As a business owner, you know that every single component of your product reflects on your brand. You've sourced high-quality leather for your belts, but now you're stuck on the clasp. You worry that choosing the wrong one could undermine the entire product. A cheap, flimsy buckle can break, tarnish, or just feel disappointing to the customer, leading to returns and damaging the premium image you've worked so hard to build.

To select the best clasp for a quality belt, you must focus on two key factors: the material and the mechanism. Solid brass or stainless steel offer the best durability and a premium feel, while the clasp style—such as a frame-style, plate, or box buckle—should be chosen based on the belt's intended use, whether for formal, casual, or workwear.

I've spent years in the fashion accessory business, and I can tell you that the buckle is the heart of the belt. It’s the primary point of interaction for the customer and a major indicator of overall quality. At my company, Shanghai Fumao Clothing, we guide our clients through this selection process every day. Choosing the right clasp isn't just about aesthetics; it's about ensuring longevity, functionality, and customer satisfaction. Let's explore the critical elements you need to consider to make the perfect choice for your brand.

What Are the Best Materials for Belt Clasps?

You're looking at supplier catalogs filled with countless buckle options, and they all start to look the same. You see terms like "zinc alloy," "brass," and "stainless steel," but you're not sure which one truly signifies quality. The fear is choosing a material that looks good initially but quickly tarnishes, corrodes, or even breaks, leading to unhappy customers and a damaged brand reputation.

The solution is to understand the core properties of each metal. For a truly high-quality belt, your best choices are solid brass and stainless steel. These materials are known for their strength, corrosion resistance, and the substantial, premium feel they provide. While other materials like zinc alloy have their place, they don't offer the same level of durability and longevity required for a top-tier product.

Making the right material choice is fundamental. It's a decision that directly impacts the customer's long-term experience with your product. A solid brass buckle will develop a unique patina over time, adding character, while a stainless steel one will maintain its sleek look indefinitely. Both are excellent stories to tell your customers. This focus on durable, high-quality components is a principle we live by. When you're ready to think about the buckle's design, you'll also want to consider which clasp style fits your belt.

Why is solid brass a premium choice?

Solid brass is a classic, top-tier material for belt buckles due to its exceptional durability and aesthetic appeal. It is an alloy of copper and zinc, making it highly resistant to corrosion—it won't rust. Over time, solid brass develops a natural patina, a subtle darkening and change in luster that is highly prized by consumers who appreciate vintage or heritage aesthetics. This aging process means each buckle becomes unique to its owner. It has a satisfying weight that conveys quality the moment a customer picks it up. While it is more expensive than other materials, its longevity and timeless appeal make it a worthwhile investment for any brand positioning itself as high-quality. For more on metal properties, you can visit a materials science resource like the American Society for Metals (ASM International).

What are the benefits of stainless steel?

Stainless steel is another excellent choice for premium belt clasps, known for its incredible strength and modern, clean look. Its primary advantage is its superior resistance to rust, scratches, and tarnishing, thanks to its chromium content. This means a stainless steel buckle will look brand new for years, even with daily wear. It is also hypoallergenic, making it a great option for customers with sensitive skin who might react to brass or other alloys. While it doesn't develop a patina like brass, its sleek, polished, or brushed finish is perfect for modern, minimalist, or formal belt designs. Its durability is legendary, which is why it's used in everything from surgical instruments to high-end watches from brands like Rolex.

Which Clasp Style Fits Your Belt?

You've chosen the perfect, durable material for your clasp, but now you're faced with a dizzying array of styles: frame, plate, box, D-ring. You're worried that picking a style that doesn't match your belt's design or your target customer's needs will result in a product that just doesn't sell. A formal buckle on a casual belt, or a cumbersome one on a sleek design, can create a jarring look and poor user experience.

The key is to match the clasp's mechanism and aesthetic to the belt's purpose. A Frame-Style Buckle is a timeless choice for classic leather dress belts. A Plate-Style Buckle is often more decorative and works well for statement or Western-style belts. A Box-Frame Buckle is a simple, functional choice common on casual, webbed fabric belts. By aligning the style with the function, you create a cohesive and desirable product.

At our factory, we often act as consultants for our clients, helping them pair the right buckle style with their belt strap design. A client might come to us with a beautiful strap design, and our project managers will suggest a range of clasp styles that would complement it perfectly, considering both form and function. This collaborative process ensures the final product is not only well-made but also well-designed. Understanding the style is just as important as understanding the finishing and plating options.

When should I use a frame-style buckle?

The frame-style buckle is the most traditional and common type of belt clasp. It consists of a frame, a prong (or tongue) that goes through a hole in the belt strap, and a single loop to hold the belt tip. This classic design is the go-to choice for formal and business-casual belts. Its simple, secure mechanism is reliable and familiar to all users. For a high-quality dress belt, a slim, polished frame-style buckle made of solid brass or stainless steel is the industry standard. Its understated elegance complements fine leather and tailored clothing without drawing too much attention. You can see this style ubiquitously used by high-end fashion houses like Gucci in their classic leather belt collections.

Are plate-style buckles a good choice?

Plate-style buckles are generally more decorative and serve as a statement piece. They consist of a flat plate, often with intricate designs, logos, or embellishments, and a hook on the back that catches a hole in the belt strap. These are commonly associated with Western wear (think large, ornate silver buckles) but are also used for branded fashion belts where the logo is the main feature. While they can be very stylish, their suitability depends entirely on your target market. They are best for casual or fashion-forward belts rather than formal attire. When choosing a plate buckle, ensure the hook mechanism is sturdy and well-cast to prevent it from bending or breaking with use. For inspiration on decorative metalwork, you can explore museum collections like those at the Victoria and Albert Museum.

What Finishing and Plating Options Are Available?

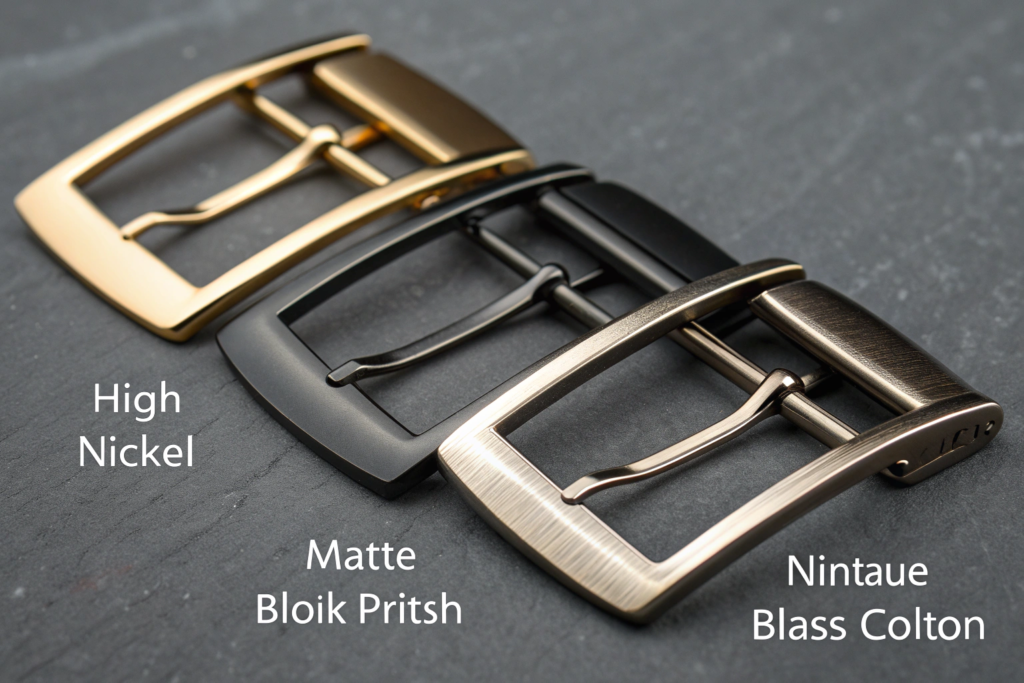

You've settled on a material and style, but now you're presented with a list of finishes: "antique brass," "brushed nickel," "matte black PVD." You're concerned that a poor finish will cheapen the look of your high-quality buckle. The risk is that the plating could chip, flake, or wear off quickly, revealing the base metal underneath and ruining the customer's perception of your product as a premium item.

Your focus should be on choosing a durable finish that complements the belt's overall design. For solid brass or stainless steel, you may not need plating at all, as the raw material is beautiful and durable on its own. If you do opt for a finish, choose high-quality plating methods like PVD (Physical Vapor Deposition) for superior durability. This method creates a very thin, hard, and corrosion-resistant layer that is far more durable than traditional electroplating.

The finish is the final touch that can elevate a good buckle to a great one. It’s a detail that discerning customers will notice. At Shanghai Fumao Clothing, we offer a wide range of finishing options and always provide clear guidance on which methods offer the best longevity for the price. We want your product to look as good on day 100 as it did on day one. A great finish is a silent testament to your brand's quality, and it's a detail that's closely tied to the overall quality control process.

What is PVD coating and why is it superior?

PVD (Physical Vapor Deposition) coating is a modern finishing process conducted in a high-vacuum environment. It involves vaporizing a solid material (like titanium nitride) and depositing it as a thin film on the surface of the buckle. This process creates a finish that is extremely hard, durable, and resistant to scratches, tarnishing, and corrosion. It is significantly more durable than traditional electroplating, which can be prone to chipping or flaking. PVD is often used in high-end industries where durability is critical, such as for luxury watches and medical devices. While it is a more expensive finishing option, its longevity makes it an excellent choice for a premium belt meant to last for years. You can find technical details on this process from scientific sources like ScienceDirect.

How do I choose between polished, brushed, or antique finishes?

The choice of finish texture depends on the desired aesthetic of your belt. A polished finish offers a shiny, mirror-like surface that is ideal for formal or dress belts, conveying a sense of luxury and elegance. A brushed finish has a subtle, non-reflective texture created by fine parallel lines. It is excellent at hiding fingerprints and minor scratches, making it a practical and popular choice for everyday casual and workwear belts. An antique finish (e.g., antique brass, antique silver) is created by chemically darkening the buckle and then relieving the high points to simulate natural aging. This finish is perfect for vintage-inspired, rustic, or Western-style belts, adding a sense of character and history right out of the box. For examples of these finishes in practice, browse the collections of established accessory brands like Fossil.

How Can I Ensure Consistent Quality?

You've specified the exact material, style, and finish for your belt clasp. But a persistent worry remains: how do you ensure that the 1,000th buckle is just as perfect as the first sample you approved? The fear of inconsistency in a bulk order—variations in color, faulty mechanisms, or rough edges—is a major concern for any buyer. These defects can lead to a significant portion of your inventory being unsellable.

The answer lies in establishing a partnership with a manufacturer that has a transparent and robust quality control (QC) process. A reliable supplier should be able to provide you with their QC checklist, allow for third-party inspections, and communicate proactively throughout the production run. This isn't about micromanaging; it's about building a system of checks and balances to guarantee consistency.

This is a non-negotiable for us. As a manufacturer for major brands, we at AceAccessory have built our reputation on consistency. Our QC team inspects everything from the raw material to the final packaged product. We perform stress tests on mechanisms, check plating thickness, and ensure every edge is smoothly finished. We believe that quality is not just a department; it's a mindset that permeates our entire operation, ensuring that every piece we ship meets the high standards our clients expect. This commitment to quality is just as important as choosing the right clasp material in the first place.

What should I ask a supplier about their QC process?

When vetting a supplier, be direct and specific with your questions. Ask them: "Can you share your documented quality control procedures for belt buckles?" A good supplier will have a standard operating procedure (SOP). Inquire about their inspection points: Do they inspect raw materials upon arrival? Do they perform in-process inspections during casting and finishing? What is their final inspection process before packing? Ask about their defect classification system (e.g., AQL - Acceptable Quality Limit). Also, ask if they are open to a third-party inspection service, like QIMA, coming in to verify the order before shipment. A transparent and confident supplier will welcome these questions.

How do I test samples for mechanical durability?

When you receive pre-production samples, you need to test them rigorously. For a belt buckle, this means focusing on the mechanical parts. Open and close the mechanism repeatedly—at least 50-100 times—to check for smoothness and signs of wear or stress. For a frame-style buckle, check the prong's hinge for any looseness. Put the buckle on a belt strap and pull on it firmly to simulate the stress of daily wear. Does the prong bend? Does the frame warp? For plated buckles, try a simple adhesion test, like the cross-hatch test, where you score the surface and apply tape to see if any of the plating flakes off. These simple, practical tests can reveal potential weaknesses that might not be visible to the naked eye and are similar to methods used by consumer advocacy groups to test product durability.

Conclusion

Selecting the best clasp for a quality belt is a detailed process, but it's one that pays huge dividends in customer satisfaction and brand reputation. It begins with choosing a superior material like solid brass or stainless steel that promises longevity. It continues with matching the clasp style—be it frame, plate, or box—to the belt's intended purpose. Finally, it's about selecting a durable finish and, most importantly, partnering with a manufacturer who guarantees unwavering quality through a transparent and rigorous QC process. These elements combined will ensure the buckle is not a weak link, but a highlight of your product.

At Shanghai Fumao Clothing, we specialize in guiding our clients through every step of this journey. Our experienced team understands the nuances of creating high-quality fashion accessories, from material science to precision manufacturing. We are committed to being a reliable partner who can help you build a product line that stands for quality and style.

If you're ready to create exceptional belts with clasps that truly perform, I invite you to connect with us. Please reach out to our Business Director, Elaine, at her email: elaine@fumaoclothing.com to discuss your project.