As a manufacturer deeply embedded in global fashion supply chains, we've witnessed firsthand how sustainable fashion movements are fundamentally reshaping accessory sourcing practices. What began as a niche concern has evolved into a comprehensive transformation affecting every stage of the sourcing process, from material selection to final production.

Sustainable fashion movements are driving a paradigm shift in accessory sourcing toward transparent supply chains, eco-friendly materials, ethical production practices, and circular business models. This transformation impacts decision-making at every level, requiring manufacturers to adopt new verification systems, material innovations, and production methodologies that prioritize environmental and social responsibility alongside traditional factors like cost and quality.

Based on our experience supplying major European and American brands that are implementing ambitious sustainability agendas, here's our analysis of how these movements are reshaping accessory sourcing across the industry.

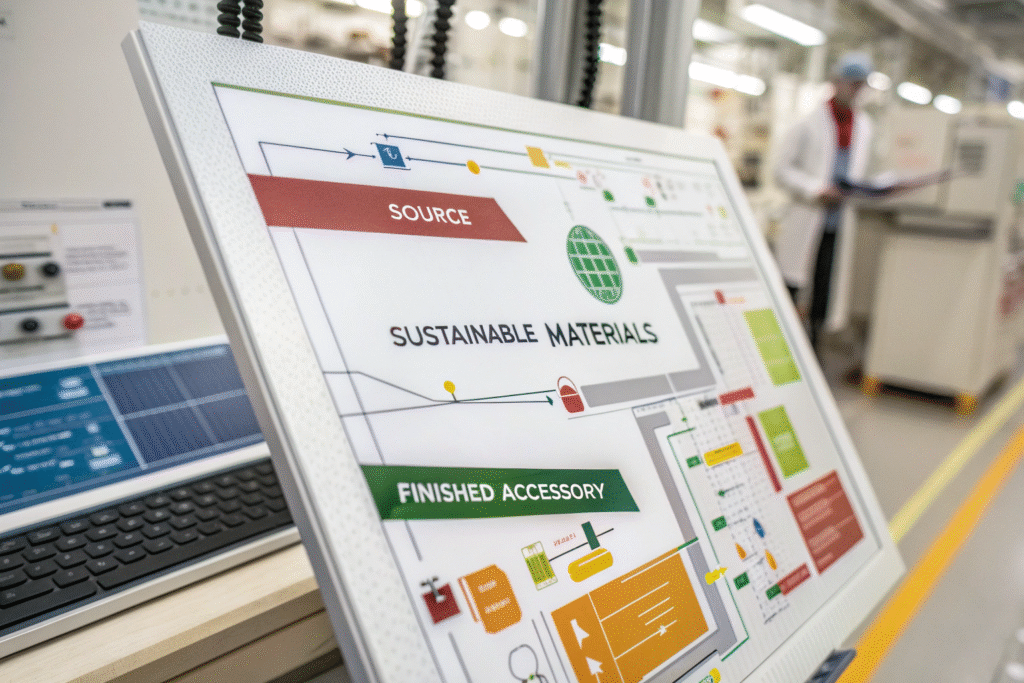

How Are Sustainable Materials Transforming Sourcing Decisions?

Sustainable material selection represents the most visible impact of environmental movements on accessory sourcing. The shift away from conventional materials toward eco-friendly alternatives requires comprehensive changes in supplier relationships, cost structures, and production processes.

The transition to sustainable materials involves complex considerations beyond simple substitution, affecting durability, aesthetics, production techniques, and ultimately consumer satisfaction with the final product.

What Eco-Friendly Material Options Are Available Today?

The range of eco-friendly material options for accessories has expanded dramatically, offering viable alternatives across product categories from handbags to hair accessories. These materials address various environmental concerns while meeting quality and aesthetic requirements.

Our material sourcing team has developed extensive expertise in sustainable material alternatives that now form the foundation of our eco-conscious collections. For leather alternatives, we offer materials derived from pineapple leaves, apple pomace, mushroom roots, and cactus, each with distinct aesthetic and performance characteristics. Recycled materials including polyester from plastic bottles, nylon from fishing nets, and metals from post-industrial waste provide circular solutions without compromising quality. Natural and biodegradable options like organic cotton, hemp, linen, and responsibly sourced wood offer renewable alternatives for various accessory components. Each material requires specialized handling and production adjustments that we've integrated into our manufacturing processes.

How Do Material Certifications Influence Sourcing Choices?

Material certifications have become critical decision-making tools in sustainable sourcing, providing verified standards that help brands navigate complex environmental and social claims. These certifications create frameworks for accountability throughout the supply chain.

We've implemented comprehensive certification management systems to meet our clients' requirements for verified sustainable materials. Global Organic Textile Standard certification ensures organic fiber integrity from harvesting through manufacturing. Leather Working Group ratings validate environmentally responsible tanning practices. Forest Stewardship Council certification tracks wood-based materials from sustainable sources. Recycled Claim Standard and Global Recycled Standard certifications verify recycled content claims. These certifications require meticulous documentation, chain of custody tracking, and regular audits that have become integral to our sourcing operations. For brands communicating their sustainability efforts to consumers, these third-party verifications provide essential credibility.

How Is Supply Chain Transparency Changing Sourcing Practices?

Supply chain transparency has evolved from a progressive ideal to a business imperative, driven by consumer demand for ethical production and regulatory requirements for disclosure. This transformation requires unprecedented visibility into multi-tier supply chains.

The push for transparency affects relationships with raw material suppliers, component manufacturers, and production partners, creating new standards for information sharing and accountability.

What Traceability Systems Are Emerging in Accessory Sourcing?

Advanced traceability systems are emerging to provide the detailed supply chain visibility required by sustainable sourcing initiatives. These technologies enable brands to track materials from origin to finished product, verifying environmental and social claims.

We've implemented several traceability technologies to meet our clients' transparency requirements. Blockchain-based systems create immutable records of material provenance and production milestones. RFID and QR codes enable item-level tracking throughout production and distribution. Digital product passports that consolidate sustainability information are becoming standard requirements from European brands. These systems require significant investment in data collection infrastructure and partner collaboration, but they provide the verification necessary to support sustainability claims and identify improvement opportunities within complex supply chains.

How Are Ethical Audits Influencing Supplier Selection?

Ethical auditing has become a standard component of supplier evaluation, with brands increasingly prioritizing social responsibility alongside traditional factors like cost, quality, and delivery. These assessments verify working conditions, fair compensation, and environmental management.

Our facility undergoes regular social compliance audits from third-party organizations and major brand representatives. These assessments evaluate working hours, wage practices, health and safety standards, environmental management, and ethical recruitment practices. The audit process has driven significant improvements in our operations, from enhanced safety protocols to better worker accommodation. For brands committed to ethical sourcing, these verifications provide assurance that their products are made under fair conditions. The consolidation of audit standards through initiatives like the Social & Labor Convergence Project reduces duplication while maintaining rigorous assessment criteria.

How Are Circular Economy Principles Reshaping Sourcing?

Circular economy principles are transforming sourcing from linear "take-make-waste" models to systems that maximize resource efficiency, extend product lifecycles, and regenerate natural systems. This shift requires rethinking material flows, business models, and product design.

The transition to circular sourcing models represents both a significant challenge and opportunity for accessory manufacturers, requiring innovation across product development, production, and end-of-life management.

What Role Does Recycled Content Play in Circular Sourcing?

Recycled content has become a cornerstone of circular sourcing strategies, reducing dependence on virgin materials while addressing waste management challenges. The quality and availability of recycled materials have improved significantly, making them viable for mainstream accessory production.

At shanghaifumaoclothing, we've developed specialized expertise in working with recycled material streams across different accessory categories. Post-consumer recycled polyester from plastic bottles offers performance characteristics equivalent to virgin materials for bags and accessories. Recycled metals from electronic waste provide beautiful finishing elements with compelling sustainability stories. Recycled cotton and wool from textile waste create unique aesthetic qualities while reducing resource consumption. Each material requires specific processing techniques that we've integrated into our production systems. The growing demand for recycled content is driving innovation in recycling technologies and material quality, expanding the possibilities for circular design.

How Are Take-Back Programs Influencing Product Design?

Take-back programs that reclaim products at end-of-life are influencing accessory design to facilitate disassembly, material separation, and recycling. Designing for circularity requires considering the entire product lifecycle during the initial development phase.

We've incorporated design for disassembly principles into our product development process to support our clients' take-back initiatives. This approach includes minimizing material types, using mechanical fasteners instead of chemical adhesives, standardizing components, and creating clear material identification systems. These design strategies enable efficient material recovery and recycling at product end-of-life, supporting closed-loop systems. The implementation of digital product passports that provide detailed material composition and disassembly instructions further enhances these circular systems. For brands implementing take-back programs, these design features are essential for maximizing material recovery value and minimizing waste.

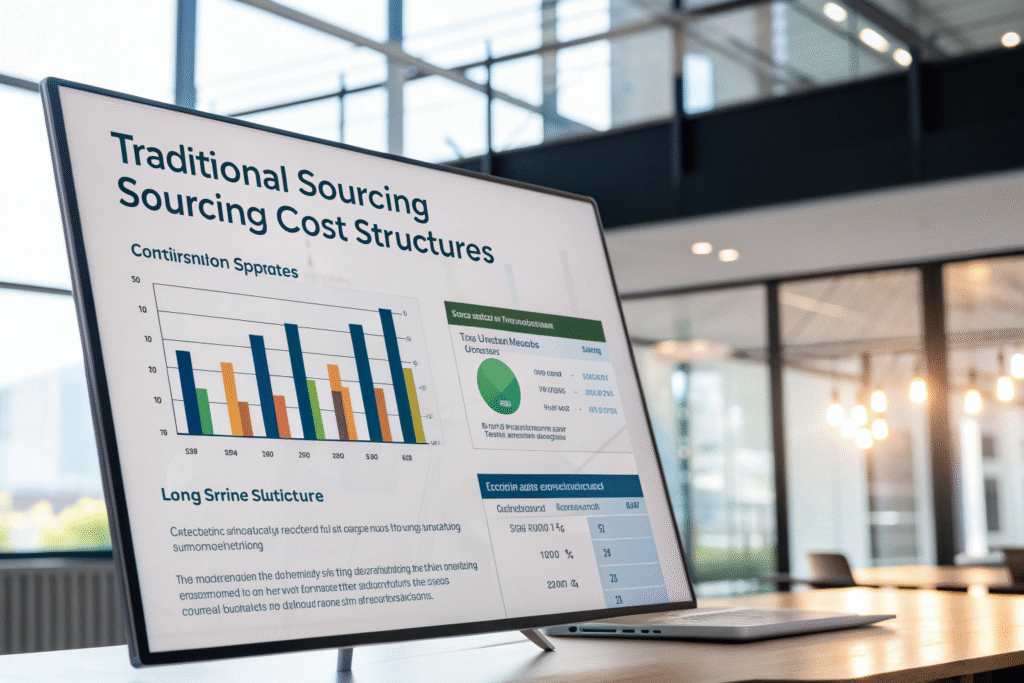

How Do Sustainability Requirements Affect Cost Structures?

Sustainability implementation significantly affects cost structures throughout the supply chain, creating both challenges and opportunities for accessory manufacturers. Understanding these financial implications is essential for developing viable sustainable sourcing strategies.

The cost impact of sustainability extends beyond material premiums to include certification expenses, monitoring systems, process modifications, and compliance management.

What Are the True Costs of Sustainable Sourcing?

The true costs of sustainable sourcing include direct expenses for certified materials, auditing, and compliance, as well as indirect costs for system implementation, training, and process modification. Understanding these cost components helps develop accurate pricing and business models.

Our experience implementing sustainable sourcing initiatives has revealed several key cost factors. Premiums for certified sustainable materials typically range from 15-40% depending on the material and certification requirements. Third-party auditing and certification costs add recurring expenses that must be factored into pricing. Investments in monitoring technology, data management systems, and reporting infrastructure represent significant capital and operational expenditures. However, these costs are often offset by efficiency improvements, waste reduction, and enhanced brand relationships that create long-term value. The evolving regulatory landscape, particularly in European markets, is making these investments increasingly necessary for market access.

How Can Brands Manage Price Premiums for Sustainable Products?

Managing price premiums for sustainable products requires strategic approaches that balance consumer price sensitivity with the real costs of responsible production. Successful strategies communicate value effectively while optimizing production efficiencies.

We've helped our clients implement several strategies for managing sustainability costs while maintaining market competitiveness. Phased implementation allows brands to introduce sustainable elements gradually while educating consumers about their value. Value engineering identifies opportunities to optimize designs for both sustainability and production efficiency. Transparent communication helps consumers understand what they're paying for and why sustainable products command premium pricing. Strategic material selection combines high-impact sustainable elements with cost-effective basics to balance pricing and sustainability objectives. For manufacturers, production efficiencies through waste reduction, energy conservation, and process optimization help absorb some sustainability costs without passing them全部 to consumers.

Conclusion

Sustainable fashion movements are fundamentally transforming accessory sourcing by introducing new environmental standards, social requirements, and circular principles into supply chain management. This transformation represents both a significant challenge and opportunity for manufacturers who must adapt to evolving expectations while maintaining quality, cost-effectiveness, and reliability. The manufacturers who thrive in this new landscape will be those who view sustainability not as a compliance burden but as a driver of innovation and value creation.

At AceAccessory, we've embraced this transformation by integrating sustainable practices throughout our operations, from material sourcing and production to worker welfare and environmental management. Our facility in Zhejiang has implemented comprehensive systems to meet the growing demand for responsibly produced accessories while maintaining the quality and reliability our clients expect. We understand that sustainable sourcing requires ongoing commitment, investment, and collaboration across the supply chain.

If you're looking for a manufacturing partner who understands the complexities of sustainable accessory sourcing and can help you meet your environmental and social goals, we invite you to experience the shanghaifumaoclothing difference. Our team combines technical expertise with sustainable manufacturing capabilities to create products that align with modern values. For personalized assistance with your sustainable sourcing needs, please contact our Business Director Elaine at elaine@fumaoclothing.com. Let us show you how our approach to responsible manufacturing can support your brand's sustainability journey while delivering the quality and value your customers expect.