You're watching the first snowflakes of winter fall, and a sense of panic begins to set in. Your customers are starting to search for cozy hats, scarves, and gloves, but your inventory is thin. You scramble to contact your supplier, only to be told that production lead times are at their peak and shipping lanes are congested with holiday traffic. You're facing the nightmare scenario: missing the most profitable sales window of the year because you started too late.

The best time to order winter accessories is between late winter and early spring, ideally from February to April. This allows for a 6-to-9-month lead time, which is essential for a stress-free process that includes thoughtful design, proper material sourcing, rigorous quality control, and cost-effective sea freight, ensuring your products are on your shelves by September, ready for the first chill.

I'm the owner of Shanghai Fumao Clothing, and I've seen this cycle play out year after year. The most successful US and European brands we partner with operate on a "reverse season" calendar. They aren't thinking about winter in the winter; they are planning for it. Ordering early isn't just about avoiding delays; it's a strategic decision that gives you a massive competitive advantage in quality, cost, and preparedness. Let's break down the timeline and show you why this counter-intuitive timing is the secret to a successful winter season.

Why Is a 6-9 Month Lead Time Essential?

You're a growing brand, and managing cash flow is a constant balancing act. The idea of placing a large order for winter goods in March, paying a deposit for products you won't sell for another six months, feels risky and counter-intuitive. You're tempted to wait until summer, when the need feels more immediate and cash might be more readily available.

A 6-to-9-month lead time is essential because it transforms your production process from a rushed, high-risk gamble into a controlled, strategic operation. This buffer period is not "wasted time"; it is actively used for critical stages like material sourcing, sample refinement, mass production, and, most importantly, economical sea freight, all of which are compromised in a rushed timeline.

Think of all the steps that happen between your idea and a product landing in your warehouse. Each one takes time. Rushing this process inevitably leads to compromises. You might have to accept a lower-quality yarn because the ideal material isn't in stock. You might skip a second round of samples to save time, only to discover a flaw in the final production. You might be forced to pay for expensive air freight to avoid missing the season entirely, wiping out your profit margin. As manufacturing experts, we see that the brands who build in this buffer are the ones who consistently deliver the highest quality products at the best price.

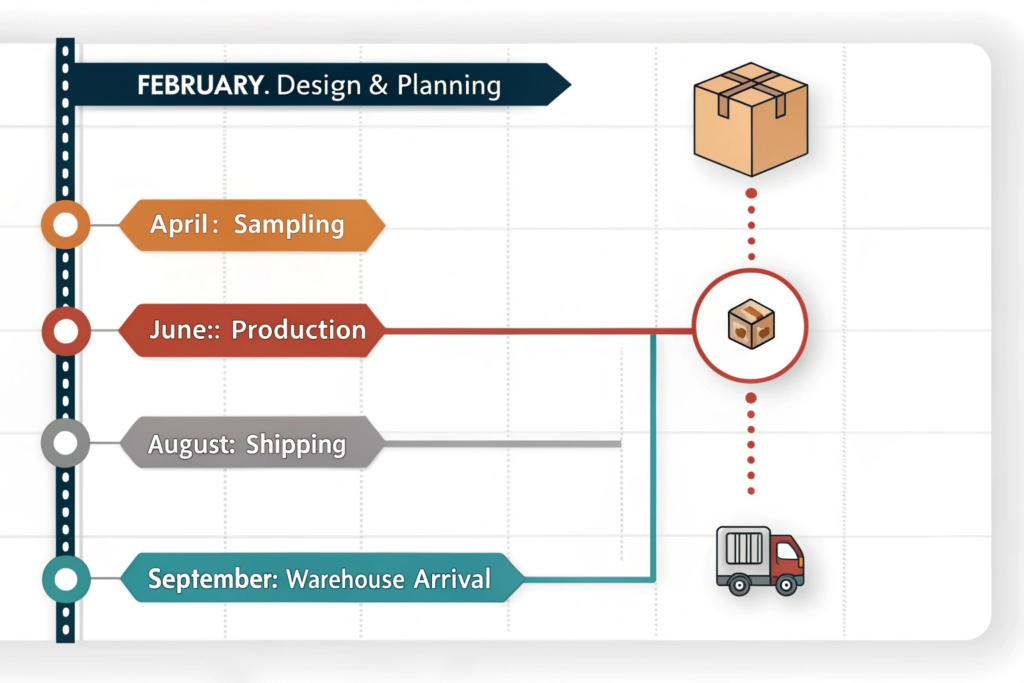

What does a typical 9-month timeline look like?

Here is a sample professional production calendar:

- February-March (9-8 months out): Finalize designs, trend research, initial supplier conversations.

- April (7 months out): Approve materials, order and receive first prototypes (samples).

- May (6 months out): Test samples, provide feedback, approve final pre-production sample.

- June-July (5-4 months out): Mass production begins.

- August (3 months out): Production finishes, goods pass final inspection and are booked for shipping.

- September (2 months out): Goods are on the water (sea freight).

- October (1 month out): Goods arrive, clear customs, and are delivered to your warehouse, ready for distribution.

What are the biggest risks of a shorter timeline?

A timeline under 6 months forces you into a series of costly trade-offs:

- Material Compromises: You're limited to in-stock materials, not the best materials.

- Reduced Quality Control: You may have to skip crucial sample review stages.

- Production Errors: Rushed production lines lead to a higher defect rate.

- Sky-High Shipping Costs: You will likely be forced to use air freight, which can be 5-10 times more expensive than sea freight.

- Missed Sales: Even with air freight, delays can mean your products arrive after the peak shopping season has already started.

How Does Ordering Early Save You Money?

You understand the timing argument, but you're still focused on the upfront cost. Your primary goal is to get the best possible unit price from your supplier. It seems logical that negotiating during the factory's "off-season" would give you more leverage, but you're not sure how much of a difference it really makes.

Ordering your winter accessories in the spring is one of the most effective cost-saving strategies you can employ. It allows you to take advantage of lower raw material costs, better factory capacity, and, most significantly, the massive savings of using sea freight instead of being forced into last-minute air shipping.

The financial benefits are multi-faceted. First, factories are often quieter in the spring. This means we at Shanghai Fumao Clothing have more flexibility in our production schedule and can sometimes offer more competitive pricing. Second, yarn and other raw material suppliers are not yet facing peak demand, so costs can be more stable. But the single biggest saving comes from logistics. An order placed in the spring can be shipped comfortably by sea, which is vastly cheaper than air. An order placed in late summer will almost certainly require air freight to arrive on time, a cost that can completely erase your profit margins.

How much cheaper is sea freight than air freight?

The difference is substantial. While prices fluctuate, a general rule of thumb provided by logistics experts at companies like Flexport is that air freight can be 5 to 10 times more expensive than sea freight for the same volume. For a bulk order of accessories, this can mean the difference between a profitable season and a net loss. By ordering early, you are essentially choosing the most economical shipping method available.

Does ordering early give me more negotiation power?

Yes, it gives you the power of time. When you are not in a rush, you can take the time to get quotes from multiple suppliers. You can negotiate terms more effectively because the supplier knows you are a well-prepared, professional partner planning for a long-term relationship, not a desperate buyer needing a rush job. This positions you as a more desirable client and can lead to better overall terms.

What Are the Quality and Design Advantages of an Early Start?

You have a very specific vision for your new winter scarf. The yarn has to have a particular softness, the color needs to be just right, and the custom woven label must be perfectly placed. You're worried that if you rush the process, you'll have to compromise on these details and the final product won't live up to your brand's quality standards.

Starting early gives you the invaluable gift of time for refinement and perfection. It allows for a multi-stage sampling process where you can physically touch, test, and revise your product until it is absolutely perfect. This iterative process is the secret to developing a truly high-quality product and is the first thing to be sacrificed in a rushed timeline.

A professional development process should never rely on a single prototype. The first sample you receive is a starting point. Maybe the fit of the hat isn't quite right, or the color of the glove is slightly off. An early start gives you time to provide feedback and have your supplier create a second, or even third, revised sample. This ensures that when you approve the final pre-production sample, you are 100% confident that it is perfect. This meticulous approach, a standard in professional product development as taught by institutions like the Fashion Institute of Technology (FIT), is only possible when you are not racing against the clock.

How does this improve material sourcing?

When you start early, you have access to the full range of available materials, not just what's currently in stock. If you want a specific, custom-dyed merino wool yarn for your beanies, the yarn mill needs time to produce it. By ordering in the spring, you give your factory partner enough time to source the absolute best materials for your product, rather than being forced to make a last-minute substitution.

Can an early start help with more complex designs?

Definitely. If your design involves a complex jacquard knit pattern, a custom-molded buckle, or a unique embroidery, these elements take extra time to set up and sample correctly. An early start allows the factory's technicians the time they need to perfect the machine setup and programming required for these intricate details, ensuring the final product is executed flawlessly.

How Does This Strategy Reduce Overall Business Risk?

As a business owner, your world is filled with uncertainty. You're constantly managing supply chain disruptions, changing consumer trends, and unexpected delays. The thought of adding a self-inflicted crisis by ordering critical seasonal inventory too late is a major source of stress. You want a strategy that brings predictability and control to your operations.

Adopting a "reverse season" ordering calendar is a powerful risk mitigation strategy. It builds a crucial buffer into your timeline that can absorb unforeseen delays—such as shipping congestion, raw material shortages, or production issues—without jeopardizing your entire season. It replaces panic and uncertainty with control and predictability.

The global supply chain is complex and can be unpredictable. A typhoon can close a port for a week. A national holiday can shut down a factory. A customs backlog can add days to your delivery time. If your timeline is already razor-thin, any one of these common issues can be catastrophic. But if you have built a 2-3 month buffer into your schedule by ordering early, you can absorb these delays without breaking a sweat. Your products will still arrive well before you need them. This strategy, as advocated by supply chain experts in publications like Supply Chain Dive, is fundamental to building a resilient and scalable business.

How does this help with marketing and sales planning?

When your inventory arrives in your warehouse in September or October, your marketing team has a huge advantage. They can conduct photoshoots with the actual products, prepare email campaigns, and plan their social media calendar weeks in advance. Your sales team can confidently pre-sell to wholesale accounts. This preparedness allows you to launch your winter collection with maximum impact the moment the first cold front arrives.

What if I'm a new brand and can't plan that far ahead?

This is a common challenge, but it's still crucial to start as early as you possibly can. Have a conversation with a potential manufacturing partner like us. Be transparent about your situation. A good partner will work with you, perhaps suggesting designs that use readily available materials to shorten the timeline or offering a smaller initial order quantity. But the principle remains the same: the more time you can give your supplier, the better, safer, and more cost-effective your result will be.

Conclusion

The secret to a successful winter retail season lies in the decisions you make in the spring. By ordering your winter accessories between February and April, you are not just placing an order; you are executing a professional, strategic plan. This 6-to-9-month lead time empowers you to save significant money, develop a higher-quality product, and build a resilient supply chain that is insulated from common risks. It allows you to trade the chaos and compromise of last-minute ordering for the calm confidence of being fully prepared.

At Shanghai Fumao Clothing, our most successful and long-lasting partnerships are with brands who understand and embrace this professional timeline. We are structured to work with you on this "reverse season" calendar to ensure every detail is perfect. If you are planning for next winter and want a reliable, high-quality manufacturing partner to help you execute your vision flawlessly, now is the perfect time to start the conversation. Please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com to begin planning your most successful season yet.