- Solvent-Based Adhesives (The "Old Way"):

- How they work: The adhesive solids are dissolved in a volatile solvent. The glue is applied, and the solvent quickly flashes off (evaporates), leaving the sticky adhesive behind. This rapid drying time is why they have been popular for so long in high-speed production.

- The Dangers: The evaporating solvents are the problem. VOCs are linked to a host of health issues, from headaches and respiratory irritation to long-term neurological and organ damage. They are also highly flammable and contribute to air pollution.

- Examples: Barge Cement is a famous (or infamous) example of a powerful, high-VOC solvent-based contact cement used in leatherwork.

- Water-Based Adhesives (The "Modern, Safe Way"):

- How they work: The adhesive solids are suspended in water in an emulsion. The glue is applied, and the water evaporates, leaving the adhesive to form a strong bond. The drying time is generally longer than with solvent-based glues, which can require adjustments to the production process.

- The Benefits: They release primarily water vapor into the air, not harmful chemical fumes. They are non-flammable, have little to no odor, and are much safer for workers to handle. They are the standard in modern, responsible factories.

Why would a factory still use solvent-based glues?

There are two primary reasons: cost and speed. Solvent-based glues are often cheaper to purchase. More importantly, their fast-drying nature can speed up the assembly line, as workers don't have to wait as long for the glue to set before moving to the next step. A factory focused on cutting every possible corner and maximizing output at the expense of safety will be tempted to use them. This is a major red flag about the factory's overall culture.

Are all water-based glues equally good?

No. Even within the water-based category, there are different levels of quality and strength. You need to rely on your manufacturing partner to select a high-quality water-based adhesive that is specifically formulated for leather and provides a strong, durable, and flexible bond that will not become brittle or fail over time. Reputable adhesive manufacturers like 3M or Henkel offer a wide range of high-performance, water-based industrial adhesives.

How Do You Contractually Specify and Verify the Glue?

You cannot leave this to chance or a verbal agreement. You must use the formal documents of the sourcing process—your Tech Pack and your Purchase Order—to create a legally binding requirement. How do you translate your desire for a non-toxic product into an enforceable instruction?

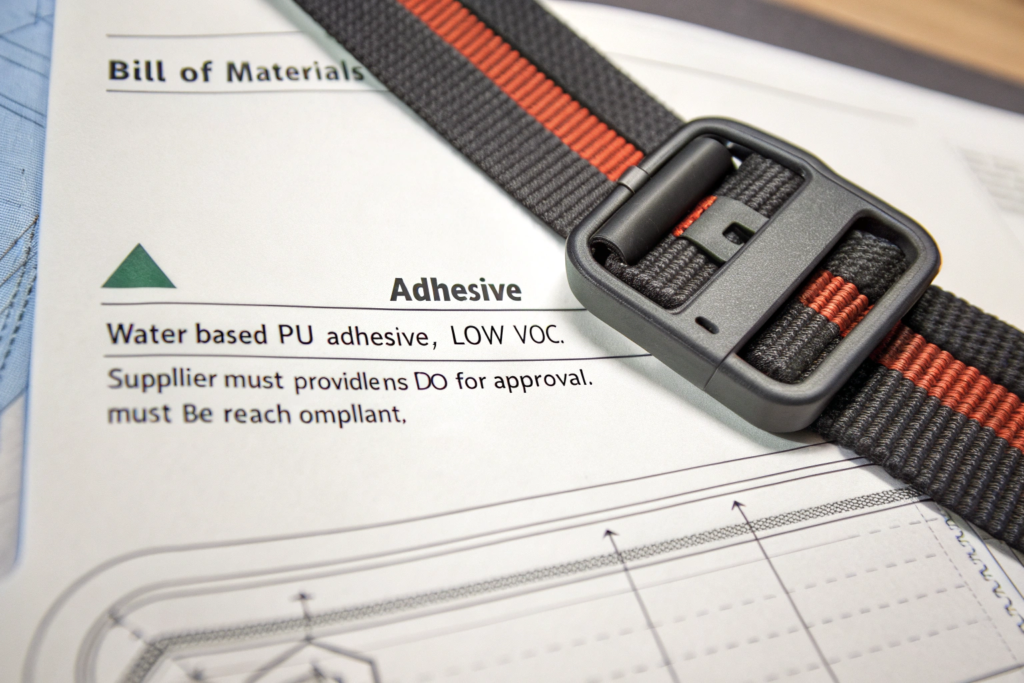

You must explicitly specify the type of adhesive required in the Bill of Materials (BOM) section of your Technical Pack. This specification should be backed by a requirement for the supplier to provide the Material Safety Data Sheet (MSDS or SDS) for the exact product they intend to use. This document is your primary tool for verification. Your requirements should then be referenced in your Purchase Order, making them a contractual obligation.

Here is your three-step documentation and verification process:

- Specify in the Tech Pack: Your Tech Pack is the blueprint for your product. In the Bill of Materials, under the "Adhesive" line item, you should write something like:

- "Adhesive: Water-based polyurethane (PU) contact adhesive. Must be Low-VOC (Volatile Organic Compounds < 50 g/L). Supplier must submit a current Material Safety Data Sheet (SDS) for approval prior to production. All adhesives must be fully compliant with REACH and Prop 65 standards."

- Demand and Review the SDS: The SDS is a standardized document that provides detailed information about the chemical and physical properties of a substance, including its hazards, handling precautions, and composition. When your supplier proposes an adhesive, demand the SDS. You don't need to be a chemist to review it. Look for:

- Section 2 (Hazards): Does it list "flammable liquid," "respiratory irritation," or other major warnings? A water-based adhesive will have very few hazard pictograms.

- Section 3 (Composition): Does it list hazardous solvents like Toluene, Xylene, or Methyl Ethyl Ketone (MEK)? A water-based adhesive will list "Water" as the primary component.

- Section 9 (Physical/Chemical Properties): Look for the VOC content. This should be a low number.

- Reference in the Purchase Order: Your PO is your contract. It should include a clause that says, "All materials and components, including adhesives, must be in accordance with the specifications detailed in Tech Pack [Your Tech Pack ID Number], including all specified compliance standards."

What is an SDS/MSDS?

The Safety Data Sheet (SDS), formerly known as the Material Safety Data Sheet (MSDS), is a document required by international standards like the Globally Harmonized System (GHS). It is the single most important document for verifying the chemical safety of a product. Any reputable factory using industrial chemicals will have these on file and should be able to provide them to you without hesitation. A supplier who is unwilling or unable to provide an SDS for their glue is a massive red flag.

What are REACH and Prop 65?

These are crucial chemical regulation standards.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is a European Union regulation. It requires companies to identify and manage the risks linked to the substances they manufacture and market in the EU. It restricts the use of many hazardous chemicals. Demanding REACH compliance is a global best practice.

- California Proposition 65 is a California state law that requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. The list of chemicals is extensive.

Even if you don't sell in the EU or California, demanding compliance with these strict standards is the easiest way to ensure you are meeting a high global standard for chemical safety.

How Can You Physically Test and Monitor for Compliance?

Documentation is your first line of defense, but how do you ensure the factory is actually using the approved adhesive on the production line day after day? What if they show you the SDS for a safe glue but then use a cheaper, toxic one to save money? This is where physical monitoring and testing come in.

While documentation is key, you can add layers of physical verification through factory audits and third-party laboratory testing. During a factory visit or a third-party inspection, you can visually inspect the adhesive being used on the production line and check if the container matches the approved SDS. For the highest level of assurance, you can have an inspector collect a sample of the adhesive during production and send it to a lab for chemical analysis.

Here are your options for physical verification:

- Visual Inspection During Factory Audits: If you or your agent visit the factory, make a point of walking the belt production line. Ask to see the glue that is being used. Look at the drums or containers. Do they have a manufacturer's label? Does the product name match the SDS you approved? Take a photo for your records. Look for signs of high-VOC use, like strong chemical smells or workers needing heavy-duty respirators.

- Third-Party Inspections: You can hire a professional third-party inspection company (like QIMA, SGS, or Intertek) to perform a "During Production" (DUPRO) inspection. You can specifically instruct the inspector to check the adhesive being used and take photos of the containers. This is a very cost-effective way to have eyes on the ground.

- Laboratory Testing: This is the ultimate, most definitive method. You can have the inspector collect a sample of the wet glue from the production line and send it to an accredited laboratory. The lab can perform a chemical analysis to identify its composition and test for the presence of specific restricted substances (like benzene or toluene). You can also have them test a finished belt for any residual VOCs. This costs more but provides undeniable scientific proof of compliance or non-compliance.

How much does third-party lab testing cost?

The cost can vary widely depending on the number of chemicals you are testing for, but you can often get a basic screen for common restricted substances for a few hundred dollars. When you consider the potential cost of a product recall or a lawsuit due to a safety violation, the cost of a verification test is a very reasonable insurance policy.

Can I smell the difference?

Often, yes. Solvent-based adhesives have a very strong, sharp, and distinct chemical smell that is often described as being similar to model airplane glue or harsh paint thinner. Water-based adhesives have a very low odor, often smelling faintly like a mild household glue (like Elmer's glue). If you receive a belt sample and it has a powerful, lingering chemical smell, it's a strong indicator that a solvent-based glue was used.

What Are the Hallmarks of a Responsible Supplier?

Ultimately, your best strategy is to partner with a supplier who is already committed to safety and responsibility. A good factory doesn't need to be forced into using non-toxic materials; they do it by default because it's the right thing to do for their workers and their clients. What are the signs that a supplier "gets it" and can be trusted on issues like this?

A responsible supplier demonstrates their commitment to safety through transparency, documentation, and a clean, safe working environment. They will proactively offer you the SDS for their materials, welcome factory inspections, and often hold certifications like ISO 9001 (for quality management) or ISO 14001 (for environmental management). Their factory will be well-ventilated, and their workers will be equipped with appropriate, but not excessive, personal protective equipment (PPE).

Look for these positive indicators:

- Transparency and Proactiveness: When you ask for the SDS, they don't hesitate. They send it immediately and understand why you are asking. They might even mention their use of water-based glues in their initial marketing materials.

- Existing Certifications: While not a direct guarantee, certifications like ISO 14001 or a positive social compliance audit (like BSCI or Sedex) show that the factory is used to being audited and has systems in place for managing its environmental and social impact.

- A Clean and Well-Ventilated Factory: A factory that invests in good ventilation and a clean working environment is a factory that cares about its workers' health. This is one of the most telling visual cues during a factory visit.

- Appropriate PPE Usage: In a factory using safe, water-based glues, you should not see workers needing heavy-duty, full-face respirators for belt assembly. The absence of such extreme PPE can actually be a positive sign that the air quality is good.

Is a higher price a good indicator?

Often, yes. Using high-quality, water-based adhesives and investing in proper ventilation costs more than using cheap, toxic materials in a poorly-ventilated workshop. A factory that gives you a price that seems "too good to be true" is almost certainly cutting corners, and a hidden component like glue is one of the first places they will do it.

How can a partner like AceAccessory help?

As a responsible manufacturer, we have already done this work. We have standing relationships with reputable adhesive suppliers, we maintain a full library of SDS for all our chemical inputs, and our factory is designed for safety and compliance. When you work with a partner like Shanghai Fumao Clothing, you are leveraging our existing system of compliance and verification. We can provide you with all the necessary documentation to give you, and your customers, complete peace of mind.

Conclusion

The adhesive that holds your belt together also holds a piece of your brand's reputation. Ensuring your supplier uses non-toxic glue is a critical step in building a responsible, sustainable, and trustworthy brand. This process cannot be based on hope or a handshake. It requires a systematic approach: explicitly specifying safe, water-based adhesives in your technical documents, demanding and verifying the Material Safety Data Sheets, and contractually requiring compliance with strict international safety standards. By embedding these verification steps into your sourcing process, you protect your customers, you protect your brand, and you send a clear message to the market that you are a brand that cares about every detail, seen and unseen.

At Shanghai Fumao Clothing, we believe that quality is not just about the materials you can see, but also about the integrity of the components you can't. We have built our operations on a foundation of safety, transparency, and compliance. If you are looking for a manufacturing partner who can provide you with the documentation and the peace of mind that your products are made to the highest standards of safety and quality, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com.