For brands and importers in the fashion accessory business, maintaining the pristine appearance of your products is essential for customer satisfaction and brand reputation. When it comes to belt buckles, tarnish—that dull, discolored film that appears on metal—is a common and frustrating issue that can turn a premium accessory into a disappointing purchase. How can you ensure the belt buckles you source remain bright and beautiful for your customers over time?

Preventing belt buckle tarnish requires a dual approach: selecting the right plated or solid metal during manufacturing and providing clear, effective aftercare instructions to the end-user. The battle against tarnish is won through proactive choices in materials, protective coatings, and proper storage. As a manufacturer, your commitment to quality plating and finishing processes is the first and most critical line of defense.

Tarnish occurs when metals, especially brass, copper, and certain alloys, react with sulfur-containing substances in the air, moisture, or even skin oils. Understanding this process empowers you to make informed decisions from the design and sourcing stage all the way to the consumer's home. This guide outlines a comprehensive strategy to deliver belt buckles that resist tarnish and maintain their luster.

How to Choose the Right Materials and Platings During Production?

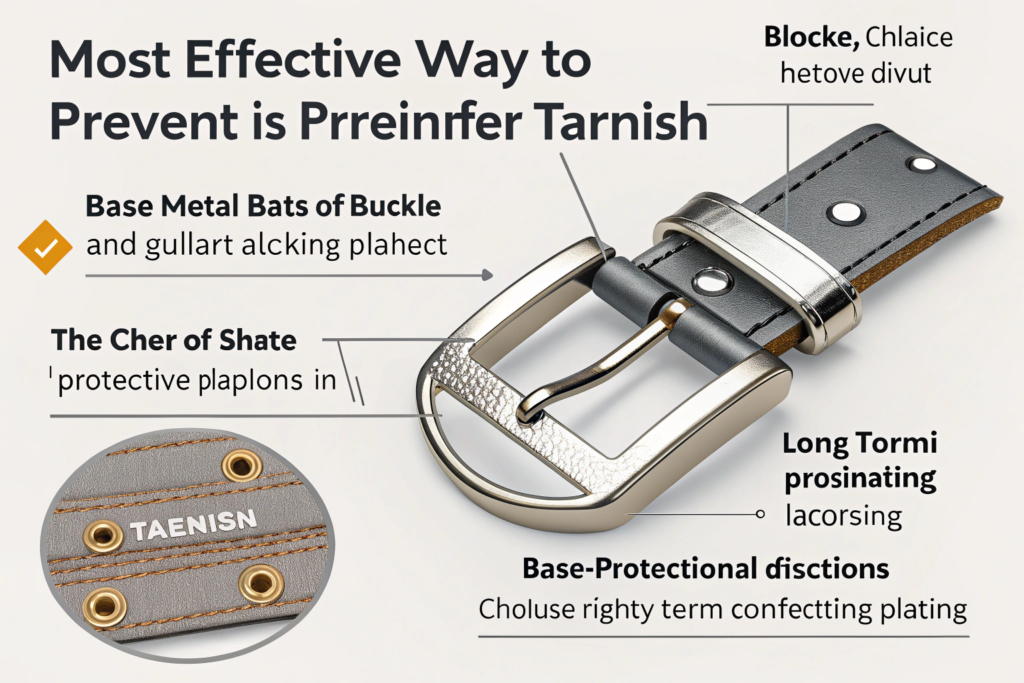

The most effective way to prevent tarnish is to engineer it out of the product from the start. The choice of base metal and the quality of the protective plating are the foundational decisions that determine a buckle's long-term appearance.

For a bright, silvery finish that is highly tarnish-resistant, stainless steel is an excellent base material. It contains chromium, which forms a passive oxide layer that protects the metal beneath. For gold and antique finishes, a high-quality plating over a suitable base metal is key. The thickness and type of plating are crucial. A common industry standard is to use a nickel underplating followed by a gold or silver plating of at least 0.5 microns. The nickel layer provides an excellent barrier against corrosion from the base metal (often zinc alloy or brass) migrating through. For a superior finish, consider PVD (Physical Vapor Deposition) coating. This advanced process creates an extremely thin, hard, and durable ceramic-like layer that is highly resistant to tarnish, wear, and fading, making it ideal for premium accessories.

What Role Do Clear Coatings and Lacquers Play?

After plating, applying a protective clear coat or lacquer is a vital final step. This transparent layer acts as a physical barrier, sealing the metal off from air, moisture, and contaminants. Not all lacquers are equal. It is essential to use a high-quality, water-resistant lacquer formulated for metal that can withstand flexing without cracking. A cracked lacquer layer will allow tarnish to form in the compromised areas. During manufacturing, the application must be even and complete, covering every surface, including the back and edges of the buckle. This finishing step, while adding cost, dramatically extends the buckle's life and is a hallmark of quality manufacturing at facilities like ours.

Why is Base Metal Quality Important?

The quality of the metal underneath the plating matters immensely. Inferior, porous base metals can contain impurities that eventually cause spotting and blistering under the plating, leading to premature tarnish. Using a high-quality zinc alloy or brass that is properly prepared and polished before plating ensures a smooth, stable foundation. A poor foundation will inevitably lead to a flawed finish, no matter how good the plating appears initially. This is a critical checkpoint in the quality control process that discerning manufacturers enforce.

How Should Belt Buckles Be Stored and Handled Post-Production?

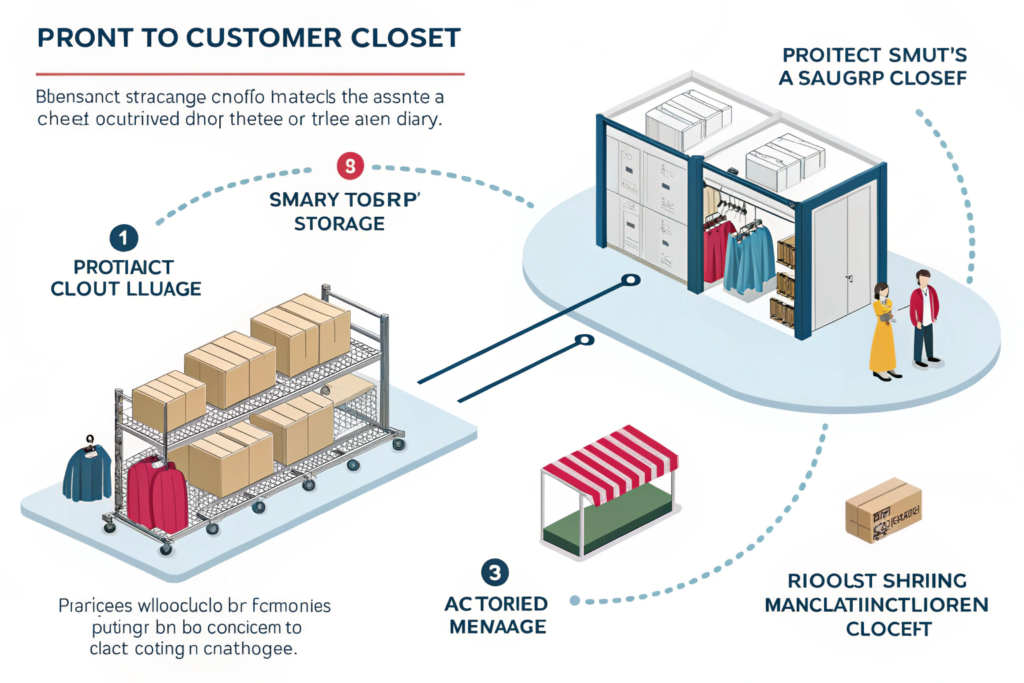

The journey from your factory to the customer's closet presents multiple opportunities for tarnish to begin. Implementing smart storage and packaging protocols is essential to ensure your product arrives in perfect condition.

Immediately after the final lacquer coat has cured, buckles should be handled with cotton gloves to prevent fingerprints, which contain acids and oils that can initiate tarnish. For storage and packaging, the environment should be cool, dry, and stable. Humidity is a major accelerator of tarnish. Individually wrapping each buckle in anti-tarnish paper is a highly effective practice. This paper is impregnated with compounds that neutralize tarnish-causing gases in the air. For added protection, especially during long-term storage or sea freight, including small silica gel desiccant packets in the packaging absorbs excess moisture.

What is the Best Way to Package Belt Buckles for Retail?

The retail packaging itself should be part of the preservation strategy. Avoid sealing buckles in airtight plastic pouches unless you are certain all moisture has been eliminated, as trapped humidity can cause condensation. Instead, use packaging that allows for some air circulation or is lined with anti-tarnish materials. Providing a soft storage pouch with the belt, made from felt or another non-abrasive material, encourages the customer to store the belt properly after purchase, extending its life. Clear care instructions on or inside this pouch reinforce your brand's commitment to quality.

How Does Logistics Impact Tarnish Risk?

Be mindful of the logistics chain. Shipping containers can experience extreme temperature fluctuations, leading to condensation (known as "container sweat"). Using climate-controlled shipping or ensuring desiccant is used in the master cartons can mitigate this risk. Communicating with your logistics partner about the need to store goods in a dry warehouse is also important. Proactive measures at this stage prevent customer complaints about products arriving in less-than-perfect condition.

What Care and Maintenance Instructions Should You Provide to Customers?

Empowering your customers with knowledge is the final, crucial step in the anti-tarnish chain. Even the best-plated buckle will eventually show wear if mistreated. Clear, simple care instructions help preserve the product and enhance customer satisfaction.

Provide instructions that advise customers to:

- Wipe the buckle gently with a soft, dry cloth after each wear to remove sweat, oils, and environmental pollutants.

- Store the belt in a cool, dry place, ideally in the provided pouch, away from humidity (like bathrooms) and direct sunlight.

- Avoid contact with chemicals such as perfumes, hairsprays, lotions, and household cleaners, as these can break down the protective lacquer.

- Remove the belt before swimming (chlorine and saltwater are highly corrosive) and before strenuous activity that causes excessive sweating.

What Should Customers Avoid Doing?

Equally important is telling customers what not to do. Explicitly advise against using:

- Harsh chemical cleaners or jewelry dips, which can strip the protective lacquer.

- Abrasive materials like rough paper towels, steel wool, or toothpaste, which will scratch the finish.

- Excessive polishing, as frequent rubbing can wear through thin plating over time.

Recommending a specific, mild cleaner designed for plated jewelry (applied sparingly with a soft cloth) can be helpful for occasional deep cleaning if you are confident in the product.

How Can Clear Instructions Build Brand Trust?

These care instructions do more than preserve the belt; they build brand trust. They show that you are invested in the longevity of your product and the customer's experience. Including this information on a branded card or tag positions your brand as knowledgeable and quality-focused. It turns a potential problem (tarnish) into an opportunity for positive engagement and reduces the likelihood of returns or negative reviews based on improper care.

How to Handle Tarnish if It Does Occur?

Despite all precautions, some tarnish may eventually appear, especially on frequently worn items. Providing a clear path for remediation shows excellent customer service.

For light tarnish on lacquered buckles, often a gentle wipe with a soft, slightly damp cloth followed by immediate drying is sufficient. For unlacquered brass or copper buckles (where a patina may be desirable), you can recommend a dedicated metal polish and a very soft cloth, with the caveat that polishing will remove some metal over time. The key advice is gentleness to avoid damaging the underlying plating. For PVD-coated buckles, tarnish is very unlikely, and cleaning should only involve mild soap, water, and a soft cloth.

When is Professional Refinishing the Best Option?

For valuable or sentimental belts where the plating has worn through, professional replating is an option. While not typically offered by clothing brands, knowing that this service exists allows you to provide a more complete answer to a dedicated customer. The best strategy, however, is to focus on the preventative measures in manufacturing and care that make refinishing unnecessary for the life of the product.

Why is a Proactive Quality Guarantee Important?

Consider offering a warranty against manufacturing defects that lead to premature tarnishing or plating failure. This guarantee, backed by your rigorous quality control standards, provides ultimate peace of mind to your customers and demonstrates the confidence you have in your sourcing and production partners. It transforms a potential weakness of metal accessories into a compelling sales point about durability and craftsmanship.

Conclusion

Ensuring your belt buckles do not tarnish is a comprehensive process that begins on the factory floor and continues through to the end-user's care routine. It hinges on selecting high-quality materials and platings, implementing protective lacquers, utilizing intelligent packaging and storage, and educating your customers with clear care guidelines.

By taking this proactive and layered approach, you protect your brand's reputation for quality, reduce product returns, and build greater customer loyalty. A buckle that stays beautiful is a product that gets worn, appreciated, and recommended.

If you are looking for a manufacturing partner who understands the importance of these details and has the expertise to execute high-quality, tarnish-resistant metal finishes for your belt line or other accessories, we are here to help. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can build durability and lasting beauty into your next collection.