As a brand manager for hair accessories, you know that a hair band is not just a simple loop of fabric. Its entire purpose hinges on one critical property: elasticity. A hair band that is too loose will fail to hold hair securely. One that is too tight will cause headaches and hair breakage. And one that loses its stretch after a few uses is a complete failure that leads to customer complaints and damages your brand's reputation for quality. You need to be sure your products perform perfectly, but how do you actually measure and guarantee something as seemingly simple as "stretchiness"?

To properly test the elasticity of hair bands, you must move beyond a simple hand-stretch and implement a systematic, multi-stage testing protocol. This involves using specialized equipment for quantifiable lab tests (like extension and recovery tests), performing real-world user trials to assess functional performance, and conducting longevity tests to simulate the product's lifespan. This three-pronged approach is the only way to guarantee consistent quality and performance.

I'm the owner of Shanghai Fumao Clothing, and for a product as fundamental as a hair band, quality control is everything. We've manufactured millions of them, and I can tell you that the most successful brands are the ones who are obsessed with the technical performance of their elastic. They don't just hope it's good; they test it, quantify it, and specify it. Let's walk through the professional methods we use to ensure every hair band we produce meets the highest standards of performance and durability.

What Are the Key Metrics of Elasticity?

Before you can test elasticity, you need to understand what you're actually measuring. "Stretchiness" is a vague term. In a manufacturing context, we need to break it down into specific, measurable properties. You're worried that if you can't define what "good elasticity" means, you'll have no way to enforce it with your supplier.

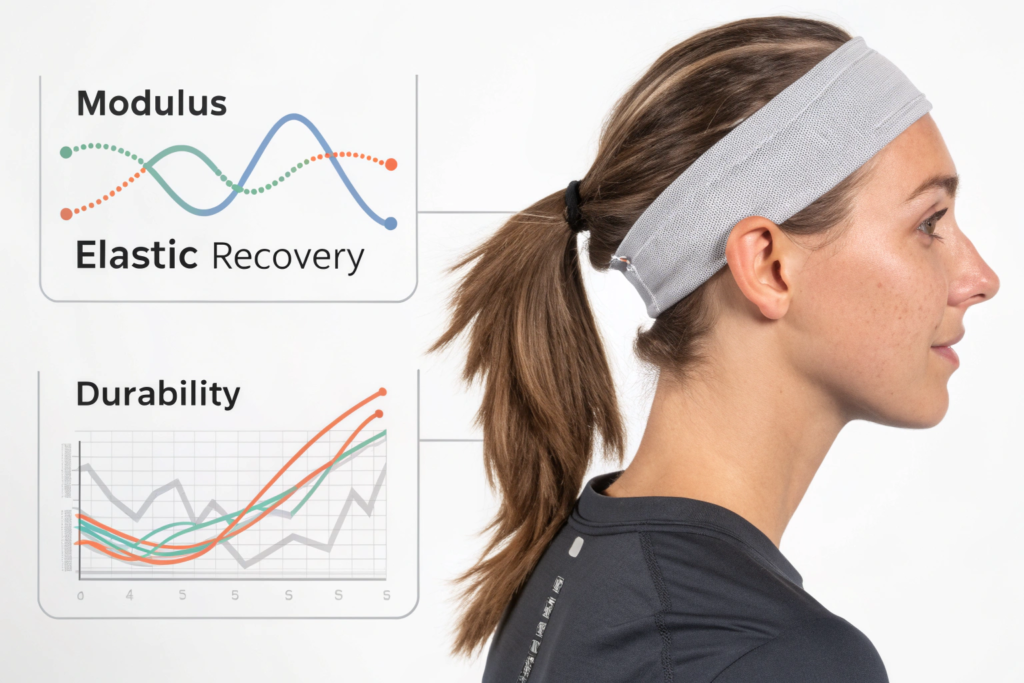

The performance of a hair band is defined by three key metrics: Modulus (the force required to stretch it), Elastic Recovery (its ability to return to its original size), and Durability (how well it maintains these properties over time). A great hair band has a balanced profile across all three.

Think of these three metrics as the pillars of performance:

- Modulus (Stretch Force): This is how much effort it takes to stretch the hair band. A low modulus means it's easy to stretch (good for not breaking hair), but too low and it won't hold hair securely. A high modulus means it's very firm and holds tight, but too high and it's uncomfortable and can cause headaches. The goal is a "just right" Goldilocks zone.

- Elastic Recovery (The "Snap Back"): This measures how completely the hair band returns to its original shape after being stretched. Poor recovery is what causes a hair band to become loose and baggy after just a few uses. A good hair band should have high elastic recovery, close to 100%.

- Durability (Longevity): This measures how many times a hair band can be stretched and relaxed before its modulus and recovery properties begin to degrade significantly or it breaks. This is the test of its lifespan. Understanding these terms allows you to have a much more technical and precise conversation with your manufacturer.

What materials provide the best balance?

The "engine" of a hair band is the elastomeric core. High-quality options include natural rubber latex or, more commonly for allergy reasons, synthetic materials like spandex (Lycra/elastane). The quality and thickness of this core are the primary determinants of the hair band's performance. The outer sheath (often cotton, nylon, or polyester) protects the core and provides the look and feel.

Is there an industry standard for these metrics?

While there isn't a single universal standard for hair bands specifically, the testing methods are based on established principles from the textile and polymer industries, often adapting standards from organizations like ASTM International that deal with testing elastic fabrics. A good manufacturer will have their own internal benchmarks based on years of experience.

How Are Lab Tests Performed?

You've asked your supplier if their hair bands are "good," and they've assured you they are. But this is a subjective claim. You need objective, quantifiable data to compare different samples and to set a clear quality standard for your bulk production. You're worried that without this data, quality will be inconsistent from one order to the next.

Professional manufacturers use a machine called a tensile tester (or force gauge) to perform quantifiable laboratory tests. This equipment precisely measures the force required to stretch a hair band to a specific length (modulus) and its ability to return to its original size after the force is released (recovery).

This is how you move from subjective feelings to objective facts. At Shanghai Fumao Clothing, our QC lab uses these machines to create a performance "fingerprint" for every type of hair band we make. Here's how the tests work:

- Extension/Modulus Test: The hair band is clamped into the machine. The machine then pulls it to a pre-determined length (e.g., 15 cm, which might simulate stretching it to go around a ponytail) and records the exact force (in Newtons or pounds-force) required to reach that length. This gives you a hard number for the "stretch force."

- Elastic Recovery Test: After the extension test, the machine holds the hair band at its stretched length for a set period (e.g., 1 minute) and then releases it. After another set period (e.g., 1 minute) to allow it to rest, the machine measures its new, final length. The recovery is calculated as a percentage. For example, if a 5 cm hair band is stretched and returns to a final length of 5.1 cm, it has not fully recovered. A high-quality band should have 95%+ recovery.

How do I use this data?

This data allows you to create a clear specification, a precise roadmap that transforms vague ideas into tangible requirements. You can tell your supplier with unwavering confidence: 'The hair band must have a stretch force between 5N and 7N at 15cm extension, and an elastic recovery of at least 95%.' Imagine the scene—your voice steady, deliberate, as you lay out these numbers, each one a cornerstone of quality. The supplier nods, pen in hand, ready to translate these words into action. This is no mere suggestion; it is a clear, enforceable standard, a contract written in the language of precision that leaves no room for ambiguity, no space for guesswork or half-measures.

What is a cycle test?

For durability, the same machine can be programmed to perform a cycle test. It will stretch and relax the hair band repeatedly—hundreds or even thousands of times—and then re-measure the modulus and recovery. This test simulates the product's lifespan and shows how quickly it will degrade with use. You can specify, for example, that "after 500 cycles, the stretch force must not decrease by more than 20%."

How Do I Conduct Effective User Trials?

Lab data is essential, but it doesn't tell the whole story. A hair band can have perfect numbers on a machine but feel terrible in the hair. It might snag, pull, or simply not work well with certain hair types. You're worried that by relying only on lab data, you might miss crucial functional flaws that will only be discovered by your end customers.

You must supplement lab data with structured, real-world user trials. This involves providing samples to a panel of testers with diverse hair types (thick, thin, curly, straight) and asking them to use the product for a set period and provide specific feedback on comfort, hold, and ease of use.

This is your reality check. The feedback from these trials is just as valuable as the data from the lab. Your test panel should be representative of your target customer. Provide them with a simple survey to fill out after a trial period (e.g., one week). The questions should be specific:

- Application: Was it easy to twist and apply? How many twists did it take to feel secure?

- Hold: Did the hair band hold your ponytail securely during normal activity? During exercise? Did it slip or loosen throughout the day?

- Comfort: Was it comfortable to wear on your wrist? Did it cause a headache when worn in your hair all day?

- Removal: Did it snag, pull, or break hair upon removal?

- Appearance: How did the hair band look after one week of use? Was it baggy, frayed, or discolored?

The insights from these qualitative tests can reveal issues that lab tests can't, such as a fabric sheath that snags fine hair, even if the elastic core is perfect.

How many people should I test with?

You don't need a massive group, a throng of voices lost in the chaos of too many opinions. Instead, imagine a carefully curated panel of 10 to 15 individuals, each bringing a unique tapestry of hair types to the table—coily curls that bounce like liquid silk, straight strands smooth as polished glass, wavy locks that cascade with a gentle, undulating rhythm, and everything in between. This intimate circle becomes a microcosm of diversity, where every perspective is sharp, every observation rooted in lived experience. Here, feedback isn't just words on a page; it's the rustle of a friend running a hand through their textured hair and saying, 'This product makes my curls pop without frizz,' or the quiet confidence of someone with fine, straight hair sharing, 'I need something that adds volume without weighing me down.'

How do I compare different samples?

If you are comparing a sample from Supplier A and Supplier B, give both to your test panel—a carefully curated group of discerning users whose palates or experiences will serve as the ultimate judge. Opt for a 'blind test,' where the identities of the samples remain shrouded in mystery, even to the participants themselves; this eliminates bias, ensuring that judgments are rooted purely in performance, not preconceived notions. Present the samples side by side, perhaps on a clean, uncluttered table under soft, neutral lighting that won't skew perceptions. Let the testers engage with them—taste the subtle nuances of flavor, the texture that lingers on the tongue, the aroma that wafts gently into the air.

How Can I Test for Long-Term Durability?

A hair band might perform perfectly for the first week, but what about the first month? Customers expect accessories to last. You're worried that your product will fail prematurely, leading to a perception that your brand sells low-quality, disposable items. You need a way to predict how your hair bands will hold up over time.

To test for long-term durability, you must perform accelerated aging and wear tests. This involves subjecting the hair bands to conditions that simulate months of use in a compressed timeframe, such as repeated wash cycles and prolonged stretching.

These tests are designed to predict failure points.

- The Wash Test: Wash and dry the hair bands repeatedly (e.g., 20-30 cycles). This tests the colorfastness of the fabric and whether the elastic core can withstand the heat and agitation of laundering. Does the color fade? Does the elastic become brittle or lose its stretch?

- The Creep Test: Stretch the hair band around a fixed object (like a jar or a custom-sized cylinder) that holds it at a constant, medium stretch. Leave it there for an extended period (e.g., 48 hours). After removing it, let it rest for an hour and then measure its recovery. This test is excellent for revealing "creep"—the tendency of a material to deform permanently under a constant load.

- The Abrasion Test: Rub the fabric surface of the hair band with an abradant cloth to see how quickly it pills or frays. This simulates the friction it will experience against hair and when worn on the wrist.

These longevity tests, combined with the lab-based cycle tests, give you a comprehensive picture of how your product will perform over its entire lifecycle.

What about chemical resistance?

For a hair accessory, it's also wise to test for resistance to common chemicals it might encounter. This includes spraying the hair band with hairspray, or exposing it to salt water and chlorinated water (to simulate swimming) to see if it affects the color or the elastic's integrity.

How Does Temperature Change Affect the Long-Term Elasticity of Hair Bands?

The delicate dance of elasticity in hair bands, those unassuming accessories that cradle our tresses, is a silent symphony of molecular interactions, and temperature—both the gentle warmth of a sunlit day and the harsh chill of a winter breeze—plays a pivotal role in conducting this melody over time. Imagine a hair band, fresh from its packaging, its elastic material supple and eager, like a spring coiled tight yet ready to unfurl with a soft stretch.

In the embrace of moderate temperatures, say the cozy 70°F (21°C) of a well-lit bathroom, its fibers dance in harmony: the polymer chains within the elastic, perhaps made of spandex or latex, slide past one another with ease, allowing the band to stretch smoothly when placed around a head and snap back into place with a satisfying snap, keeping hair secure without pulling.

Conclusion

Testing the elasticity of a hair band is a science. By moving beyond a simple hand-stretch and adopting a professional, three-pronged approach—combining quantifiable lab data, real-world user feedback, and long-term durability trials—you can develop a product that truly performs. This rigorous process allows you to define a clear, enforceable quality standard, ensuring that every hair band you sell provides the perfect balance of a secure hold, all-day comfort, and lasting durability. It's this commitment to technical excellence that separates market-leading brands from the rest.

At Shanghai Fumao Clothing, this level of rigorous testing is standard procedure. We believe that data and real-world feedback are the keys to creating superior products. We have the equipment, the expertise, and the quality-obsessed mindset to be your trusted manufacturing partner. If you are ready to create a line of hair accessories built on a foundation of proven performance, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com.