You've just received an email with the subject line: "Pre-Shipment Inspection Report for Order PO-123." You open it and see a multi-page document filled with tables, percentages, and photos of your products with red arrows pointing to tiny details. You see terms like "AQL 2.5," "Major Defects: 3," "Minor Defects: 7," and a final result of "PENDING." What does it all mean? Did the inspection pass or fail? Is your entire order a disaster?

How can you interpret a fashion accessory inspection report? You must understand that it's not a simple "pass/fail" test, but a statistical risk assessment tool. You need to focus on four key areas: 1) understanding the AQL levels you've set, 2) checking the sample size and accept/reject numbers, 3) analyzing the specific defects found, and 4) making an informed final decision based on the evidence. As the owner of Shanghai Fumao Clothing, we see these reports as a crucial part of our transparent partnership. They are a health check-up for your production, and knowing how to read the results is vital.

Is this just a complicated document for statisticians? Not at all. Let's break down how to read an inspection report into four clear, manageable steps.

What Are the AQL Defect Classifications?

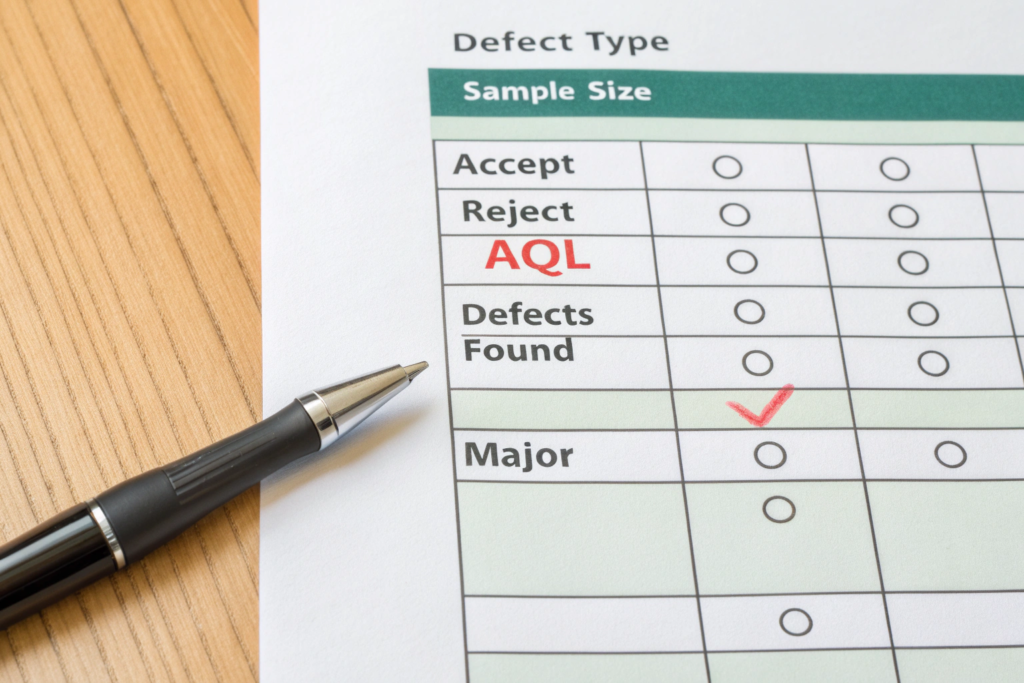

Before you can judge the results, don't you need to understand how defects are categorized? The entire report is built around a system called AQL (Acceptance Quality Limit), which classifies defects into three levels of severity. You, the client, decide the acceptable limit for each level. A typical setup is Critical 0%, Major 2.5%, and Minor 4.0%. Understanding what falls into each category is the first step to interpreting the report.

What is a "Critical" Defect?

Why is the tolerance for this always zero? A Critical Defect is the most serious type of flaw. It's an issue that could cause harm to the end-user or violates mandatory safety regulations (like the CPSIA in the USA). For our products, this could be a sharp metal edge on a belt buckle, a sewing needle accidentally left in a hat, or the use of a banned chemical in a dye. The discovery of even one critical defect is grounds for failing the entire inspection.

What is a "Major" Defect?

What makes a defect "Major"? A Major Defect is a significant flaw that would likely cause a customer to be dissatisfied and return the product. It's a problem that affects the usability, saleability, or overall appearance of the accessory. Examples include a non-functioning zipper on a bag, a very noticeable printing error on a scarf, or a stone missing from an embellished hair clip. These are the defects that can damage your brand's reputation for quality.

How Do You Read the Main Results Table?

Now that you know the defect types, how do you read the report's main summary? You'll find a table that shows the "numbers game." Based on your total order quantity and your chosen AQL levels, a statistical standard (like ISO 2859-1) determines how many units the inspector will randomly check (the Sample Size). This same standard then provides the maximum number of defects that can be found for the lot to be "Accepted."

Your job is to compare the number of defects the inspector found to the number that is allowed.

What is a Practical Example?

Let's walk through a common scenario to make it clear.

- Your Order: 4,000 knit beanies.

- Your AQL: Major 2.5 / Minor 4.0.

- Sample Size (determined by the standard): 200 pieces.

- Accept/Reject Numbers (provided in the report):

- Major 2.5: Accept if 10 or fewer defects are found. Reject if 11 or more.

- Minor 4.0: Accept if 14 or fewer defects are found. Reject if 15 or more.

- Inspector's Findings: The inspector checks the 200 beanies and finds 5 Major defects and 12 Minor defects.

What is the Verdict in This Case?

How do you interpret this specific result?

- For Major defects, 5 found is less than the "Accept" number of 10. Therefore, the inspection PASSES for Major defects.

- For Minor defects, 12 found is less than the "Accept" number of 14. Therefore, the inspection PASSES for Minor defects.

The overall result for this inspection would be a clear "PASS." This is the kind of result we always aim to deliver through our own internal quality checks, ensuring consistency in manufacturing.

Why Must You Analyze the Defect Descriptions and Photos?

So, the numbers say "pass." Does that mean you should immediately approve the shipment? Not so fast. The numbers only tell you how many defects were found, not what they are. The most important part of your job as a brand owner is to look at the defect photos and descriptions.

The inspection report will include a detailed section with clear photos of every single Major and Minor defect found. This is your chance to see with your own eyes what the issues are. You might find that the numbers "pass," but the type of Major defect found is something you find completely unacceptable for your brand. Conversely, you might find the numbers "fail," but the defects are all borderline issues that you are willing to accept.

What Should You Look for in the Defect Photos?

What are the red flags to watch out for?

- Clustering of Defects: Are all the defects of the same type? If all 5 Major defects are the exact same crooked logo on a baseball cap, it points to a systemic problem in one part of the production line that needs to be addressed, even if the report "passes."

- Severity: Look at a "Major" defect. Is it truly major in your eyes? Would your customer return the product for this? Your opinion is the one that matters most.

- Location: A small flaw on the inside of a hat is very different from the same flaw right on the front. The location of the defect is as important as the defect itself.

What if You Disagree with the Inspector's Classification?

Can you argue with the inspector's judgment? Yes, to a degree. An inspector classifies defects based on their training and standard guidelines. However, you are the ultimate expert on your own product. For example, an inspector might classify a specific color variation as a "Major" defect. But you might look at it and decide that it's a minor issue that you can live with. You have the final say. This is why a clear, approved pre-production sample is so important—it's the "golden standard" that everything is judged against.

How Do You Make the Final "Ship or Hold" Decision?

After analyzing the numbers and the photos, you have to make the final call. The inspector will give an overall result, which is usually one of three options: PASS, FAIL, or PENDING. But remember, this result is a recommendation. The final decision is always yours. Based on the report, you will instruct your supplier on how to proceed.

What Are Your Options if the Inspection Fails?

If the report comes back as "FAIL," what can you do? You have several options, and this is where you need to communicate with your manufacturing partner.

- Reject the Entire Lot: This is a very extreme and rare option, usually reserved for situations with Critical defects or catastrophic quality failure.

- Request a 100% Sort and Rework: This is the most common solution. You ask the factory to go through the entire production lot (not just the sample), pull out all the defective pieces, and either fix (rework) them or replace them.

- Negotiate a Discount: If the defects are cosmetic and you believe you can still sell the products (perhaps at a slight discount), you can negotiate a discount on the defective items or the entire order from your supplier to compensate. This is a key part of handling unexpected issues.

- Accept the Goods As-Is: If you analyze the "Major" defects and decide they are acceptable to your brand's standard, you have the right to overrule the "FAIL" result and accept the shipment.

How Can You Prevent Failures in the First Place?

Isn't prevention better than a cure? Yes. The best way to ensure a "PASS" result is to work with a high-quality, transparent factory from the start. A good factory will have its own internal QC team that inspects the products before your third-party inspector even arrives. At AceAccessory, our goal is to find and fix any issues ourselves, so that the final inspection report is simply a confirmation of the quality we've already built into the product.

Conclusion

So, how do you interpret a fashion accessory inspection report? Is it a document to be feared? Not at all. It is a document that empowers you.

By understanding the AQL framework, analyzing the statistical results, and, most importantly, critically reviewing the qualitative defect photos, you can transform the report from a confusing set of numbers into a powerful tool for managing your quality and protecting your brand. It facilitates a clear, fact-based conversation with your manufacturing partner and ensures that the products you receive are the products you designed.

We believe in this process wholeheartedly. If you're looking for a partner who welcomes this level of scrutiny and is committed to delivering quality that passes the test, we're ready to work with you. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.