You're in the middle of a busy season, planning your inventory for the upcoming spring collection. Everything seems to be on track. But then you hear a term that sends a wave of panic through new importers: "Chinese New Year." You're worried about your production coming to a screeching halt. Will your orders be delayed for weeks, or even months? Will you miss your window for new spring arrivals, leaving your shelves empty and your customers disappointed? This uncertainty can be incredibly stressful.

To prepare for Chinese New Year (CNY), a fashion accessories business must finalize all orders with their Chinese supplier by early December at the latest. You need to account for a production shutdown of at least three to four weeks and build a significant inventory buffer to cover this period, while also planning for potential quality control and shipping delays immediately before and after the holiday.

As the owner of Shanghai Fumao Clothing, a factory that has navigated this cycle for decades, I can tell you that Chinese New Year is not a problem to be feared, but a reality to be planned for. It's the most important cultural event in China, a time for family, rest, and celebration. For our partners, the key to a stress-free CNY is simple: communication and advance planning. Let's break down exactly what you need to do, and when, to ensure your business runs smoothly through the holiday period.

Why is Chinese New Year Such a Big Deal for Production?

You understand it's a holiday, but you're struggling to grasp the sheer scale of it. You might think it's just a day or two off, like Christmas. You're worried that you're overreacting, or worse, under-reacting. The fear is that by not understanding the true impact of CNY, you'll make a critical planning mistake that will disrupt your entire supply chain for the first quarter of the year.

The reality is that Chinese New Year is the largest annual human migration on Earth. It's not a long weekend; it's a nationwide shutdown that lasts for weeks. Virtually every factory, supplier, and logistics company closes. Millions of workers travel from industrial cities back to their hometowns, and many do not return to their jobs until weeks after the official holiday ends. This creates a massive, unavoidable bottleneck in production and shipping.

For my team and I, this is an annual rhythm. We work incredibly hard in the months leading up to the holiday to ensure all our clients' orders are completed and shipped. We know that once the shutdown begins, nothing moves. Understanding this "Great Halt" is the first and most critical step in your planning. It’s not a matter of asking your supplier to work through it; it’s a matter of working around it. This reality directly impacts your production and ordering timeline.

How long does the shutdown actually last?

While the official public holiday is about seven days, the disruption is much longer. Most factories begin to wind down operations one to two weeks before the New Year's Eve date. They will stop accepting new, complex orders even earlier. After the official holiday, it can take another one to two weeks for the factory to ramp back up to full capacity. This is because not all workers return at the same time, and some may not return at all, requiring factories to hire and train new staff. In total, you should plan for a minimum of three to four weeks of significant disruption. You can check the exact dates for the upcoming CNY on sites like TimeAndDate.com.

What is the "post-CNY" employee turnover?

This is a hidden challenge that many importers don't anticipate. The Chinese New Year period is traditionally a time when workers decide to make life changes. Many choose to stay in their hometowns or seek employment closer to home after the holiday. This can lead to a significant employee turnover rate at factories. For manufacturers, this means a period of hiring and training new staff right after they reopen. For you, the buyer, this can mean a potential dip in quality or efficiency as new, inexperienced workers get up to speed. This is a key reason why it's crucial to have your most important orders completed before CNY. For more on labor trends in China, you can refer to resources from organizations like the International Labour Organization.

What is the Ultimate CNY Ordering Timeline?

You know you need to order early, but how early is early enough? You're looking at the calendar, trying to work backward, but you're unsure of all the variables. You're worried that if you miscalculate, your order will get stuck in the pre-CNY chaos or, even worse, be pushed to the back of the line after the holiday.

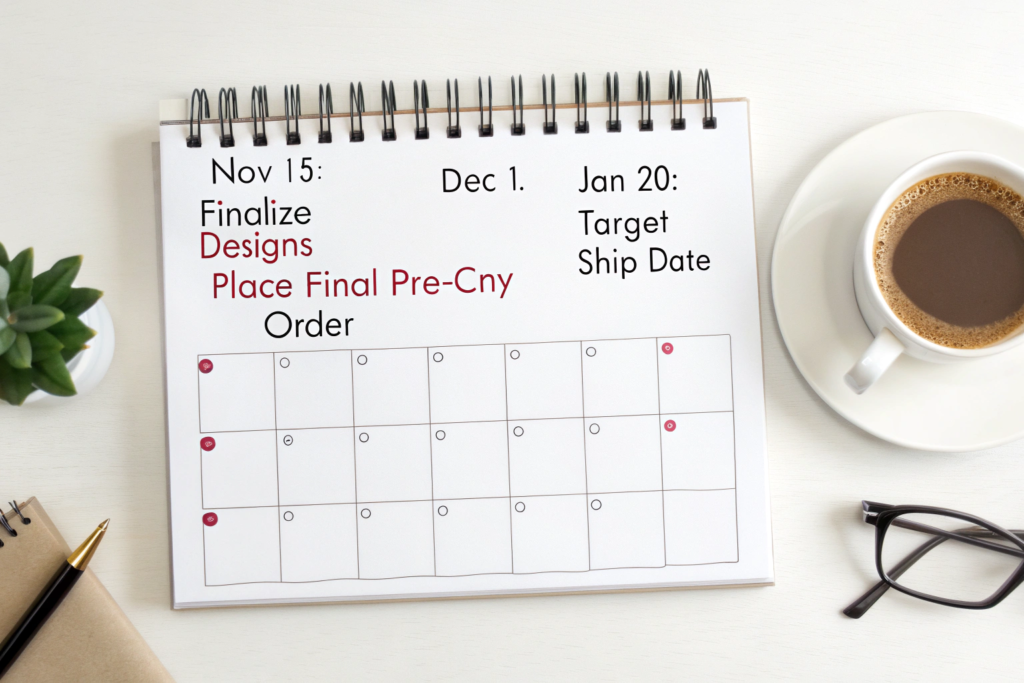

Here is the simple, safe timeline we advise all our clients to follow. To be secure, you must place your final, confirmed order for pre-CNY shipment no later than the first week of December. This gives the factory enough time to source raw materials (which also become scarce), schedule production, and manage quality control without rushing. Any orders placed after this date run a high risk of being delayed until after the holiday.

At our factory, the months of October and November are our busiest of the year. We are in constant communication with our clients, finalizing designs and confirming quantities. Our project managers at AceAccessory work tirelessly to create a production schedule that ensures every partner's order is on a container before the ports grind to a halt. Think of early December as the absolute final boarding call for pre-CNY production. Following this timeline is the most important step you can take, and it directly impacts your ability to manage inventory and cash flow.

What should I do in October and November?

October and November are your critical planning months. This is the time to finalize your product designs and assortment for your Spring collection. Communicate with your supplier's project manager to get accurate quotes and production lead times. Approve your pre-production samples during this period. Your goal is to have everything 100% confirmed so that when December 1st arrives, you are not negotiating details; you are simply submitting a purchase order. For fashion businesses, this aligns well with trend forecasting from services like WGSN, which release their reports months in advance.

What happens if I place an order in January?

If you place a new order in January, you must assume it will not be produced until after the CNY shutdown. A factory may accept the order to be polite, but they will not have the capacity to start it. It will be placed in the queue for when they reopen in late February or early March. This means you likely won't receive your goods until April. This can be a disaster for seasonal products. It's far better to have a realistic understanding of the timeline than to operate on wishful thinking.

How Should I Manage Inventory and Cash Flow?

You understand the timeline, which means you need to place a much larger order than usual in December. This immediately raises two concerns: where will you store all that extra inventory, and how will you manage the cash flow hit of paying for it so far in advance? You're worried about tying up too much capital and straining your storage capacity.

This is the strategic challenge of CNY. You must treat it as a predictable supply chain disruption and build a buffer. You need to order enough inventory in your pre-CNY shipment to last you through your normal selling season until your first post-CNY shipment can arrive (realistically in April). This means ordering for January, February, and March all at once. Yes, this requires a larger upfront investment. It's crucial to plan your finances accordingly, perhaps by securing a line of credit or adjusting your budget in the preceding months.

We work with our clients on this. Sometimes, we can arrange for partial shipments in December and January to help spread out the delivery. However, the production itself must be completed before the holiday. For our partners, the peace of mind that comes from having enough stock on hand to meet customer demand far outweighs the short-term challenges of storage and cash flow. Running out of your best-sellers in February with no chance of a restock is a far bigger business risk. This inventory strategy is directly linked to the quality control risks.

How much extra inventory should I order?

Look at your sales data from the previous year for the first quarter (January-March). Use this as a baseline. If you are a growing business, add a percentage for growth (e.g., 20%). This total is the approximate amount of inventory you need to have on hand before the CNY shutdown begins. It's always better to be slightly overstocked than to be completely sold out with no replenishment in sight. Inventory management software like Cin7 can help you forecast these numbers more accurately.

How can I manage the financial strain?

Plan ahead. Start conserving cash in the third and fourth quarters in anticipation of this large pre-CNY purchase order. Speak with your bank about a short-term business line of credit to help bridge the gap. Be transparent with your supplier; some may be willing to offer slightly more flexible payment terms (e.g., 40% down and 60% on shipment, instead of 30/70) if you have a long-standing relationship. The key is to not let this large payment be a surprise. Treat it as a predictable, annual business expense and budget for it accordingly. Financial planning resources from institutions like the U.S. Small Business Administration (SBA) can provide valuable frameworks.

What Are the Quality and Shipping Risks?

You've placed your order on time. You feel relieved. But then a new worry emerges. With every factory rushing to finish orders, will quality standards slip? Will your products be rushed through production? And even if the products are great, will your container get "rolled" (bumped) to a later vessel at the congested port?

These are very real risks. The weeks leading up to CNY are frantic. Factories are running at over 100% capacity, and workers are tired. This is when mistakes can happen. Similarly, ports become incredibly congested, and shipping lines often overbook their vessels. Your container getting rolled can mean a delay of a week or more, which could be the difference between shipping before or after CNY.

This is where having a strong relationship with a top-tier manufacturer like Shanghai Fumao Clothing makes a world of difference. A good partner will not sacrifice quality for speed. Our internal QC teams are on high alert during this period. Furthermore, we have long-standing relationships with freight forwarders, which gives us priority booking and dramatically reduces the risk of our clients' containers being rolled. We manage this chaos so you don't have to. It's our job to navigate the storm and get your products safely on the water. This is the final, critical piece of the CNY timeline.

Should I schedule a pre-shipment inspection?

Yes, 100%. During the pre-CNY rush, a third-party pre-shipment inspection is more important than ever. It is your last line of defense against potential quality fade. Schedule this inspection well in advance, as inspectors also get fully booked. Inform your supplier of the inspection date when you place your order. A good factory will welcome this as part of the process. Services like QIMA are experts in this field.

How can I minimize shipping risks?

Book your freight as early as possible. As soon as your supplier gives you a projected production completion date, get your freight forwarder to book space on a vessel. Be prepared to potentially pay a premium for shipping during this peak season to secure a spot. Communicate constantly with your supplier and your forwarder. Ask for updates. A proactive approach can help you spot potential delays early and make contingency plans. Reputable freight forwarders like Flexport often provide excellent visibility and communication tools.

Conclusion

Preparing for Chinese New Year is a defining annual challenge for any business that manufactures in China. But with foresight and a strategic plan, it can be managed smoothly and without stress. It all comes down to respecting the timeline, communicating clearly with your partner, and planning your inventory and finances accordingly. By finalizing your orders by early December, building a three-month inventory buffer, and being vigilant about quality and shipping, you can turn a period of potential chaos into a well-deserved, quiet season for your supply chain.

At Shanghai Fumao Clothing, our goal is to make this process seamless for our partners. We pride ourselves on the proactive communication and expert planning that allow our clients to rest easy, knowing their inventory is safe and their business is secure through the holiday.

If you are looking for a manufacturing partner who can help you navigate the complexities of the global supply chain with confidence, I invite you to reach out. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com to plan for the year ahead.