Your focus is often on the exciting parts of the business: designing new products, marketing, and sales. But behind the scenes, a hidden operational challenge can quietly sabotage your success: warehouse organization. You're looking at your current storage space—a chaotic mix of un-labeled boxes, overflowing bins, and confusing piles of inventory. You know this is a problem. It's leading to slow order fulfillment, lost inventory, and frustrated staff. You're ready to fix it, but you're facing a daunting task. Where do you even begin? How do you transform this chaos into a highly efficient system specifically designed for the unique challenges of storing small, varied fashion accessories?

To effectively organize a warehouse for accessory storage, you must implement a systematic, location-based inventory management system. This involves categorizing your diverse inventory, selecting the right high-density storage solutions (like bins and dividers), creating a logical warehouse layout with clearly defined zones, and leveraging a barcode-based system to track the precise location of every single item. The goal is to create a "smart" warehouse where anyone can find anything in seconds, not minutes.

I'm the owner of Shanghai Fumao Clothing, and while we are a manufacturer, we operate a large and complex warehouse to manage raw materials and finished goods. I can tell you from firsthand experience that warehouse efficiency is not an expense; it's a profit center. Every minute saved finding a product, every error avoided in shipping, and every piece of inventory not lost, drops directly to your bottom line. A well-organized warehouse is a powerful competitive advantage. Let's break down the professional methodology for creating a world-class accessory storage system.

How Do You Implement a Location-Based Inventory System?

This is the single most important concept you need to grasp. The root of most warehouse chaos is a lack of a formal location system. People put items wherever they see an empty space, and then the location exists only in their memory. This is a recipe for disaster. You need to create a system where the system knows where everything is, not a person.

A location-based inventory system is a method where every single storage location in your warehouse—every aisle, every shelving unit, every shelf, and every bin—is given a unique, permanent address or "license plate." Products are not stored by type, but are placed into an available location, and that location's address is then electronically associated with the product's SKU in your inventory management software. This decouples the product from a fixed location, creating immense flexibility and accuracy.

Here's how to set up the addressing system:

- Create a Naming Convention: A simple and common convention is Aisle - Bay - Shelf - Bin.

- Aisle: Assign a letter to each aisle (A, B, C...).

- Bay: Number each vertical section of shelving within an aisle (01, 02, 03...).

- Shelf: Assign a letter to each shelf level, starting from the bottom up (A for the bottom shelf, B for the next, etc.).

- Bin: Number each bin or position on a shelf (01, 02...).

- Result: A typical location address would look like A-02-B-04. This is the unique address for Bin 4 on Shelf B in Bay 2 of Aisle A.

- Label Everything: Physically print and apply a durable barcode label with the human-readable address to every single storage location. This is a time-consuming but absolutely critical task.

- Integrate with Software: This system requires inventory management software (from a simple spreadsheet for very small operations to a dedicated Warehouse Management System - WMS). When you "receive" a new shipment of headbands (SKU 789), you place them in an empty bin, scan the headband's barcode, and then scan the bin's location barcode (e.g., C-05-A-01). Your system now knows that SKU 789 is at that address.

When an order comes in for SKU 789, the system doesn't tell the picker to "go find the headbands." It tells them to "go to location C-05-A-01 and pick two units." This is the difference between chaos and control.

What is the benefit of this "chaotic storage" system?

The method of placing items in any available open location is often called "chaotic storage," but it's actually the opposite of chaos. Its benefits are immense:

- Space Optimization: You are no longer reserving huge areas for a product that might be out of stock. You use every available space, which can dramatically increase your warehouse's storage density.

- Accuracy: The system relies on scanning, which is far more accurate than human memory. This drastically reduces picking errors.

- Flexibility: As your product mix changes, you don't have to re-organize the entire warehouse. You simply find new empty locations for new products.

- Ease of Training: A new employee doesn't need to learn where everything is. They just need to learn how to read a location address and use a scanner. They can be productive on their first day.

What kind of software do I need?

For a small but growing business, many modern e-commerce platforms like Shopify have built-in inventory management features that support locations. As you grow, you would graduate to a dedicated Warehouse Management System (WMS) that offers more advanced features like optimized picking paths and cycle counting.

How Do You Choose the Right Storage Solutions for Accessories?

Fashion accessories are a unique storage challenge. You're not storing large, uniform pallets. You're storing thousands of small, individual, and highly varied items: scarves, belts, hats, hair clips, earrings, etc. Using a one-size-fits-all cardboard box is incredibly inefficient and will lead to damaged products and wasted space.

You must select high-density storage solutions that are appropriately sized for your specific products. For small accessories, the best solution is typically a system of modular, open-fronted plastic bins placed on industrial shelving. Using clear bins or bins with internal dividers allows you to maximize the use of shelf space while keeping individual SKUs separate, visible, and easily accessible.

Here's how to choose the right solutions:

- Shelving: Start with standard, adjustable industrial steel shelving. It's durable, cost-effective, and flexible.

- Bins, Bins, Bins: Bins are the heart of your system.

- Small Parts Bins: For items like hair clips, earrings, or patches, use small, stackable, or hanging plastic bins. Using clear bins allows for quick visual identification.

- Shelf Bins: For items like scarves, beanies, or gloves, use larger, open-fronted plastic bins that fit neatly onto your shelves. This allows pickers to easily reach in and grab an item without having to pull down a heavy box.

- Dividers: For products that have many color or size variations (like a single style of headband that comes in 10 colors), use bins with adjustable internal dividers. This allows you to store all variations of a single SKU in one bin, each in its own compartment, which is incredibly efficient.

- Specialty Storage:

- Belts: Belts can be coiled and placed in bins, but a more space-efficient method can be a specialized rack that allows them to be hung.

- Baseball Caps: Caps should be stored in a way that doesn't crush the crown. Stacking them loosely in a deep bin is a common and effective method.

Should I use cardboard or plastic bins?

While cardboard is cheaper upfront, plastic bins are a far better long-term investment. They are significantly more durable, they don't degrade with humidity, they are easier to clean, and they won't collapse if they get wet. Many are also designed to stack and interlock, creating a more stable and organized system. The upfront cost is higher, but the longevity and performance are worth it.

What is the "golden zone"?

The "golden zone" or "strike zone" refers to the shelving area that is between a picker's shoulders and knees. This is the most ergonomic and fastest area to pick from. Your inventory management system should be programmed to direct you to store your fastest-moving, most popular products (your "A-items") in these prime locations. Slower-moving items can be stored on the higher or lower shelves. This simple optimization can dramatically increase your picking speed.

How Do You Design an Efficient Warehouse Layout?

The physical layout of your warehouse—the arrangement of your aisles, zones, and workstations—has a massive impact on your team's efficiency. A poor layout creates bottlenecks, long travel times, and a chaotic work environment. A good layout creates a smooth, logical, and fast-flowing production line.

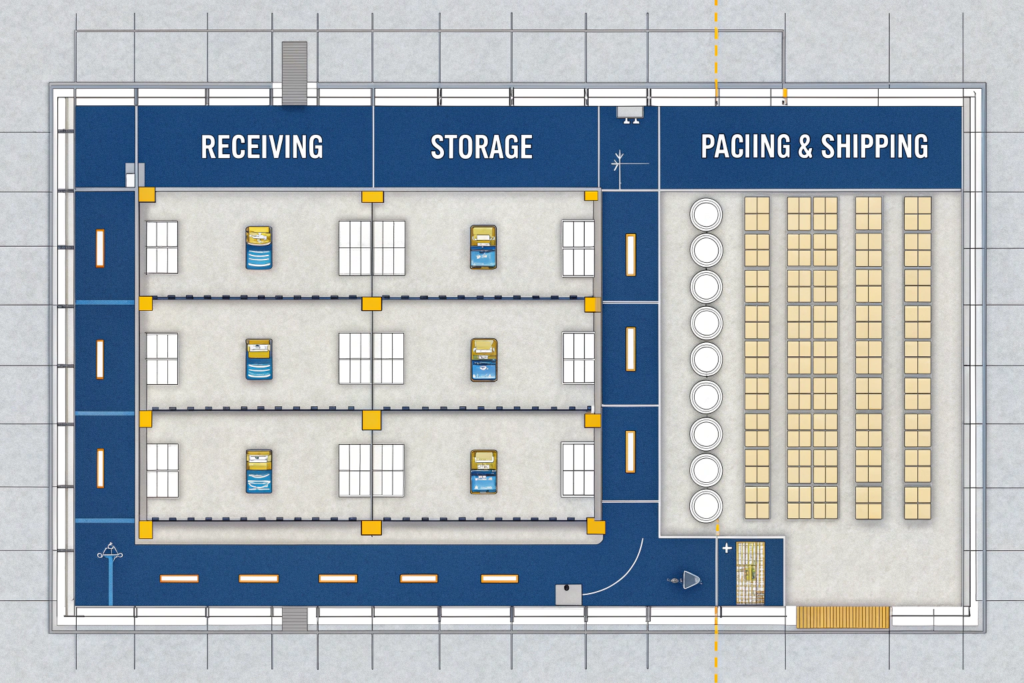

An efficient warehouse layout should be designed around a clear, one-way process flow, typically in a "U" shape. This involves creating distinct, dedicated zones for each major function—Receiving, Storage, Picking/Packing, and Shipping—and arranging them in a logical sequence to minimize travel distance and prevent congestion. The aisles should be wide enough for safe movement but not so wide that they waste space.

Let's break down the key zones:

- Receiving Zone: This is where new inventory arrives from your suppliers (like Shanghai Fumao Clothing). It needs ample space for unpacking boxes, inspecting goods for quality, and applying barcode labels to each product. This zone should be kept separate from your main storage to prevent un-processed inventory from getting mixed in.

- Storage Zone: This is the main area with all your shelving and bins. As discussed, it should be organized with a clear location-based labeling system.

- Picking & Packing Zone: This is where the magic happens. After an item is "picked" from the storage zone, it comes to a dedicated packing station. Each station should be fully equipped with everything a packer needs: boxes of various sizes, packing tape, void fill (like paper or air pillows), a shipping label printer, and a computer terminal. A well-designed station prevents the packer from having to walk around searching for supplies.

- Shipping Zone: This is a staging area where packed and labeled boxes are sorted by carrier (e.g., UPS, FedEx, USPS) and await pickup.

This zonal approach creates a clear production line and prevents, for example, a receiving worker from getting in the way of a shipping worker.

How wide should the aisles be?

Aisle width is a trade-off between storage space and ease of movement. For a small warehouse where staff are picking by hand or with small carts, an aisle width of 3 to 4 feet is often sufficient. If you are using larger rolling carts or pallet jacks, you will need wider aisles. The key is to make them wide enough for two people or carts to pass each other safely without being excessively wide and wasting valuable floor space.

What about safety considerations?

Safety is paramount. Your layout must include clear, unobstructed pathways. All shelving must be securely anchored to the floor or wall to prevent tipping. You need adequate lighting throughout the warehouse, especially in the aisles. Fire extinguishers and first-aid kits should be clearly marked and easily accessible, in compliance with local safety regulations like those from OSHA.

How Do You Maintain and Optimize the System?

Your beautiful, organized warehouse is not a one-time project; it's a living system that requires constant maintenance and optimization to remain effective. If you "set it and forget it," chaos will slowly creep back in. You need to implement processes that ensure the system's accuracy and efficiency over the long term.

To maintain your organized warehouse, you must implement a regular "cycle counting" program to ensure inventory accuracy and continuously analyze your sales data to optimize product placement. Cycle counting involves counting small, specific sections of your inventory each day, rather than doing a massive, disruptive annual stock-take. This proactive process catches errors early and keeps your system's data clean and reliable.

Here are the key maintenance processes:

- Cycle Counting: Instead of shutting down your entire warehouse for a week once a year to count everything, you count a few specific locations every single day. Your WMS can even generate a daily list of locations to count. For example, on Monday you count locations A-01-A through A-01-C. On Tuesday, you count A-01-D through A-01-F. This process is less disruptive, more accurate, and allows you to quickly identify and fix the root causes of inventory discrepancies (e.g., a specific picker who is making errors).

- Regular Re-slotting: Your sales patterns will change over time. A product that was a slow-mover last year might be a best-seller this year. Every quarter, you should analyze your sales data and "re-slot" your warehouse. This means moving your new, fast-moving "A-items" into the "golden zone" and moving the newly slow-moving items to less accessible shelves. This ensures your layout is always optimized for your current sales reality.

- A Culture of Cleanliness: Implement a "clean as you go" policy. Staff should be trained to break down empty boxes immediately, put tools back in their designated places, and keep the aisles clear. A clean warehouse is a safe and efficient warehouse.

How does cycle counting work with a WMS?

A good WMS makes cycle counting easy. It will generate a count task (e.g., "Count location B-03-C-05"). The worker goes to the location, scans the location barcode, and then counts the physical units. They enter the count into their scanner. The system then compares the physical count to the quantity it thought was there. If there is a mismatch, it will flag it for a manager to investigate and correct.

How do I get my team to follow the new system?

Training and buy-in are essential. You must clearly explain the "why" behind the new system—how it will make their jobs easier, less frustrating, and more efficient. Provide thorough training on how to use the scanners and follow the processes. It's also important to lead by example. If the managers don't follow the system, the staff won't either. Consistency from everyone is key to breaking old habits and building a new culture of organization.

Conclusion

Organizing your warehouse is one of the highest-leverage investments you can make in your business. By transforming chaos into a controlled, systematic environment, you will not only reduce errors and increase efficiency but also create a calmer, less stressful workplace for your team. The journey begins with the fundamental shift to a location-based inventory system, supported by the right high-density storage solutions and a logical, process-driven layout. But it is sustained through a disciplined commitment to continuous maintenance, cycle counting, and optimization. This systematic approach will turn your warehouse from a costly operational bottleneck into a powerful strategic asset that can fuel your brand's growth for years to come.

At Shanghai Fumao Clothing, our manufacturing efficiency is built on these same principles of warehouse organization. We understand how to manage a high volume of diverse SKUs with precision and speed. If you are looking for a partner who not only delivers a quality product but also understands the operational discipline required to support a growing brand, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com.