Of course. This is an excellent and highly technical question. It gets to the very heart of what makes a structured cap look great and last long. As a manufacturer of headwear, I can tell you that the interlining is the unsung hero of a structured cap. It's an invisible component, but choosing the right one is one of the most critical decisions in ensuring the final product has the perfect shape, feel, and durability.

Have you ever noticed how some baseball caps have a crisp, tall, and perfectly rounded front profile that never seems to collapse, while others are soft and floppy? That sharp, permanent shape doesn't come from the outer fabric alone. It comes from a hidden internal component called interlining, and for structured caps, the specific type used is most often buckram.

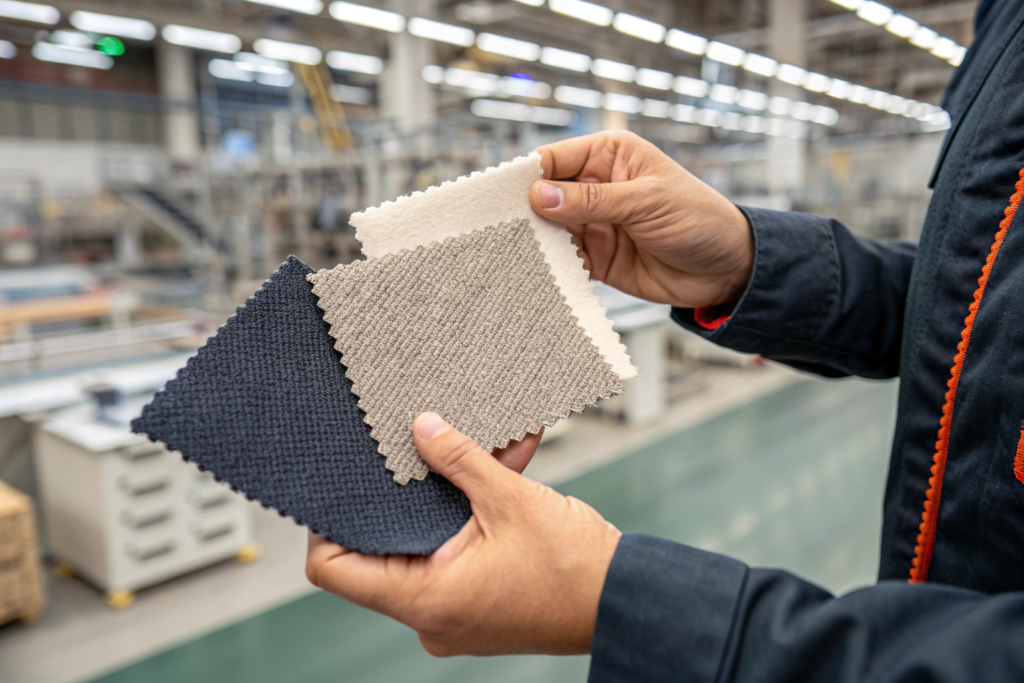

So, how do you choose the right interlining? It's not a one-size-fits-all decision. Choosing the right interlining involves balancing the desired stiffness and profile of the cap with the comfort of the wearer and the nature of the outer fabric. As the owner of Shanghai Fumao Clothing, this is a detailed conversation we have for every new cap style we develop. The choice of buckram is a technical decision that has a massive impact on the final look, feel, and quality of the product.

Is it just a simple piece of stiff fabric? Not at all. Let's dive into the details and explore the four key considerations for selecting the perfect internal structure for your caps.

What Exactly is Buckram and Why is it the Standard?

Before you can choose the right one, shouldn't you first understand what you're working with? While "interlining" is the general term for a fabric used to provide shape and support, in the world of structured caps, the specific material used is almost always buckram.

What is buckram? It's a stiff, coarse cotton fabric that has been treated with a sizing agent (like starch or a modern resin) to give it a rigid, paper-like quality. It's essentially the internal skeleton of the cap's front two panels. It's strong, lightweight, and holds its shape exceptionally well, even after getting wet. This unique combination of properties has made it the undisputed industry standard for creating the classic "structured" cap profile.

Isn't it fascinating that this hidden material is the true source of the cap's iconic shape? Understanding its role is the first step in making an informed choice. This is a level of detail we pride ourselves on, just as we do when selecting the right materials for summer hats.

Is All Buckram the Same?

No, and this is the most critical point. Buckram comes in different weights and stiffness levels. We typically classify it as Soft Buckram, Medium Buckram, and Hard Buckram.

- Soft Buckram: Offers gentle support for a more relaxed, "unstructured" or "low-profile" look.

- Medium Buckram: Provides a good balance of structure and comfort. It creates a defined shape that isn't overly rigid.

- Hard Buckram: This is the most rigid option. It's used to create the tall, stiff, "pro-style" profile seen on many on-field athletic caps. It holds its shape perfectly but is less pliable.

How is the Buckram Applied?

How does it stick to the fabric? The buckram is typically applied to the back of the front two fabric panels before the cap is sewn together. In modern production, we often use fusible buckram, which has a heat-activated adhesive on one side. The fabric and buckram are placed in a heat press, which permanently fuses them together into a single, structured panel. This is a key step we monitor closely during the sample evaluation process.

What Cap Profile and Style Are You Trying to Achieve?

The most important question you must answer is: what do you want your cap to look like? The choice of interlining is directly tied to the final silhouette you want to create.

Are you aiming for a high-profile, athletic look, or a more casual, low-profile style? The "profile" of a cap refers to the height of the crown. A high-profile cap sits tall on the head, while a low-profile cap has a shallower crown that fits closer to the scalp. The stiffness of the buckram is the primary tool we use to engineer this profile.

Doesn't the end-use of the cap dictate its style? A cap for a professional sports team will have very different structural needs than a casual fashion cap.

When Should You Choose Hard Buckram?

For what styles is hard buckram best? You should choose Hard Buckram if you want to create a classic, high-profile or mid-profile structured cap. This is the standard for:

- Official on-field sports caps (like those used in Major League Baseball).

- Many streetwear and hip-hop style caps (like classic snapbacks).

- Brand promotional caps that need a large, flat front for a prominent logo.

The hard buckram ensures the front of the cap remains a tall, smooth canvas.

When Should You Choose Medium or Soft Buckram?

When is a softer option better? You should opt for Medium or Soft Buckram if you are designing a low-profile cap, often called a "dad hat" or "unstructured cap" (though even these often have some soft support). This is ideal for:

- More casual, fashion-oriented brands.

- Caps where comfort and a relaxed fit are the top priorities.

- Designs that aim for a more vintage or worn-in look.

A softer interlining creates a shape that conforms more closely to the wearer's head.

How Does the Outer Fabric Influence Your Choice?

Can you use the same interlining for any fabric? Not if you want the best result. The weight and type of your chosen outer fabric must be considered in partnership with the interlining. The goal is to create a harmonious relationship between the two layers, not a battle.

If you use a very stiff buckram with a very thin, lightweight outer fabric, you can get undesirable results like bubbling or wrinkling. The stiff interlining can overpower the delicate fabric. Conversely, if you use a very soft buckram with a heavy, thick fabric like wool or corduroy, the interlining might not be strong enough to provide any meaningful shape.

Isn't it crucial that these two materials work together? This is where the expertise of your manufacturer is invaluable.

What Interlining Works Best for Heavy Fabrics?

If your cap is made from a heavy material like wool, thick canvas, or corduroy, what should you do? These fabrics have some natural structure of their own. You can often use a Medium Buckram to achieve a structured look. Using a Hard Buckram can sometimes create a front panel that feels overly thick and rigid, like a helmet. The goal is to support the fabric, not fight it.

What About Lightweight Fabrics?

What if you're using a lightweight material like nylon, polyester, or a thin cotton twill? These fabrics have very little natural structure. To create a crisp, high-profile shape with these materials, you will almost certainly need to use Hard Buckram. The stiff interlining will provide all of the shape, while the lightweight outer fabric acts as a thin, decorative skin. This is the standard combination for most modern performance sports caps.

How Does Interlining Affect Embroidery and Embellishments?

Are you planning to put a logo on the front of the cap? Of course you are. The type of embellishment you choose has a direct relationship with the interlining.

The front panel of a structured cap is the prime real estate for branding. Whether you are using traditional flat embroidery, modern 3D puff embroidery, or a woven patch, the interlining provides the stable foundation needed for a clean, high-quality result.

Have you ever seen embroidery on a soft fabric that looks puckered or distorted? This is what happens when there isn't enough support. A firm interlining is the secret to sharp, professional-looking embroidery.

Why is Hard Buckram Best for 3D Puff Embroidery?

What if you want that popular, raised 3D embroidery? For this technique, Hard Buckram is not just recommended; it's essential. 3D puff embroidery involves stitching over a piece of foam to create the raised effect. This process puts a lot of tension on the fabric. The rigid foundation of the hard buckram prevents the fabric from puckering or distorting under this tension, resulting in a sharp, clean, and impressive 3D logo.

What About for Patches or Prints?

What if you're applying a patch? A firm foundation is still your best friend. Whether you are applying a woven patch, a leather patch, or a PVC patch, the smooth, stable surface created by a Medium or Hard Buckram ensures the patch lies flat and adheres properly. For screen printing or heat transfers, this stable surface is also crucial for achieving a clear, undistorted image. This is a key consideration when planning your branding strategy.

Conclusion

So, how do you choose the right interlining for your structured cap? Is there one simple answer? No. It is a thoughtful balancing act. You must consider the final style and profile you want to achieve, the weight and type of your outer fabric, and the embellishment you plan to use.

The best approach is to have a detailed conversation with your manufacturing partner. By clearly communicating your vision, you can leverage their technical expertise to select the perfect buckram—soft, medium, or hard—that will act as the perfect, invisible foundation for your cap. It's a small detail that makes all the difference in creating a product that looks professional, feels comfortable, and proudly carries your brand's name.

We consider this level of technical guidance a core part of our service. If you're ready to build the perfect cap, from the inside out, we're ready to help. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.