When you’re branding apparel or accessories, your choice of decoration method makes a powerful statement. It affects the look, feel, durability, and cost of your final product. Two of the most popular methods—embroidery and screen printing—often leave buyers wondering which is the “best” choice. The truth is, there is no single best option, only the best option for your specific design, product, and budget.

The core difference lies in the application: embroidery involves stitching thread directly onto the fabric to create a textured, raised design, while screen printing uses ink pressed through a mesh stencil to create a flat, graphic layer on the fabric's surface. This fundamental distinction drives all other differences in aesthetics, durability, cost, and suitability.

This guide will break down the key factors to help you confidently choose the right technique for your next order.

How Do the Processes and Aesthetics Fundamentally Differ?

Understanding how each technique is applied is key to understanding why they look and feel so different. The process dictates the final result, from the texture you feel—whether it's the smooth, polished sheen of a meticulously sanded surface or the rough, tactile grain of a hand-carved wood—to the visual impact from a distance, where subtle variations in color depth, light reflection, and pattern arrangement create distinct aesthetic impressions that draw the eye and evoke different emotions.

What is the Embroidery Process and Its Classic Look?

Embroidery is an additive process that builds a design with thread. A digital design file is programmed into an embroidery machine, which uses needles to stitch hundreds to thousands of individual threads onto the garment.

- The Result: This creates a textured, three-dimensional and tactile finish. The design is physically part of the fabric, giving it a premium, durable, and often traditional or corporate feel. It excels with logos, lettering, and designs with distinct, solid areas of color. Fine detail, like very small text or subtle gradients, can be challenging to replicate perfectly.

What is the Screen Printing Process and Its Graphic Impact?

Screen printing is a layering process. A separate stencil (or "screen") is created for each color in the design. Ink is pushed through the fine mesh of the screen onto the fabric below.

- The Result: This creates a smooth, flat layer of ink on the fabric. It allows for vibrant, opaque colors and is excellent for large, bold graphics, photographic images, gradients, and designs with many colors. The feel is integrated with the fabric's surface rather than raised from it.

Which Method is More Durable and Cost-Effective?

Durability and cost are often the deciding factors for buyers, as these elements directly impact long-term satisfaction and value. Each method has a different value proposition over the lifespan of the garment, with some prioritizing robust construction that withstands frequent wear and tear, while others offer lower upfront costs but may require more frequent replacement.

For instance, garments made with reinforced stitching, high-quality fabrics like organic cotton or synthetic blends designed for resilience, and durable zippers or buttons tend to have higher initial prices but can last for years, reducing the need for repeated purchases.

How Does Long-Term Durability Compare?

This is a key differentiator tied directly to the technique.

- Embroidery: The stitched threads are extremely durable. They can withstand repeated washing, abrasion, and exposure to the elements without cracking or peeling. The design becomes a permanent part of the fabric. This makes it the preferred choice for workwear, uniforms, and high-use items like caps and bags where longevity is critical.

- Screen Printing: The durability of screen printing depends heavily on the ink quality and curing process. While modern plastisol and discharge inks are very durable, they can eventually crack or fade with extensive washing and wear, especially if printed on a fabric that stretches significantly. It is perfectly durable for most casual apparel but may not last as long as embroidery under harsh conditions.

How Do Setup Costs and Pricing Structures Differ?

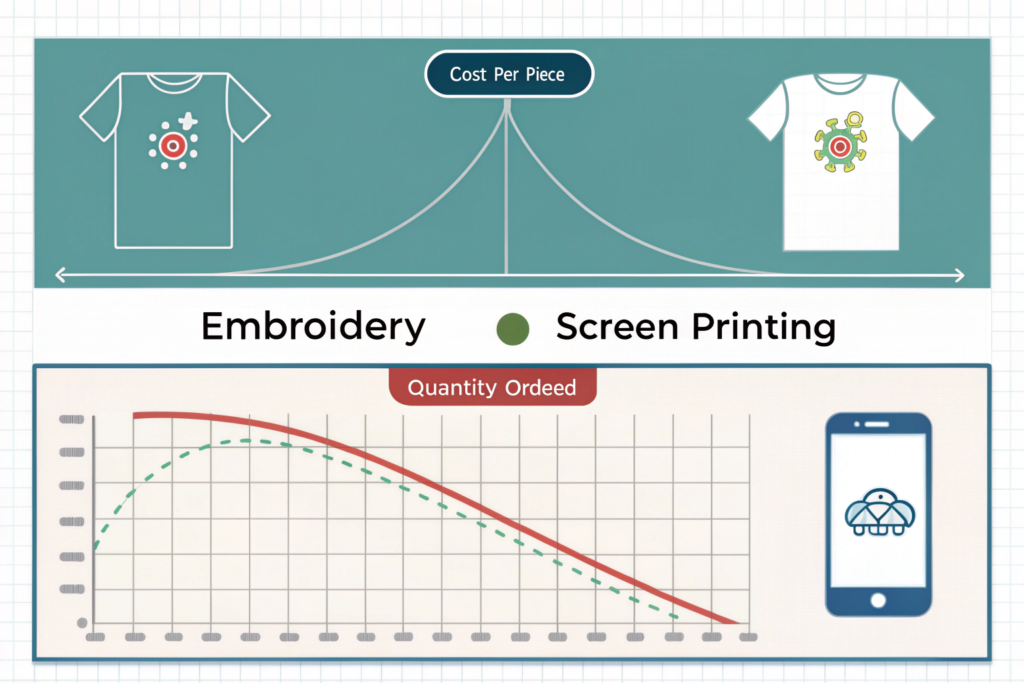

The cost dynamics are opposite for small vs. large orders.

- Embroidery: Has higher setup costs due to the need to digitize the design and set up the machine for each item location. However, the per-unit cost remains relatively consistent. This makes embroidery more economical for small to medium runs (e.g., 12-100 pieces) where the setup cost is amortized over fewer units.

- Screen Printing: Has lower initial setup costs for creating screens, but the per-unit cost decreases significantly with higher quantities due to the efficiency of the process. It becomes far more cost-effective for large bulk orders (e.g., 50+ pieces for a simple design, 100+ for complex ones).

What Are the Key Design and Application Limitations?

Every technique, whether it be a specialized method in engineering, a creative process in art, or a scientific approach in research, possesses inherent strengths that make it effective in specific contexts, yet also carries distinct boundaries that define its scope and applicability.

Recognizing these limitations is just as crucial as understanding the advantages they offer; this balanced awareness serves as a critical safeguard against potential production issues, such as inefficiencies, errors, or delays, and helps prevent the emergence of unsatisfactory results that fall short of desired outcomes.

What Are the Design Limitations for Each Technique?

The level of detail and complexity your design requires will point you toward the right method.

- Embroidery Limitations: It is less suited for designs with very fine lines, small text (below 0.2 inches or 5mm), or subtle color gradients. Excessive detail can cause threads to bunch up, making the design look blurred. The number of colors is also more practically limited compared to screen printing, as each color requires the machine to stop and change threads.

- Screen Printing Limitations: While it handles gradients well, achieving a true photographic quality with millions of colors requires specialized simulated process printing, which is costly. Very intricate designs with halftones can also be challenging on certain fabrics. Registration issues can occur if screens are not aligned perfectly.

Which Fabrics and Products Are Best or Worst for Each?

The material you are decorating is a critical, often overlooked, factor.

- Embroidery Compatibility: Best on structured, stable, or heavyweight fabrics like canvas, denim, twill (for caps), polo pique, and fleece. It can add desirable structure. It is not ideal for very stretchy, lightweight, or delicate fabrics (like thin silks or high-stretch knits) as the tension of the stitches can cause puckering, distortion, or even damage the material.

- Screen Printing Compatibility: Most effective on smooth, woven, or knitted fabrics with a consistent surface, such as cotton t-shirts, hoodies, and tote bags. It can be challenging on highly textured fabrics (like terry cloth or some wools), non-porous materials (like leather or nylon without pretreatment), or items with seams and uneven surfaces that the screen cannot lay flat against.

How Do You Make the Final Decision for Your Project?

The final choice should be a strategic decision based on a clear evaluation of your project's specific needs, taking into account factors such as budget constraints, timeline requirements, target audience demographics, technical feasibility, and long-term scalability.

Use this step-by-step framework to guide your selection: begin by defining the core objectives of the project, then identify key success metrics that will determine if the chosen option meets those goals. Next, conduct a thorough analysis of available options, considering both quantitative data (such as cost breakdowns, resource allocation, and performance benchmarks) and qualitative factors (like user experience, brand alignment, and stakeholder feedback).

What Are the Three Critical Questions to Ask First?

Start by answering these foundational questions:

- What is the primary item being decorated? (e.g., Cap, T-shirt, Jacket, Bag)

- What is the core design like? (e.g., Simple 3-color logo, Full-color photograph, Text-based)

- What is the approximate order quantity? (e.g., 24 pieces, 500 pieces)

Your answers will immediately point you toward a likely candidate. For example, "50 cotton twill caps with a 2-color logo" strongly suggests embroidery.

When Should You Consider a Combination of Both Methods?

For complex projects, don't feel limited to one technique. A hybrid approach can yield outstanding results. A common and effective combination is using embroidery for a primary, durable logo (e.g., on the chest of a jacket) and screen printing for larger, more graphic elements (e.g., on the back). This leverages the strengths of each method on a single garment for maximum impact.

Why is a Professional Sample Crucial?

Before committing to a full production run, always request a physical sample from your manufacturer on the actual fabric. This is the only way to truly assess the color accuracy, hand feel, detail clarity, and overall quality. It allows you to make any necessary adjustments to the design or technique before incurring large costs.

Conclusion

Embroidery and screen printing are both powerful branding tools with distinct personalities. Embroidery delivers a textured, premium, and durable finish ideal for logos on structured garments, excelling in small to medium runs. Screen printing offers vibrant, flat graphics perfect for bold designs on soft knits, becoming highly cost-effective at large volumes.

Your choice ultimately depends on the trifecta of design complexity, product type, and order quantity. A corporate polo calls for embroidery; a band tour t-shirt demands screen printing.

For brands and buyers navigating this decision, working with a manufacturer that masters both techniques is crucial. At Shanghai Fumao Clothing, we provide expert guidance and production for both embroidery and screen printing, ensuring your vision is executed perfectly on any accessory or apparel item. To discuss the best decoration method for your next order, please contact our Business Director Elaine at: elaine@fumaoclothing.com.