A Purchase Order (PO) is much more than just a price quote or a simple request to buy. In the world of fashion accessory sourcing, it is the foundational legal document that turns a conversation into a clear, binding contract. For buyers like you, a well-structured PO protects your investment by locking in specifications, price, and terms. For manufacturers like us at AceAccessory, it is the precise blueprint we follow to ensure we deliver exactly what you expect. Getting the PO right from the start is the single most effective way to prevent costly and time-consuming misunderstandings.

The basic elements of a fashion accessories purchase order are comprehensive product descriptions, unambiguous quantity and pricing terms, clear quality and compliance standards, and detailed logistics and payment schedules. A complete PO functions as an all-in-one instruction manual, quality control checklist, and commercial contract for your order. Think of it as the rulebook for your entire production run—every potential question should have its answer within this document.

Let's break down the essential components that should be on every PO you issue to ensure a smooth, professional, and dispute-free manufacturing process.

Why is Detailed Product Specification the Most Critical Section?

The product specification section is the heart of your PO. Vague descriptions like "women's scarf" are invitations for error. This section must leave no room for interpretation, serving as the absolute authority on what the finished product should be. Ambiguity here leads to wrong shipments, rejection of goods, and strained relationships.

This section must include a technical pack ("tech pack") reference or incorporate all its details: style name/number, detailed SKUs, and precise descriptions of materials, dimensions, colors, and trim. For example, a PO for a "Knit Beanie" should not just state "acrylic yarn." It must specify: "100% Acrylic, 2-ply twisted yarn, 300gsm weight." Every component, down to the label and care tag, needs to be defined.

What Specific Details Must Be Included for Each Item?

Each line item in your PO should be a mini-specification sheet. Crucial details include:

- Style Name/Number & SKU: Your unique internal identifier.

- Material Breakdown: Exact fiber content and composition (e.g., "Shell: 65% Polyester, 35% Cotton; Lining: 100% Bemberg Cupro").

- Color Names and Codes: Use both verbal descriptions and universal codes like Pantone (PMS) or lab-dip reference numbers approved during development. For example, "Scarf - Color: Crimson Red (Pantone 19-1763 TPX)."

- Dimensions/Size: In both metric and imperial units if needed (e.g., "Scarf Dimension: 180cm L x 70cm W").

- Packaging Details: How each unit is packaged (polybag, hangtag, card) and how units are packed into the master carton (inner/outer box dimensions, quantity per carton).

How Do You Reference Quality Standards and Samples?

Never assume quality levels. The PO must explicitly state the agreed-upon quality benchmarks. This is done by:

- Referencing the Approved Sample: Clearly note, "Production must match in all aspects the Pre-Production Sample (PPS) approved on [Date], with sample ID #XYZ."

- Stating the Inspection Standard: Specify the Acceptable Quality Level (AQL) to be used for final inspection (e.g., "Final Random Inspection to be conducted per AQL General Level II, with Major defects at 1.5 and Minor defects at 4.0.").

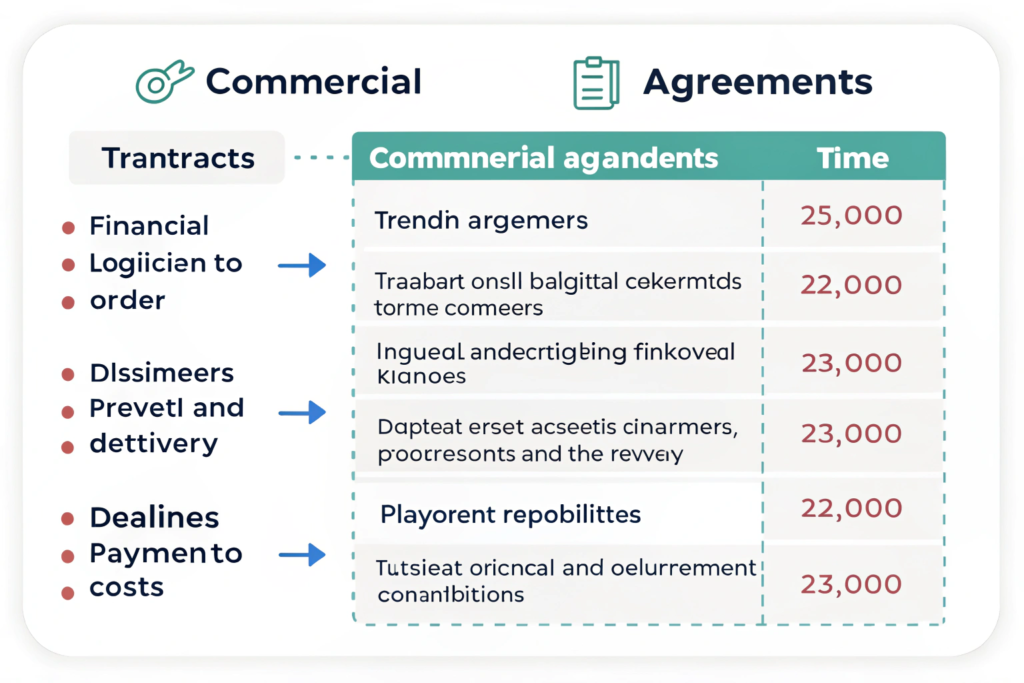

What Are the Non-Negotiable Commercial Terms?

The commercial terms translate your agreement into numbers and deadlines. This section covers the financial and logistical framework of the order. Clarity here prevents disputes about cost, delivery windows, and payment liabilities.

The commercial terms must precisely define the unit price, total order value, delivery date, shipping method, and the agreed-upon Incoterms® 2020 rule. These terms collectively answer the critical questions of "how much," "when," and "who is responsible for what" during shipment.

How Should Pricing, Quantities, and Delivery Be Structured?

A clear table is the best way to present this information. It should list each item, its SKU, color, unit price in the agreed currency (e.g., USD, EUR), order quantity, and extended line total. Below the table, state the Total Order Value clearly.

The Delivery Date should be specified as a clear date (e.g., "October 25, 2025") or a week (e.g., "Week 43, 2025"). It's also wise to define whether this is the "Date Ready for Shipment" at the factory or the "Estimated Time of Arrival (ETA)" at your port. The chosen Incoterms® 2020 rule (e.g., FOB Shanghai, EXW Factory, CIF Los Angeles) is non-negotiable and must be stated, as it dictates cost and risk transfer.

What Payment Terms are Standard and Secure?

Clearly outline the payment method (e.g., Telegraphic Transfer/TT, Letter of Credit/LC) and the payment schedule. A common and balanced schedule for new partners might be: 30% deposit with order confirmation, 70% balance against copy of Bill of Lading. For established partnerships, terms might be net 30 days after BL date. Always include your company's official remittance details and require the same from the supplier.

Why Do Compliance, Logistics, and Shipping Instructions Matter?

This section addresses the regulatory and physical journey of your goods. Overlooking it can result in customs delays, confiscation of goods, or unexpected charges. It ensures your products can legally enter your target market and arrive at the correct destination in good condition.

This section must include all necessary compliance documentation, complete shipping marks and labels for cartons, and the final destination/consignee details. It's about ensuring a smooth transition from the factory floor to your warehouse.

What Compliance Documents are Required?

List every document you require from the supplier. Standard documents include:

- Commercial Invoice

- Packing List

- Certificate of Origin (often required for tariff purposes)

- Bill of Lading or Air Waybill

For certain materials or markets, you may also need: - Test Reports (e.g., for flammability, lead content, as required by the Consumer Product Safety Commission (CPSC) for the US market).

- Material Safety Data Sheets (MSDS)

- Phytosanitary Certificate (for natural materials like wood or straw).

How to Avoid Confusion in Shipping and Labeling?

Provide explicit shipping marks for the outer cartons. This typically includes your company name, PO number, style number, color, carton quantity, and carton number (e.g., "1 of 20"). Also, specify any mandatory labeling requirements for the products themselves, such as content labels, care labels, country-of-origin labels ("Made in China"), and barcode or UPC stickers.

How Do You Formalize the Agreement and Manage Changes?

The final section of the PO formalizes the agreement and establishes a process for any future changes. It turns the document from a list of requests into an executed contract.

This is done by including authorized signatures from both buyer and seller, and a clear clause outlining the procedure for any amendments (via a formal "Change Order"). This protects both parties from unauthorized changes to the order's scope, timeline, or cost.

What is the Purpose of Signatures and a Change Order Clause?

The signature blocks for both "Buyer" and "Seller" with printed names, titles, and dates make the PO a legally binding purchase agreement upon the supplier's acceptance (usually by counter-signature).

The Change Order clause is a critical governance tool. It should state that any change to the original PO—be it in quantity, design, delivery date, or price—must be requested in writing and agreed upon by both parties via a formal Change Order document. This prevents informal, last-minute requests from derailing production and ensures all cost and timeline implications are documented and approved before work proceeds.

Sample procurement procedure for fashion accessory orders?

Sample procurement procedure for fashion accessory orders involves a structured sequence of steps to ensure timely, cost-effective, and quality-compliant acquisition of products. The process typically begins with requirement definition, where the buyer identifies specific fashion accessory needs, such as types (e.g., necklaces, bracelets, earrings, hairpins), materials (e.g., gold-plated, silver, beads, leather, fabric), styles (e.g., minimalist, bohemian, luxury), quantities, and target price ranges. This phase may involve market research to assess trends, competitor offerings, and customer preferences, ensuring the ordered items align with current fashion demands. Next, supplier identification and evaluation occurs: potential suppliers are sourced through industry directories, trade shows, or referrals.

Conclusion

A comprehensive Purchase Order is your primary tool for risk management in fashion accessory sourcing. It transforms verbal agreements into actionable, accountable instructions. By meticulously detailing product specifications, commercial terms, compliance needs, and logistics, you create a transparent framework for a successful partnership. A strong PO sets the stage for on-time delivery of products that match your quality and design vision, ultimately protecting your brand and your bottom line.

If you are looking for a manufacturing partner who values clarity, precision, and professionalism from the first PO to the final shipment, AceAccessory is here to help. Our experienced project managers are adept at working with detailed POs to ensure flawless execution. For your next accessory order, contact our Business Director, Elaine, at elaine@fumaoclothing.com to begin a partnership built on clear communication and outstanding results.