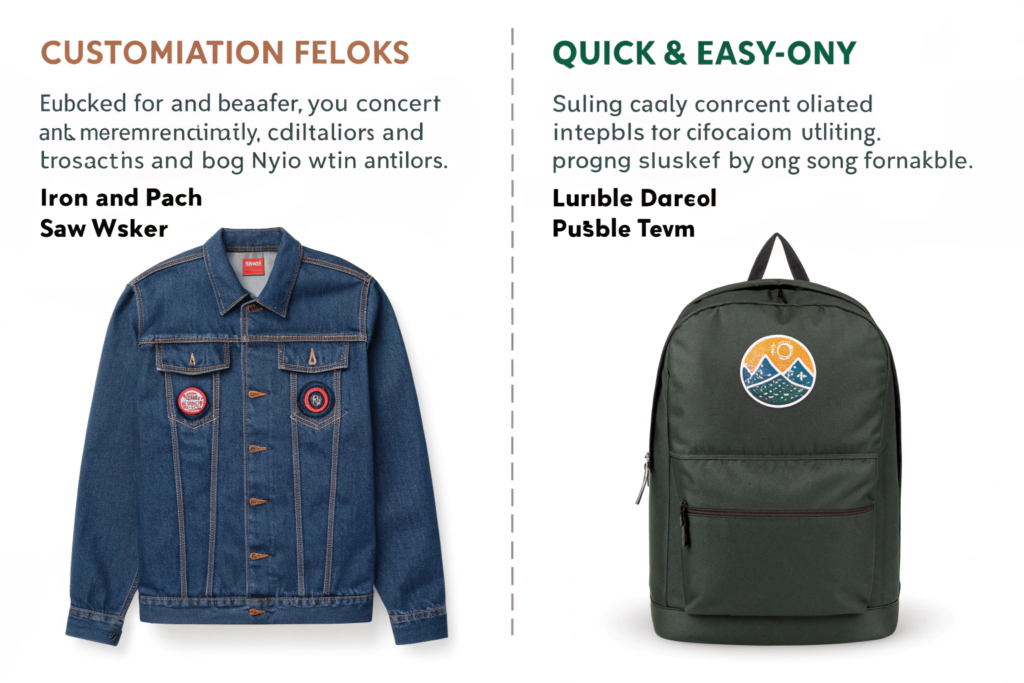

You've found the perfect embroidered patch to customize your jacket or backpack. It’s a statement piece that will showcase your personality. But then you're faced with a critical choice on the product page: iron-on backing or sew-on? You're worried about making the wrong decision. What if the iron-on patch falls off after one wash? What if you don't have the skills to sew on a patch correctly? This uncertainty can turn a fun, creative project into a source of anxiety.

The choice between an iron-on and a sew-on patch comes down to a simple trade-off: convenience versus durability. Iron-on patches offer speed and ease of application, making them perfect for quick customizations on standard fabrics like cotton and denim. Sew-on patches provide superior, permanent durability, making them the essential choice for non-ironable fabrics, heavy-use items, and long-term applications.

Understanding the strengths and weaknesses of each type is key to ensuring your creative vision lasts. It's not that one is universally "better" than the other; they are simply different tools for different jobs. As a manufacturer that produces both types of patches for our clients at Shanghai Fumao Clothing, we want to empower you to make the best choice for your specific project. Let's break down the pros and cons of each method.

What Are the Pros and Cons of Iron-On Patches?

You're excited to personalize a new tote bag for an event this weekend. You need a fast, simple solution that doesn't require any special skills or equipment beyond what you already have at home. The idea of having to learn how to sew, buy a needle and thread, and spend time carefully stitching feels like a major barrier.

Iron-on patches are the champion of convenience. Their primary advantage is an incredibly fast and easy application process that requires only a standard household iron. This makes them highly accessible for beginners and ideal for quick, on-the-spot customizations.

The magic of an iron-on patch lies in its heat-activated adhesive backing. When you apply heat, the adhesive melts and bonds with the fibers of the fabric, securing the patch in place in minutes. However, this convenience comes with trade-offs. The adhesive bond can weaken over time with repeated washing and flexing, and it simply won't work on certain materials. This makes them less suitable for items that will see heavy use or be washed frequently. Understanding these limitations is key, as we'll explore further in When Should I Absolutely Use a Sew-On Patch?.

What are the main advantages of iron-on patches?

The benefits of iron-on patches are clear and compelling for many projects:

- Speed and Ease: Application takes just a few minutes with a common household item. There's no learning curve.

- Clean Appearance: When applied correctly, there are no visible threads, giving the patch a clean, seamless look as if it were part of the original garment.

- No Special Skills Required: Anyone who can use an iron can apply an iron-on patch, making it a perfect entry point for DIY customization. This accessibility is a major selling point, as noted by craft supply retailers like JOANN Fabric and Craft Stores.

What are the biggest disadvantages?

You must be aware of the limitations before choosing an iron-on patch:

- Limited Durability: The adhesive bond is not permanent. It can degrade over time, especially with machine washing and drying, causing the edges of the patch to peel.

- Fabric Incompatibility: The high heat required for application can damage delicate or synthetic fabrics like nylon, rayon, silk, and leather. They are best suited for cotton, denim, and polyester blends.

- Potential for Residue: If you try to remove an iron-on patch, it can leave behind a sticky, difficult-to-clean residue. For advice on removal, resources like Good Housekeeping offer some useful tips.

What Are the Pros and Cons of Sew-On Patches?

You're customizing a leather motorcycle jacket or a rugged canvas backpack that you plan to use for years. This item will be exposed to the elements, friction, and stress. The idea of a patch peeling off during a trip or after a few months is unacceptable. You need a solution that is as tough and permanent as the item it's attached to.

Sew-on patches are the gold standard for durability and permanence. By physically stitching the patch to the fabric with thread, you create a mechanical bond that is incredibly strong and will last as long as the garment itself. This makes them the only choice for certain materials and high-stress applications.

The strength of a sew-on patch lies in the thread. Each stitch reinforces the connection, distributing stress across the entire perimeter of the patch. This method is not reliant on adhesives and is compatible with virtually any fabric you can pass a needle through. The trade-off, of course, is the time and effort required for application. While it can be done by hand or with a sewing machine, it requires more skill and patience than using an iron. This is the ultimate "buy it for life" option for patch application.

What are the main advantages of sew-on patches?

The reasons to choose a sew-on patch are all about long-term performance:

- Superior Durability: A properly sewn patch is permanent. It will not peel, lift, or fall off, even with heavy use and repeated machine washing.

- Universal Fabric Compatibility: You can sew a patch onto almost anything, including leather, nylon, denim, canvas, and delicate fabrics that would be destroyed by an iron. This versatility is why they are used on everything from military uniforms to high-end fashion, as noted by custom patch makers like The Studio.

- Removability: Although it takes time, a sew-on patch can be removed by carefully cutting the threads, leaving the garment underneath undamaged and free of residue.

What are the biggest disadvantages?

The challenges of sew-on patches are primarily in the application process:

- Time and Effort: Hand-sewing a patch can be a time-consuming process, especially for beginners. Using a sewing machine is faster but requires access to and knowledge of the machine.

- Skill Required: While basic hand-sewing is a learnable skill, achieving a neat, even stitch takes practice. A sloppy sewing job can detract from the look of the patch.

- Visible Stitches: The thread will be visible around the border of the patch. While this can be a desirable stylistic element (a "DIY" or "punk" aesthetic), it may not fit the clean look you want to achieve.

How Do I Choose the Right Patch for My Project?

You're standing at a crossroads, patch in hand. You understand the pros and cons of each type in theory, but you're still not 100% sure which is the right call for your specific situation. You need a clear, simple decision-making framework to guide you to the correct choice and ensure your project is a success.

To choose the right patch, ask yourself two key questions: 1) What is the fabric of the item? and 2) How will the item be used and cared for? The answers will point you directly to the best solution.

Use this simple guide to make your decision:

| Choose IRON-ON if... | Choose SEW-ON if... |

|---|---|

| You are applying it to cotton, denim, or canvas. | You are applying it to leather, nylon, vinyl, or silk. |

| You need a quick and easy application. | Durability is your #1 priority. |

| The item will be washed infrequently and gently. | The item will be washed often or used heavily (e.g., a work jacket). |

| You want a clean, seamless look with no visible threads. | You want the ability to remove it cleanly in the future. |

| The patch is for a temporary event or fashion statement. | The patch is for a permanent collection or heirloom item. |

This framework simplifies the choice. For a quick customization on a denim jacket for a concert, iron-on is perfect. For a patch on a nylon backpack you'll take hiking for the next decade, sew-on is the only reliable option.

Can I sew on an iron-on patch?

Yes, absolutely! This is often the best-of-both-worlds solution. You can first use the iron-on backing to temporarily tack the patch perfectly in place—no pins needed. Then, you can sew around the edge for maximum, permanent security. Many patch enthusiasts, including those on forums like Reddit's r/patches, swear by this hybrid method. It combines the easy positioning of an iron-on with the unmatched durability of a sew-on.

What if my patch doesn't have a backing?

If a patch is sold simply as "embroidered patch" with a plain fabric or plastic backing, it is a sew-on patch by default. It has no adhesive and must be attached with thread. As a manufacturer, we at Shanghai Fumao Clothing always ensure the backing type is clearly specified, but if you're ever in doubt, assume it's a sew-on.

Conclusion

The choice between iron-on and sew-on patches is a classic case of choosing the right tool for the job. Iron-on patches offer unparalleled speed and convenience for quick projects on standard fabrics, while sew-on patches provide the ultimate in durability and versatility for any material or long-term application. By evaluating your fabric type and how you'll use the item, you can confidently select the method that ensures your patch looks great and stays put for as long as you need it to. And remember the pro tip: combining both methods gives you an easy, perfectly placed, and permanent application every time.

Whether you're a brand looking to produce patches for your apparel line or an individual embarking on a creative project, understanding these fundamentals is key. If you are looking to create high-quality custom patches and need a manufacturing partner who understands the nuances of both backing types, we are here to help. Please feel free to reach out to our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your patch project.