Canvas bags have become ubiquitous in fashion, retail, and daily life due to their durability, versatility, and eco-friendly appeal. Understanding the materials and manufacturing processes behind these popular bags reveals why they've become a staple across global markets. From natural fiber constructions to technical treatments, canvas bag production combines traditional methods with modern innovations.

Canvas bags primarily utilize cotton, linen, or blended fabrics in various weights and treatments, manufactured through processes including weaving, cutting, sewing, and finishing. At AceAccessory, a core brand of shanghaifumaoclothing https://shanghaiGarment.com, our canvas bag production incorporates both traditional craftsmanship and advanced manufacturing techniques to create products that meet diverse market needs while maintaining quality and durability standards.

This comprehensive guide examines the materials, manufacturing processes, and specialized treatments used in canvas bag production, providing insights into how these popular accessories are created from raw materials to finished products.

What Raw Materials Are Used in Canvas Bag Production?

The foundation of any canvas bag begins with raw material selection, which determines the bag's characteristics, durability, and appropriate applications. Different materials offer varying benefits for specific use cases and market segments.

Primary materials include natural cotton canvas, blended fabrics, technical treated canvases, and eco-friendly alternatives. At AceAccessory, we carefully select materials based on the intended bag purpose, balancing factors like weight, texture, strength, and sustainability to meet our clients' specific requirements.

How is Cotton Canvas Fabric Created?

Cotton canvas fabric begins with raw cotton that undergoes ginning to remove seeds, followed by spinning into yarn. The yarn is then woven using plain or duck weave techniques that create the characteristic tight, durable fabric. Our standard canvas weights range from 8-15 ounces per square yard, with heavier weights used for structural bags and lighter weights for fashion-oriented designs. The weaving process creates the fundamental strength that makes canvas ideal for bags, with the International Cotton Association providing grading standards that ensure consistent quality in our raw materials.

What Are the Characteristics of Blended Canvas Materials?

Blended canvas materials combine cotton with synthetic fibers like polyester or nylon to enhance specific properties:

- Polyester blends improve water resistance, color retention, and mildew resistance

- Nylon blends increase tear strength and abrasion resistance

- Rayon blends enhance drape and softness for fashion applications

Our blended canvases typically maintain at least 60% natural fiber content to preserve the authentic canvas character while gaining performance benefits from synthetic components. These materials undergo rigorous testing to ensure the blends perform consistently under various conditions.

What Manufacturing Processes Transform Fabric into Bags?

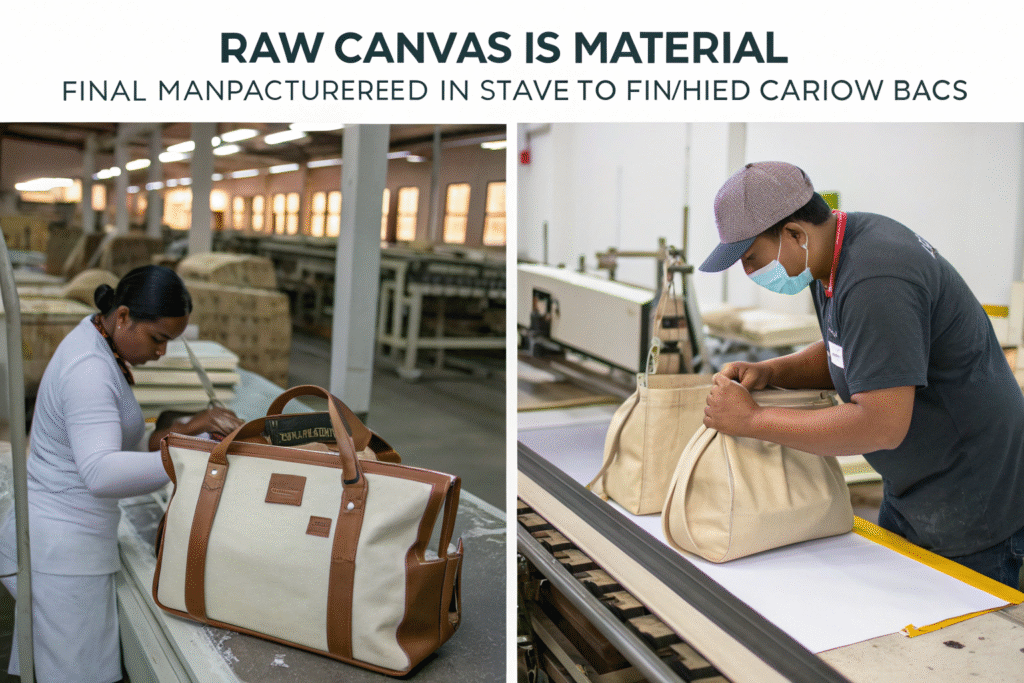

The transformation from raw canvas material to finished bags involves multiple manufacturing stages, each requiring specialized equipment and skilled craftsmanship. These processes determine the final product's quality, durability, and aesthetic appeal.

Key manufacturing stages include fabric treatment, pattern cutting, assembly sewing, hardware attachment, and quality control. At AceAccessory, our manufacturing facilities integrate these processes through streamlined production lines that maintain efficiency while ensuring attention to detail at each stage.

How Does Pattern Cutting Optimize Material Usage?

Pattern cutting optimizes material usage through computerized nesting software that arranges pattern pieces to minimize waste. Our cutting process involves:

- Fabric spreading in multiple layers for efficient cutting

- Computer-guided cutting for precision and consistency

- Marker optimization to achieve 85-90% material utilization

- Quality inspection of each cut piece before assembly

This systematic approach reduces material waste by 15-20% compared to manual cutting methods while ensuring consistent sizing and reducing production costs. The efficiency of this process directly impacts both sustainability and profitability.

What Sewing Techniques Ensure Durability?

Sewing techniques critically impact bag durability through:

- Reinforced stitching at stress points using box or bar tack patterns

- Appropriate stitch density (8-12 stitches per inch) for the fabric weight

- Thread selection matching synthetic threads like polyester for strength

- Seam allowance optimization (typically ½ inch) for durability without bulk

Our production lines utilize industrial sewing machines capable of handling multiple fabric layers, with operators trained to identify potential weak points during assembly. Each bag undergoes tension testing to ensure seams meet our strength standards before proceeding to finishing.

What Specialized Treatments Enhance Canvas Bag Performance?

Specialized treatments applied to canvas bags significantly enhance their performance, appearance, and longevity. These processes transform basic canvas into functional, market-ready products with improved characteristics.

Common treatments include water resistance applications, color fastness improvements, texture modifications, and protective coatings. At AceAccessory, we select treatments based on the bag's intended use, ensuring appropriate performance enhancements without compromising the natural appeal of canvas materials.

How is Water Resistance Applied to Canvas?

Water resistance is applied to canvas through several methods:

- Wax treatments using paraffin or beeswax for traditional water resistance

- Chemical coatings like polyurethane for more consistent protection

- Nanotechnology treatments that create hydrophobic surfaces

- Laminated membranes for technical applications requiring complete waterproofing

Our water resistance treatments undergo spray testing to verify performance, with most treatments maintaining effectiveness through 20-30 cleaning cycles. We carefully balance environmental considerations with performance requirements when selecting water resistance methods.

What Printing and Dyeing Methods Are Used?

Printing and dyeing methods for canvas bags include:

- Screen printing for bold, opaque designs with excellent color fastness

- Digital printing for complex, multi-color patterns with photographic quality

- Yarn dyeing for consistent color throughout the fabric structure

- Piece dyeing for solid colors after weaving completion

- Natural dyeing using plant-based colorants for eco-friendly options

Each method offers different advantages in color vibrancy, durability, and cost efficiency. Our printing processes follow Global Organic Textile Standard guidelines when using organic materials, ensuring environmentally responsible production from dye selection through wastewater management.

How Are Handles and Hardware Integrated?

The integration of handles and hardware represents a crucial stage in canvas bag manufacturing, where functional elements combine with the fabric body to create a complete, usable product. These components significantly impact both aesthetics and functionality.

Handle types include fabric straps, leather accents, webbing constructions, and rope elements, while hardware encompasses zippers, buckles, D-rings, and magnetic closures. Our component selection process balances aesthetic appeal with functional requirements and cost considerations.

What Methods Secure Handles to Bag Bodies?

Handle attachment methods vary based on design and intended use:

- Sewn attachments with reinforced stitching for fabric handles

- Rivet reinforcement at stress points for heavy-duty applications

- Bar tack stitching at connection points for maximum strength

- Modular systems allowing handle interchangeability

Our handle attachments undergo rigorous pull testing, with standard bags required to withstand 40-50 pounds of force and heavy-duty designs tested to 100+ pounds. This ensures handles maintain integrity under normal usage conditions, including carrying heavy loads.

How is Hardware Selected and Attached?

Hardware selection and attachment involves:

- Material compatibility matching hardware finish to bag style

- Load capacity ensuring hardware can withstand intended usage

- Corrosion resistance particularly for bags used in varied environments

- Aesthetic coordination with overall bag design

Our hardware attachment methods include sewing, riveting, and screw fastening based on the specific component and bag design. Each attachment point undergoes stress testing to identify potential failure points before full production begins. Verify our durable-component canvas bags: rivet-reinforced handle canvas bags, high-quality hardware canvas bags, custom handle/hardware services.

What Quality Control Processes Ensure Product Excellence?

Quality control processes throughout canvas bag manufacturing ensure consistent excellence in the final products. These systematic checks identify issues at multiple production stages rather than only at completion.

Quality verification includes material inspection, in-process checks, finished product evaluation, and performance testing. At AceAccessory, our quality management system implements checks at each production stage, with documentation maintained for traceability and continuous improvement.

What Standards Govern Canvas Bag Manufacturing?

Canvas bag manufacturing follows several industry standards:

- ASTM D4037 for fabric performance characteristics

- ISO 9001 for quality management systems

- CPSIA compliance for bags marketed to children

- OEKO-TEX certification for material safety

Our compliance with these standards provides customers with confidence in product safety, durability, and consistent quality. Regular internal and third-party audits verify ongoing compliance across our production facilities.

How is Final Product Quality Verified?

Final product quality verification includes:

- Dimensional accuracy checks against specification tolerances

- Stitch quality inspection for consistency and integrity

- Hardware function testing for smooth operation

- Load testing to verify structural strength

- Color fastness evaluation against rubbing and washing

Each bag undergoes individual inspection before packaging, with random samples from each production batch subjected to more rigorous testing. This comprehensive approach ensures only products meeting our quality standards reach customers.

Conclusion

Canvas bag manufacturing involves a sophisticated combination of material science, traditional craftsmanship, and modern manufacturing processes. From selecting appropriate raw materials through specialized treatments and quality verification, each stage contributes to creating functional, durable products that meet diverse market needs. Understanding these processes helps appreciate the value proposition of quality canvas bags while informing better purchasing decisions for consumers and retailers alike. To explore bulk pricing, download technical data sheets, or request free product samples for quality verification, visit shanghaiGarment.com’s canvas bag sourcing hub.

If you're interested in sourcing or developing canvas bags with specific material characteristics or manufacturing approaches, we invite you to contact our Business Director, Elaine. She and our AceAccessory team can provide expert guidance on material selection, production processes, and customization options tailored to your market needs. Reach out to Elaine at: elaine@fumaoclothing.com.